Page 201 2

nd

Edition – Rev 0

27-50

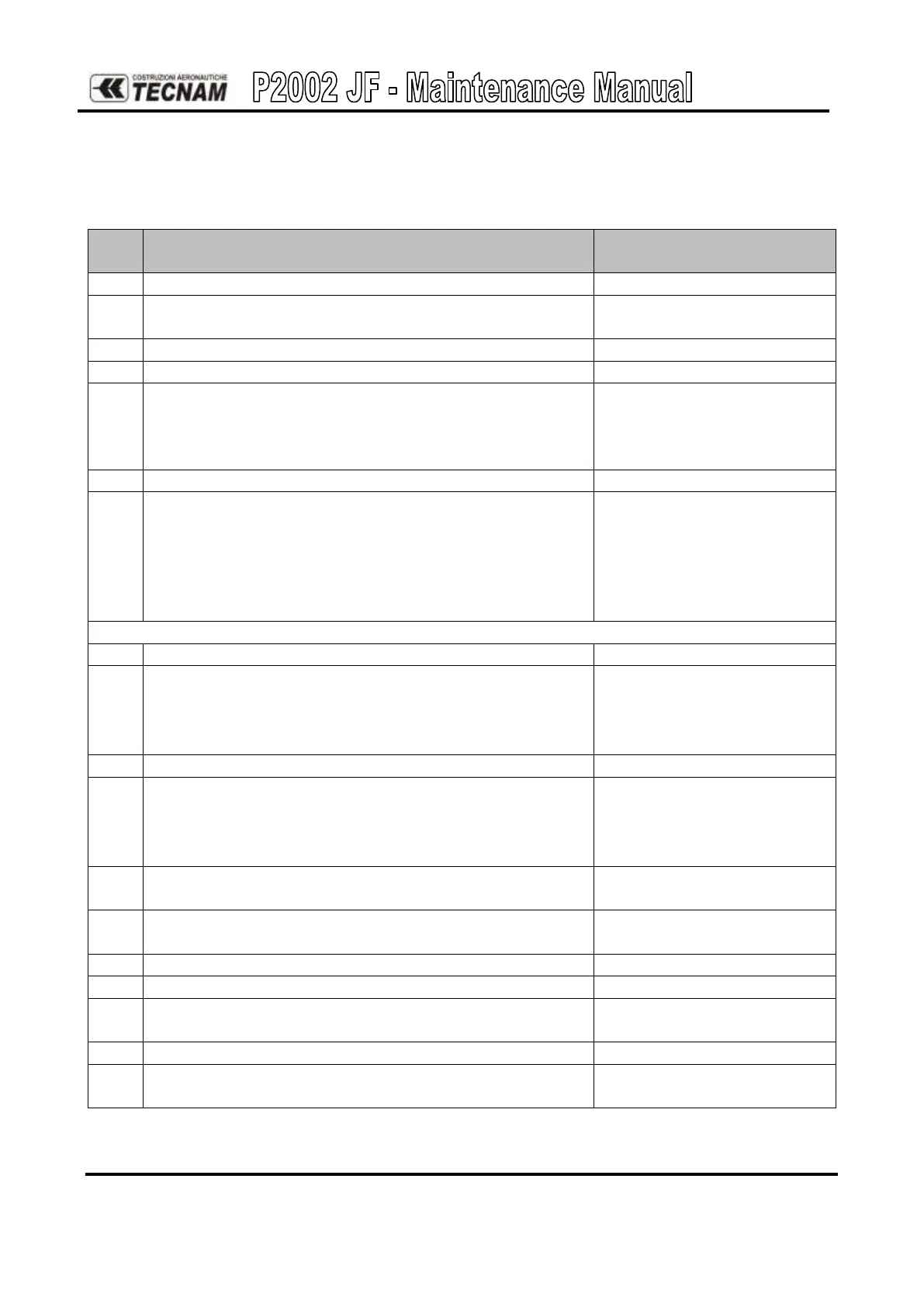

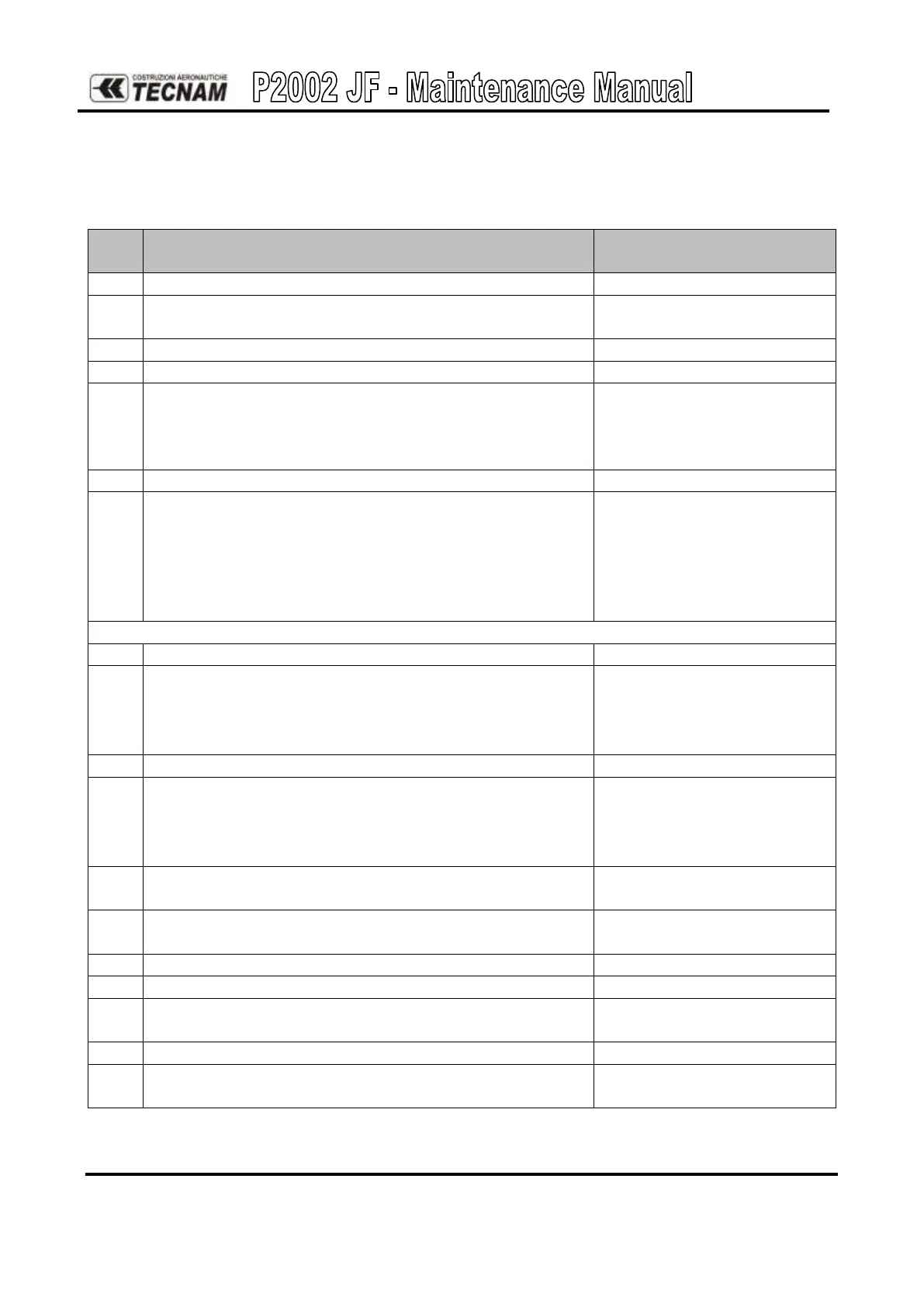

RUDDER –MAINTENANCE PRACTICES

1. RUDDER CONTROL CABLE REPLACEMENT

Additional info &

References

Remove seats, central pad, tapestry and floor panel

Refer to Figure 7. and to

Chapter 12

Open (10) (7a) (7b) (8a) (8b) inspection caps

Refer to Chapter 25 tab. 8

In (8a) & (8b) inspection cap: cut safety wire, remove

cotter pin, bolt and washer. (pedals without brake pump

shown in figure, same process applicable at pedals with

brake pump).

Refer to Figures:

- 27. item A

- 28.

Unscrew completely turnbuckles to disconnect cable ends

In (10) inspection cap unscrew and remove rudder/rudder

cables attachments:

- Remove cotter pin

- Remove bolt washers and nut

- Pull out cable from its attachment

- Remove from cable the terminal fig. X item B

Refer to Figures:

- 27 .item B

- 29.

- 31.

THESE STEPS ARE APPLICABLE TO LH AND RH RUDDER CABLE

Remove and replace (if required) rudder cables

In (8a) & (8b) inspection cap join LH and RH control

cable to pedals; tighten according standard value,

lubricate with grease.

Refer to Figures:

- 27. item A

- 28.

See chapter 12 and 20

Drive cable trough pulley (rear panel BC2)

Join cable to terminal and terminal to rudder cables

attaching plate; tighten according standard value,

lubricate with grease.

Refer to Figures:

- 29

- 31

See Chapter 12 and 20

Check control cable tension; adjust turnbuckle and apply

safety wire.

See Chapter 20 (See tension

values)

Check for interference between control cable and

structural components

Check rudder travel limits

Close all inspection caps

Install tapestry, floor panel and seats

Refer to Figure 7 and to

Chapter 12

Ensure that pedals movement is smooth and free

Ensure that rudder movement is smooth and free, and no

objects are left inside during replacement

Loading...

Loading...