05-50

SPECIAL SCHEDULED MAINTENANCE

2. Operation in High Salt or High Humidity Environments

In case of aircraft operating in high salt of high humidity environment (e.g. air-

craft operating over salt water), following scheduled maintenance tasks shall be

applied:

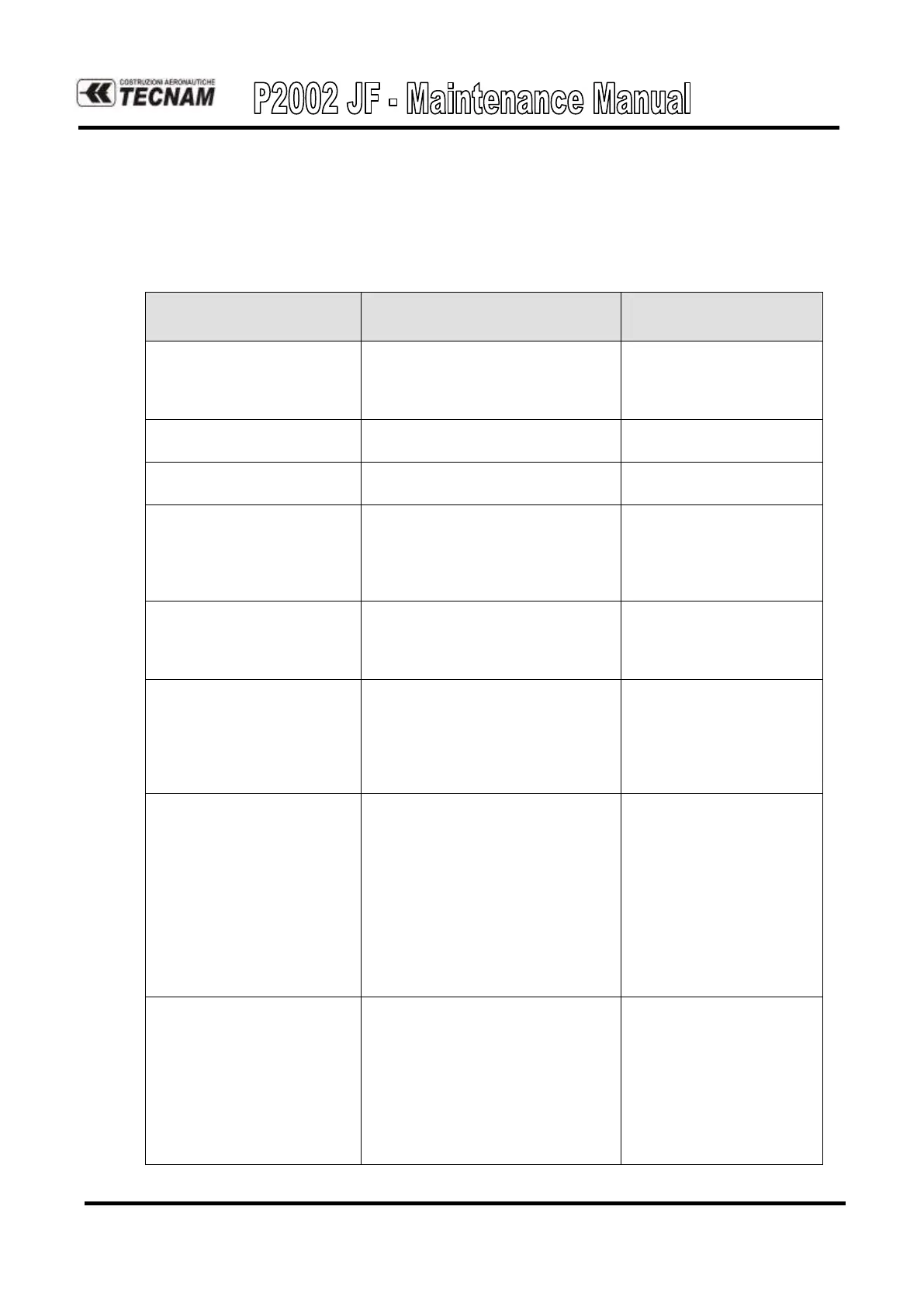

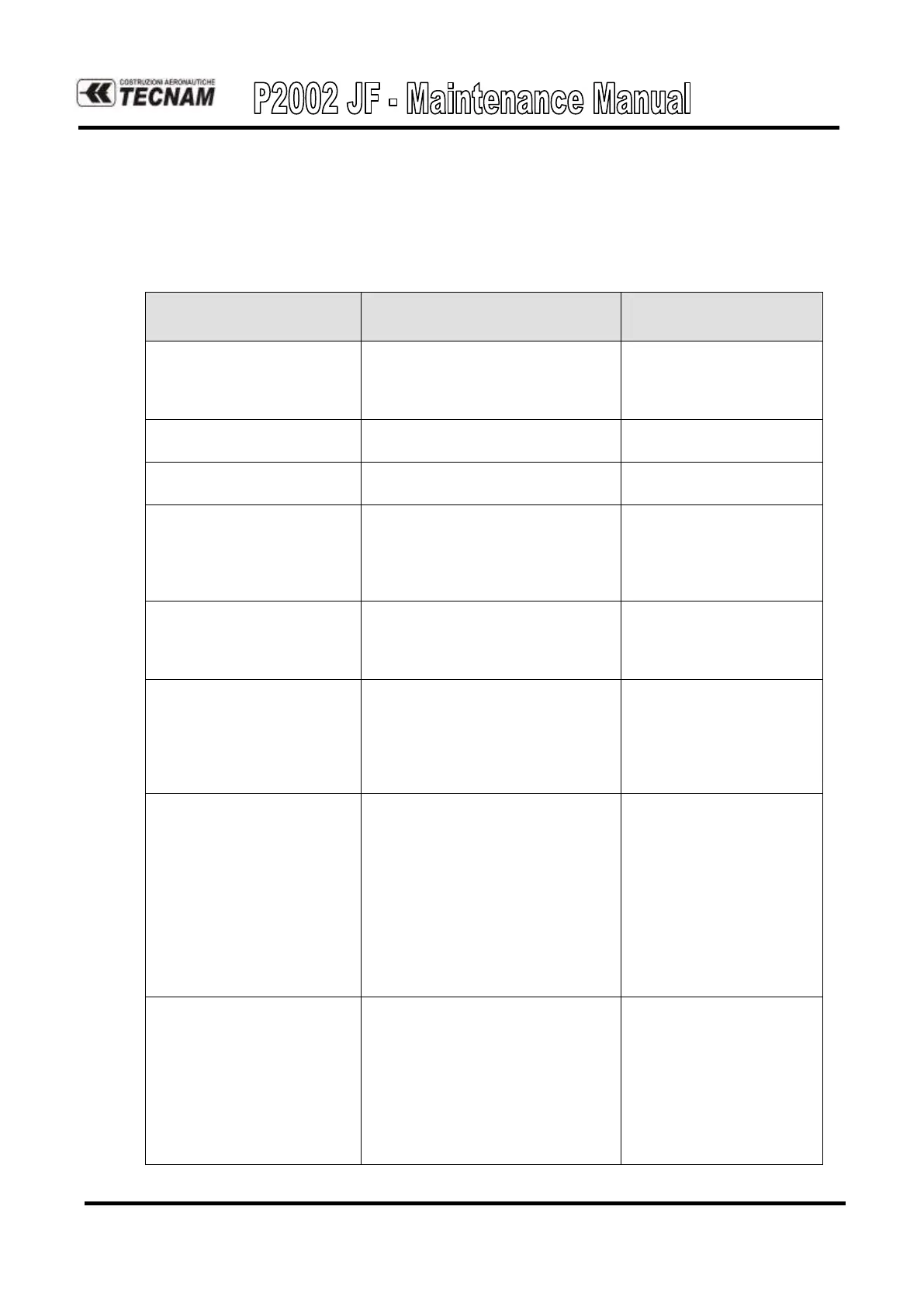

Fuselage, Empennage, Wings

and Control Surfaces

Remove floor panels and exterior ac-

cess plates; inspect for corrosion using

boroscopes, mirrors or other suitable

tools.

Inspect for proper sealing of cases.

Check for corrosion

Inspect upholstery, seat belts and seats

for corrosion and integrity

Visually inspect paint in areas of the

exhaust trails for damage. Visually in-

spect under fairings, around rivet

heads, and in skin crevices, for corro-

sion in areas of engine exhaust trail.

Inspect battery compartment for elec-

trolyte spillage, and condition of pro-

tective paint. Inspect area around bat-

tery vent for corrosion.

Inspect landing gear components for

damage to exterior finish coating and

corrosion. Particular attention should

be given to exposed surfaces, and at-

taching hardware; ribs, and lower skin

surfaces

Inspect control cables for bare spots in

the preservative coating and corrosion.

If external corrosion is found, relieve

tension on the cable and check internal

strands for corrosion. Cables with cor-

rosion on internal strands should be

replaced. External corrosion should be

removed by a clean, dry, coarse rag or

fiber brush. A preservative should be

applied after removal of external cor-

rosion.

Electrical connectors, switches

and breakers

Inspect electrical connectors for corro-

sion of pins and wires. If the electrical

connector is suspected of having mois-

ture intrusion, disassemble the con-

nector, clean the connector, and in-

spect it for corrosion. Inspect circuit-

breakers, contact points, and switches

for evidence of moisture and corrosive

attack.

Loading...

Loading...