Trouble-

shooting

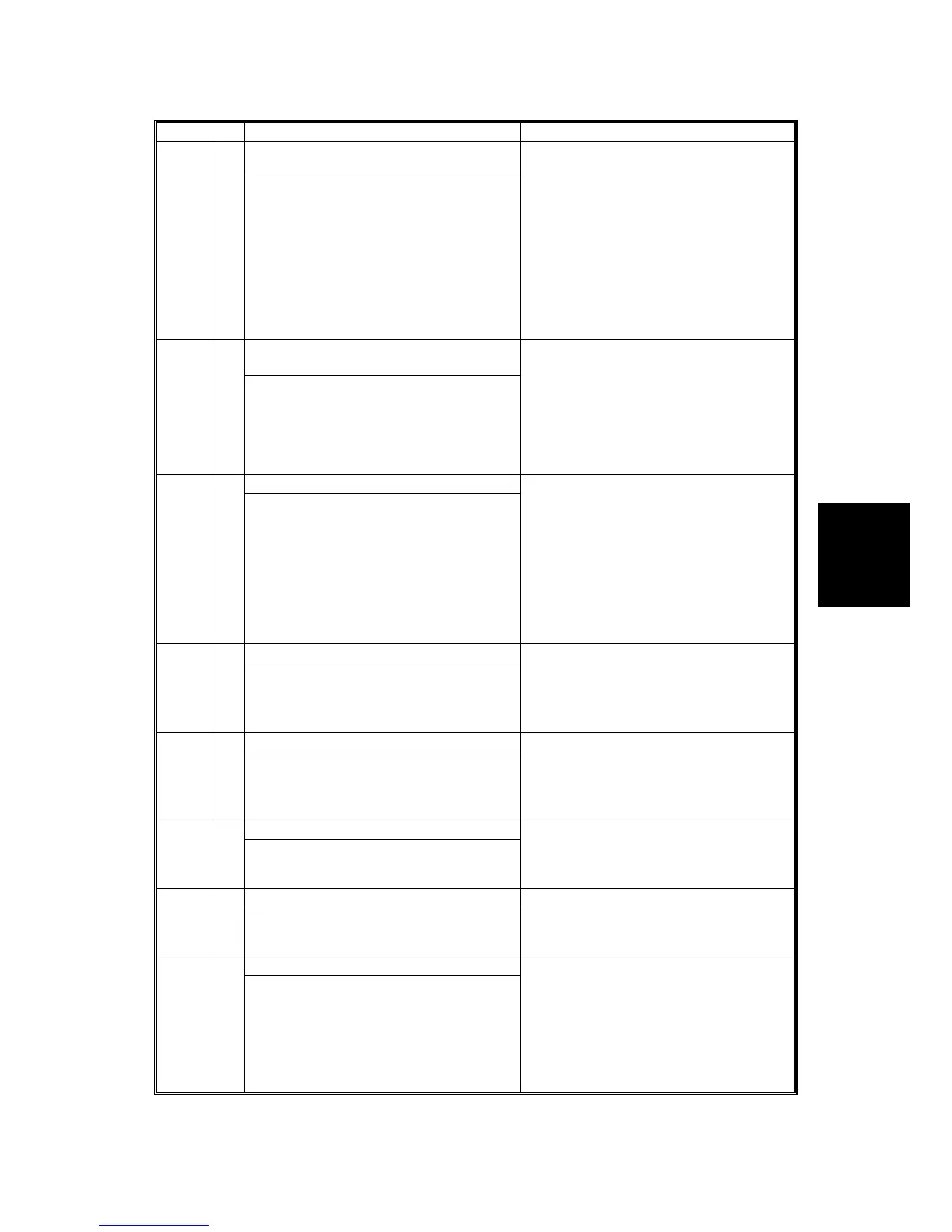

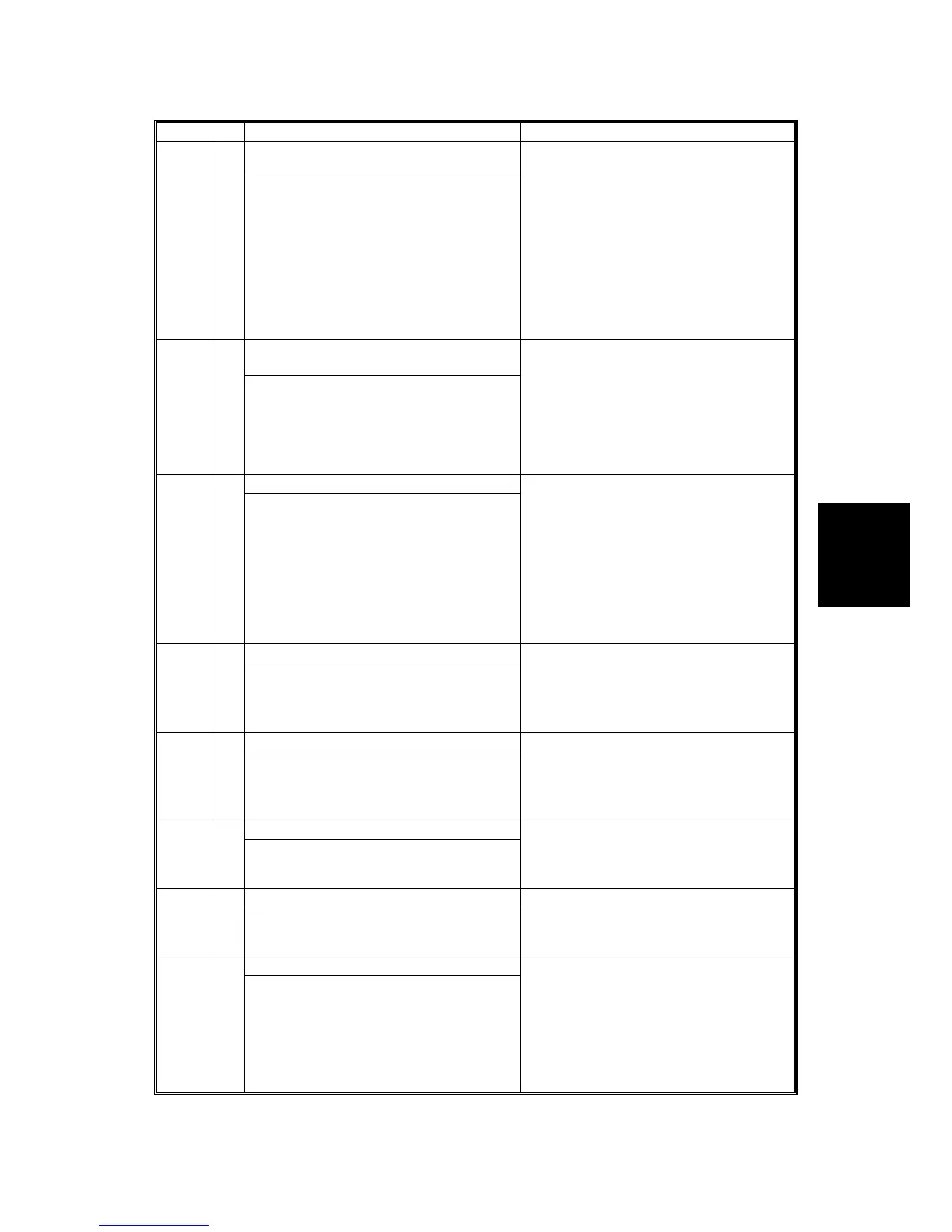

SERVICE CALL CONDITIONS

SM 4-5 B079/B082

Code No. Symptom Possible Cause

ID sensor, LED current abnormal at

initialization

353 C

One of the following ID sensor

output voltages is detected at ID

sensor initialization.

1) Vsg < 4.0V when the maximum

PWM input (255) is applied to

the ID sensor.

2) Vsg ≥ 4.0V when the minimum

PWM input (0) is applied to the

ID sensor.

ID sensor defective

ID sensor harness defective

ID sensor connector defective

Poor ID sensor connection

I/O board (IOB) defective

Exposure system defective

High voltage supply board defective

Dirty ID sensor

ID sensor timeout abnormal at

adjustment

354 C

Vsg falls out of the adjustment target

(4.0 ± 0.2V) at the start of Vsg checking

after 20 seconds

ID sensor defective

ID sensor harness defective

ID sensor connector defective

I/O board (IOB) defective

Exposure system defective

Poor ID sensor connector connection

High voltage supply board defective

Dirty ID sensor

TD sensor error: Test value abnormal 390 C

The TD sensor output voltage is less

than 0.5V or more than 5.0V after 10

consecutive times during copying.

TD sensor defective

TD sensor not connected or connector

damaged

Poor connection between the TD

sensor and the I/O board (IOB)

I/O board (IOB) defective

Toner supply defective

TD sensor error: Auto adjust error 391 C

During automatic adjustment of the TD

sensor, output voltage is less than 1.8V

or more than 4.8V during TD sensor

initial setting.

TD sensor abnormal

TD sensor disconnected

Poor TD sensor connection

I/O Board (IOB) defective

Toner supply defective

Development output abnormal 395 C

A development bias leak signal is

detected. High voltage output to the

development unit exceeded the upper

limit (65%) for 60 ms.

High voltage supply board defective

Poor connection at the development

bias terminal

Poor connection at the high voltage

supply board

Transfer roller leak detected 401 C

A transfer roller current leak signal is

detected.

High voltage supply board defective

Poor cable connection or defective

cable

Transfer connector defective

Transfer roller open error 402 C

The transfer roller current feedback

signal is not detected.

High voltage supply board defective

Transfer connector cable defective

Transfer connector defective

Poor PCU connection

Transfer belt position sensor error 403 C

The transfer belt position sensor does

not activate even if the transfer belt

contact clutch has been switched on

twice and rotated once.

Main motor/drive malfunction

Transfer belt contact clutch defective

Harness disconnected

Loading...

Loading...