05-60

UNSCHEDULED MAINTENACE

05-60 UNSCHEDULED MAINTENANCE

The following inspections are required in response to specific anomalies encountered

during aircraft operation. Note that the items listed herein are guidelines based on past

operating experience. Each operator should closely monitor his own unique operating

conditions/environment and react accordingly to keep his aircraft airworthy.

NOTE: for engine unscheduled maintenance, make

reference to applicable Rotax Engine Maintenance

Manual – last issue.

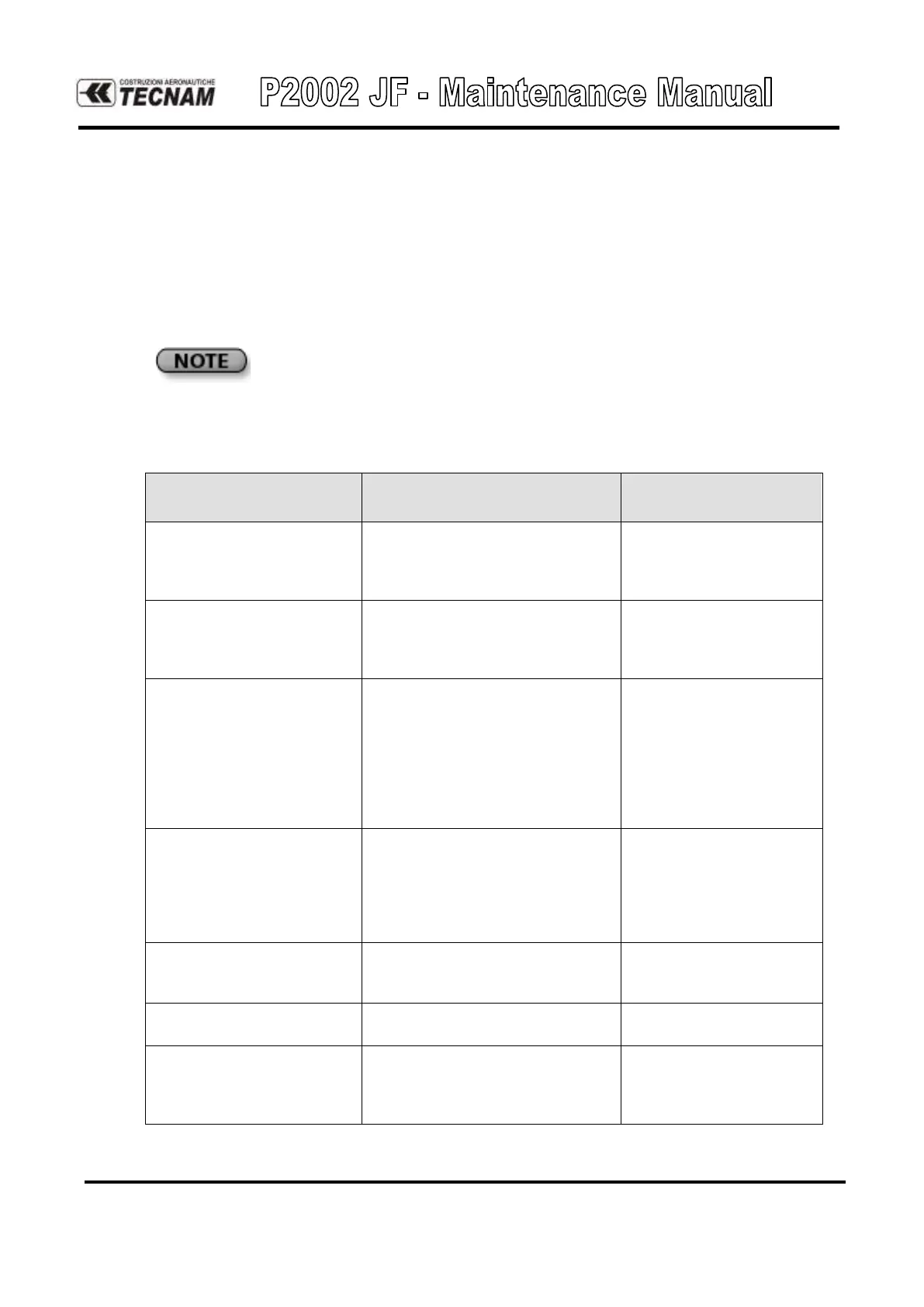

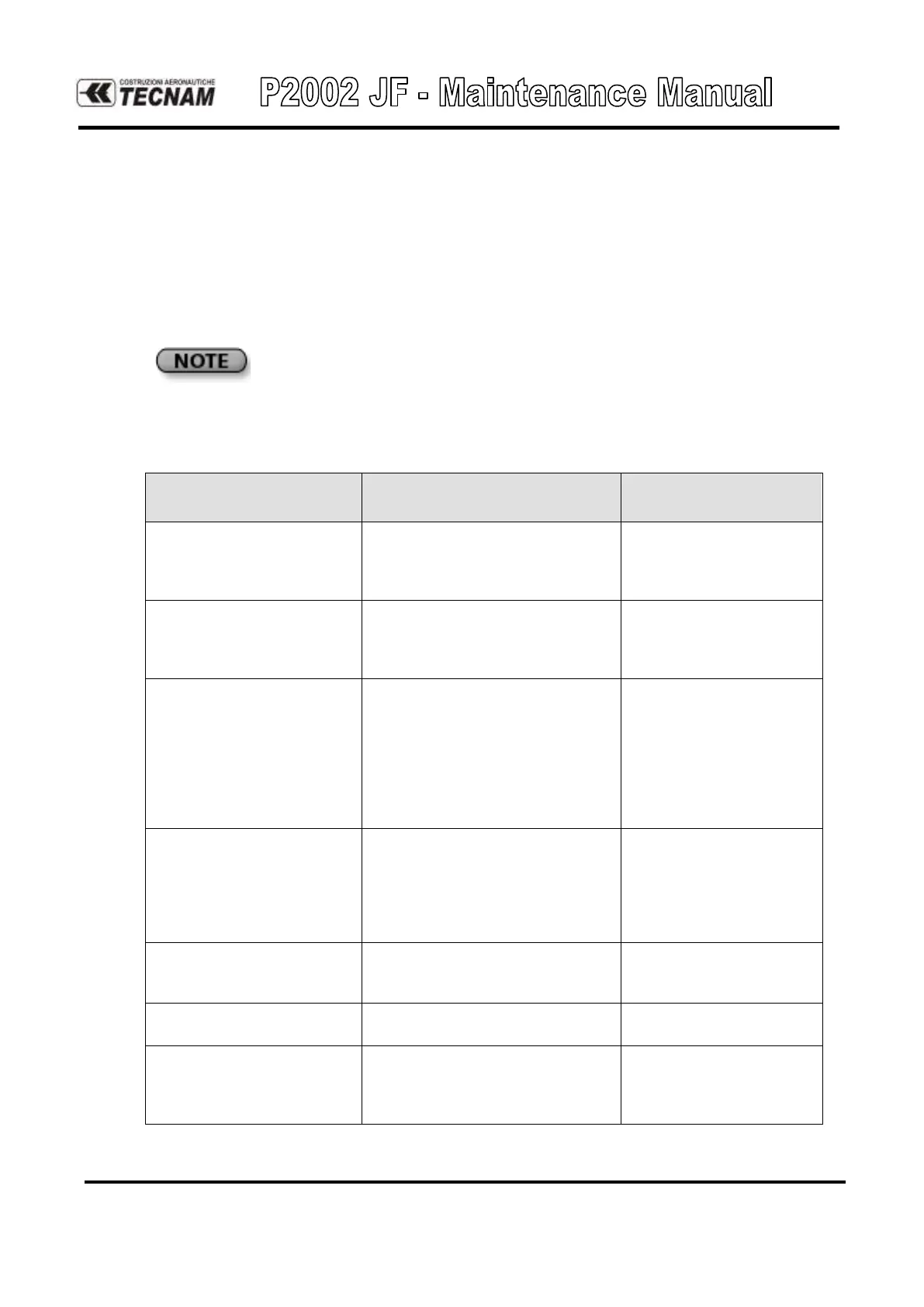

1. Lightning strike

Refer to the inspection require-

ments in the latest revision of the

Hoffman propeller maintenance

manual.

Each occurrence, before

further flight.

See latest revision of appropriate

Rotax Maintenance Manual, ser-

vice bulletins and Overhaul Manu-

al.

Each occurrence, before

further flight.

Electrical and avionics sys-

tem

Inspect and check harness, connec-

tion, and equipment for high volt-

age damage, burns and insulation

degradation. Replace or overhaul

as required. Consult with avionics

vendor(s) for inspections and op-

erational checks. Bench test alter-

nator and voltage regulator(s).

Each occurrence, before

further flight.

All exterior surfaces, skins

and structure

Inspect for burns, evidence of arc-

ing and damage on surface and

bearing. Check for correct material

properties in the area of the strike

path. Degauss engine mount. Re-

place or repair affected areas/parts.

Each occurrence, before

further flight.

Inspect instrumentation, pi-

tot/static, and fuel systems, for

damage and correct operation.

Each occurrence, before

further flight.

Each occurrence, before

further flight.

Inspect all control surface hinges

and bearings, and landing gear and

wheel bearing for pitting and dam-

age. Replace as required.

Each occurrence, before

further flight.

Loading...

Loading...