Page 203 2

nd

Edition – Rev 0

20-20

CONTROL CABLE – MAINTENANCE PRACTICES

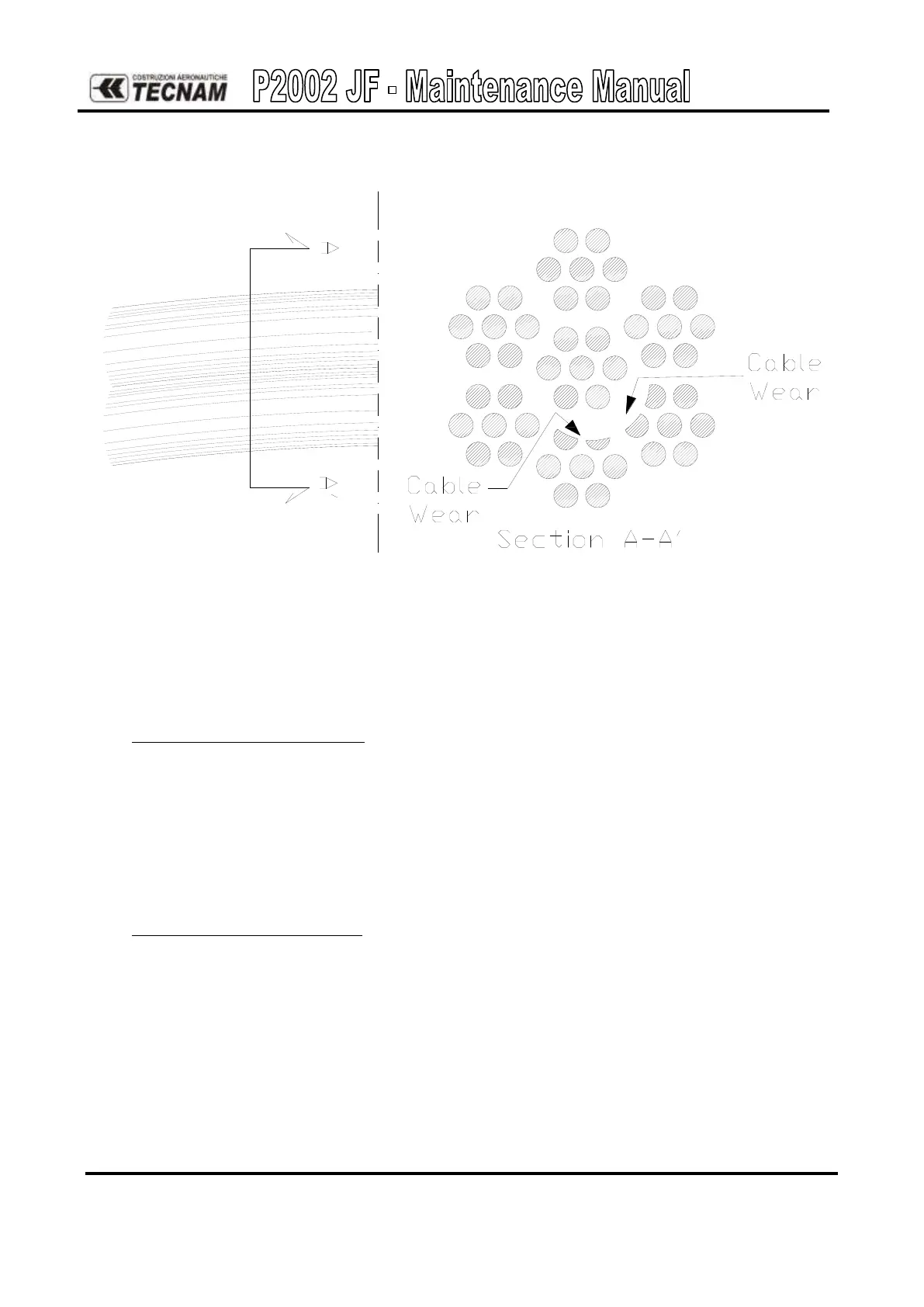

Figure 3. - Internal cables wear

Cable fittings

100 hours standard inspection: check swaged terminal reference marks for any indication of

cable slippage within fitting. Inspect fitting assembly for distortion and/or broken strands at

the terminal. Check that all bearings and swivel fittings (bolted or pinned) pivot freely to

prevent binding and subsequent failure. Check turnbuckles for proper thread exposure and

broken or missing safety wires/clips. Pay particular attention to corrosion and “pitting” on

cable terminals, turnbuckles and cable fittings. Any corrosion or pitting found, requires

replacement of the corroded fitting and/or cable.

100 hours special inspection: for aircraft 15 years old or older, using a 10X magnifier,

visually inspect the entire surface of each cable terminal, turnbuckle, or other cable fitting for

corrosion or cracking. Inspect under safety wire or clips wrapped around the cable or fitting.

Any evidence of corrosion or cracking, however minute, is cause for replacement. A logbook

entry documenting the replacement of a cable terminal, turnbuckle, or other cable fitting

relieves the inspection requirement for that fitting only, until such time as that fitting has been

in service for 15 years.

Loading...

Loading...