(Continued)

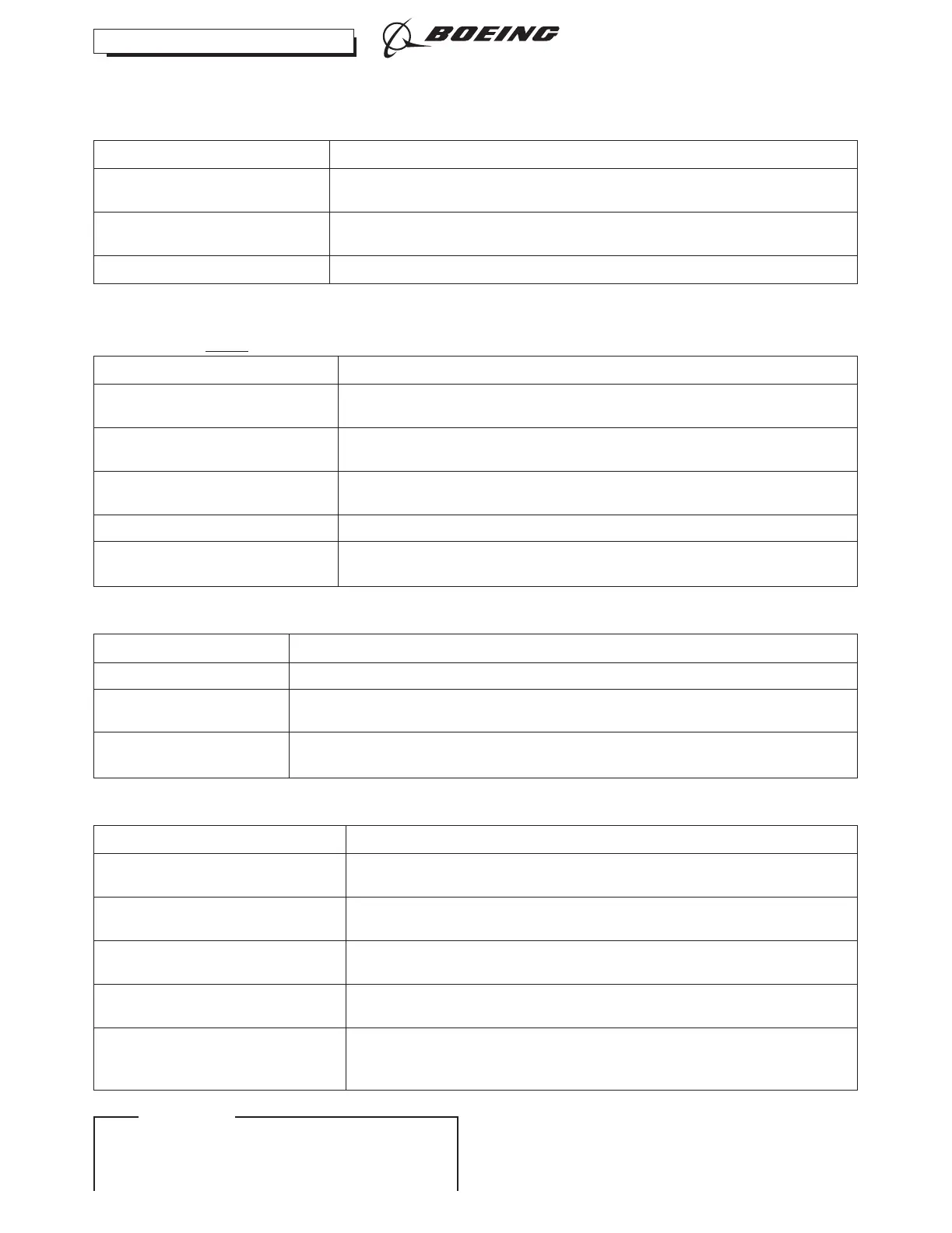

Condition Maximum Serviceable Limits

Nicks and scratches in Area A

(Figure 603)

Permitted, if they are less than 0.03 inch (0.8 mm) in depth, and 0.5 inch (12.7 mm)

in length. They must have a minimum separation of 0.5 inch (12.7 mm).

Nicks and scratches in Area B

(Figure 603)

Permitted, one in each 1.0 square inch (6.45 square cm). They must be less than

0.015 inch (0.4 mm) in depth and 0.5 inch (12.7 mm) in length.

Corrosion (discoloration) Permitted, if there are no scales or pits.

SUBTASK 72-33-04-216-013-G00

(6) Visually examine the pylon panels for the conditions that follow:

NOTE: Also examine the pylon panels that are aft of struts No. 1 and No. 7.

Condition Maximum Serviceable Limits

Cracks in the screw holes Permitted, one in each screw hole, if the adjacent screw holes are not cracked.

The cracks must be less than 0.25 inch (6.4 mm) in length.

Cracks in the other areas (not in the

screw holes)

Not permitted.

Nicks and scratches Permitted, if they are less than 0.03 inch (0.8 mm) in depth, 0.06 inch (1.5 mm) in

width, and 3.0 inches (76.2 mm) in length (after you remove the high metal).

Screws that are loose or gone Not permitted. You must tighten or replace the screws.

Pylon seals on the thrust reverser

that are damaged or gone

Not permitted. Repair or replace (PAGEBLOCK 78-00-00/801).

SUBTASK 72-33-04-216-014-G00

(7) Visually examine the service tubes and connections for the conditions that follow:

Condition Maximum Serviceable Limits

Cracks Not permitted.

Nicks and scratches Permitted if they are less than 0.010 inch (0.25 mm) in depth (after you remove the high

metal). The nicks and scratches must not go fully across the mating surface.

Dents Permitted, if the dents have a smooth contour, and are less than 0.06 inch (1.5 mm) in

depth. The contour rate must be less than 0.010 inch (0.25 mm) for each inch.

SUBTASK 72-33-04-216-015-G00

(8) Visually examine the case for the conditions that follow:

Condition Maximum Serviceable Limits

Cracks (all areas other than the

circumferential plane of the OGV)

One in ten bolts on the forward flange can have a crack that is less than 0.25

inch (6.4 mm) in length.

One in five lightening holes in the case rib can have a crack that is less than 0.25

inch (6.4 mm) in length.

One crack that goes through the flange and into the case skin is permitted. It

must be less than 3.0 inch (76 mm) in length.

Cracks in the circumferential plane of

the OGV

Not permitted. Refer to the Continue-In-Operation Limits

(TASK 72-00-00-206-054-G00).

Dents Permitted, if they have a smooth contour and are less than 0.19 inch (4.8 mm) in

depth. There must be a minimum separation of 4 inches (102 mm) between the

dents.

767

AIRCRAFT MAINTENANCE MANUAL

CF6-80A SERIES ENGINES

72-33-04

NoC

Page 606

D633T1B7 Dec 22/2016

ECCN 9E991 BOEING PROPRIETARY - Copyright © Unpublished Work - See title page for details

EFFECTIVITY

ABX 001-007, 011, 012, 016-019, 021, 022, 025, 101,

109, 114, 115, 314-999

Loading...

Loading...