Page 202 2

nd

Edition – Rev 0

32-40

NOSE LANDING GEAR – MAINTENANCE PRACTICES

3. REMOVAL OF NOSE WHEEL

Procedure

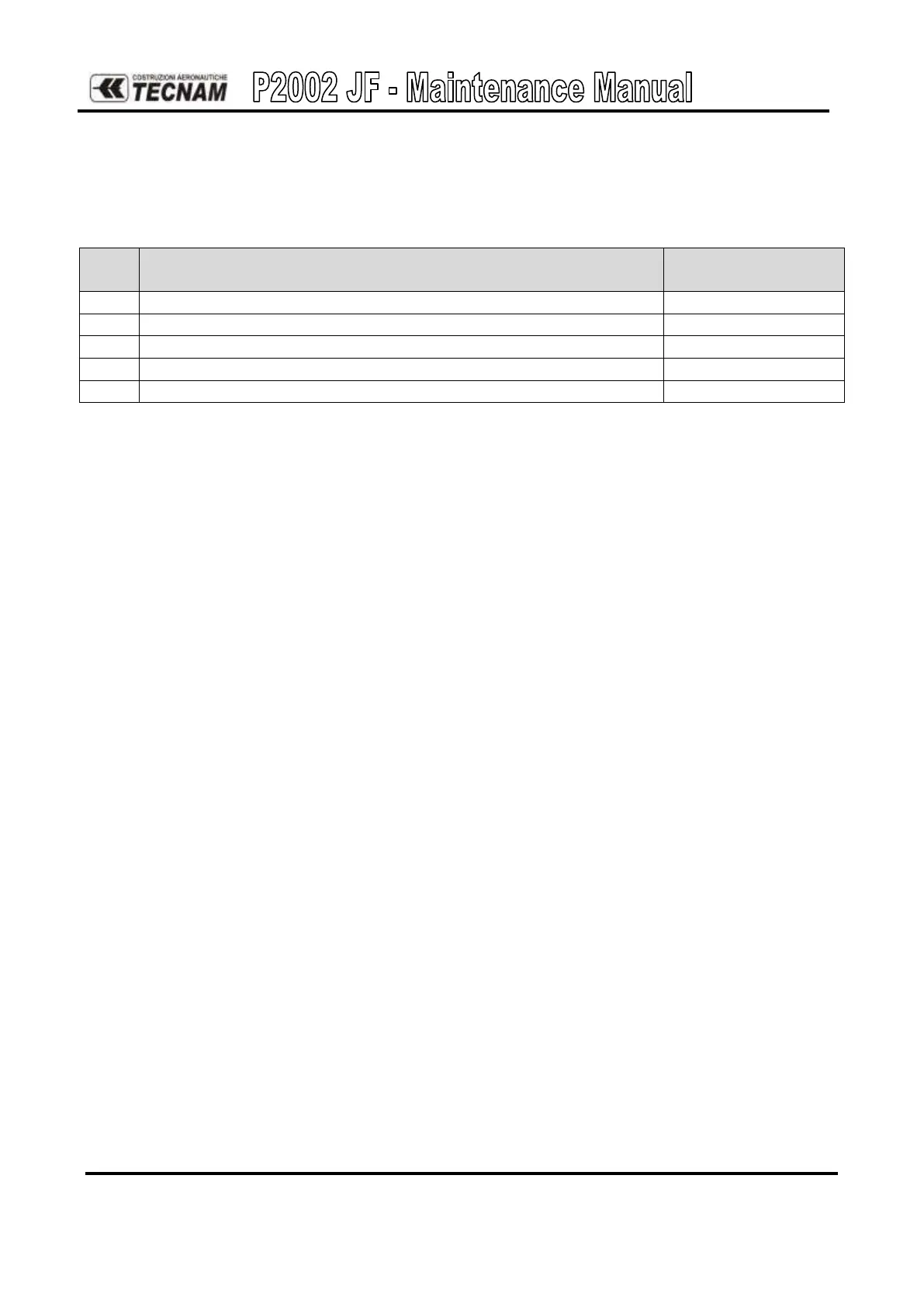

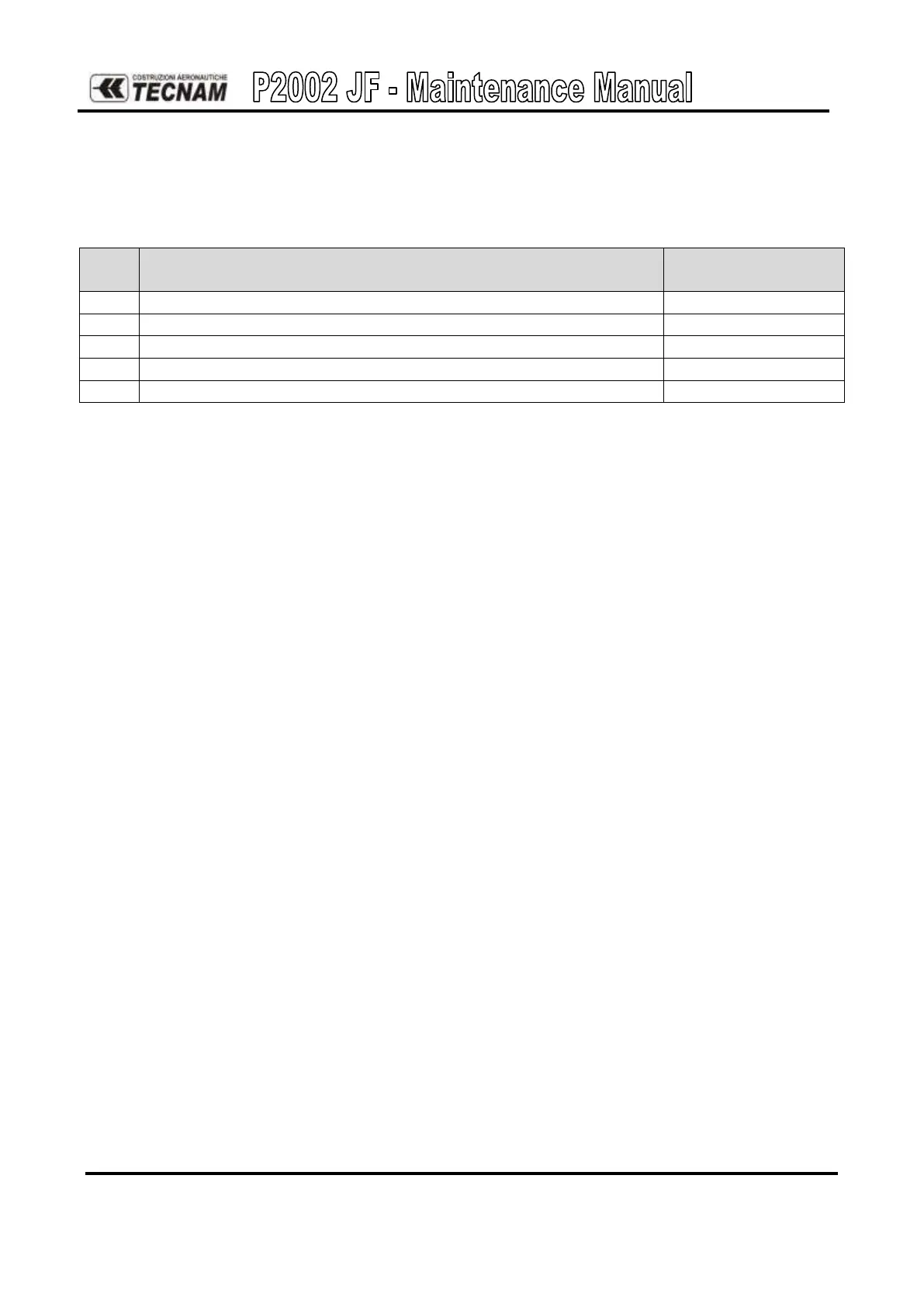

NLG removal

Task description

Additional info &

References

Remove the fairings (2) and (4)

Loosen bolts (5), (7), (8) and (9)

Detach the two wheel forks (10) from each other

4. ON-AIRCRAFT NOSE WHEEL INSPETION

Perform on-aircraft inspection as follows:

(1) Visually inspect the wheels for corrosion, cracks, or other visible damage.

(2) Check wheel nuts to be sure they are properly installed and have not worked

loose. Bolt threads should be flush to 1-1/2 threads extending beyond the nut.

(3) Visually inspect tyres for cuts, flat spots, and tread or sidewall damage.

(4) Check inflation pressure. Proper inflation will provide maximum tyre and

wheel life.

(5) Pressure must be checked when tyres are cool.

(6) If the slippage marks are not in alignment, a detailed inspection must be made,

the reason determined, and if necessary, the condition corrected before the next

flight.

Loading...

Loading...