Page 1 2

nd

Edition – Rev 0

27-30

FLAPS – DESCRIPTION AND OPERATION

27- 30 FLAPS

DESCRIPTION AND OPERATION

The flap system is made up of an electric actuator , a shunt, and by a position

indicator instrument. The actuator is installed in the tail cone in correspondence

with the baggage bulkhead and controls a system of pushrods that initiates flap

extension. Micro-switches positioned within the actuator automatically interrupt

current flow when flaps reach “all-out” or “all-in” positions.

A bowden-type cable issuing from the flap actuator controls flap position indicator located

on the right side of the instrument panel.

Flap extension shunt is supplied by the primary bus bar through a breaker and is located on

the instrument panel.

Shunt must be activated until desired position is reached and read on instrument :0°, TO

(15°) or FULL (40°).

During flap retraction, shunt supplies the actuator until flaps are completely retracted.

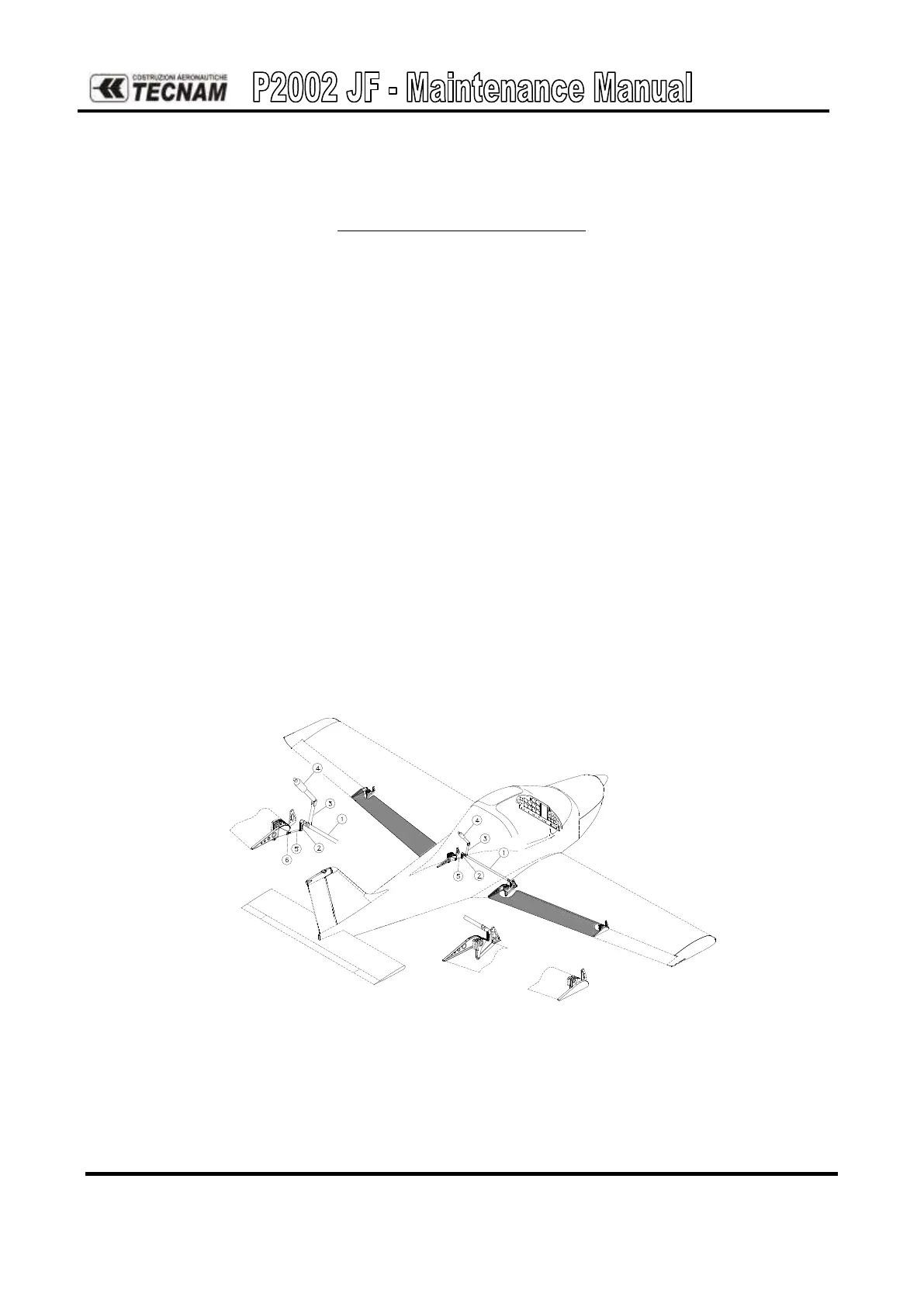

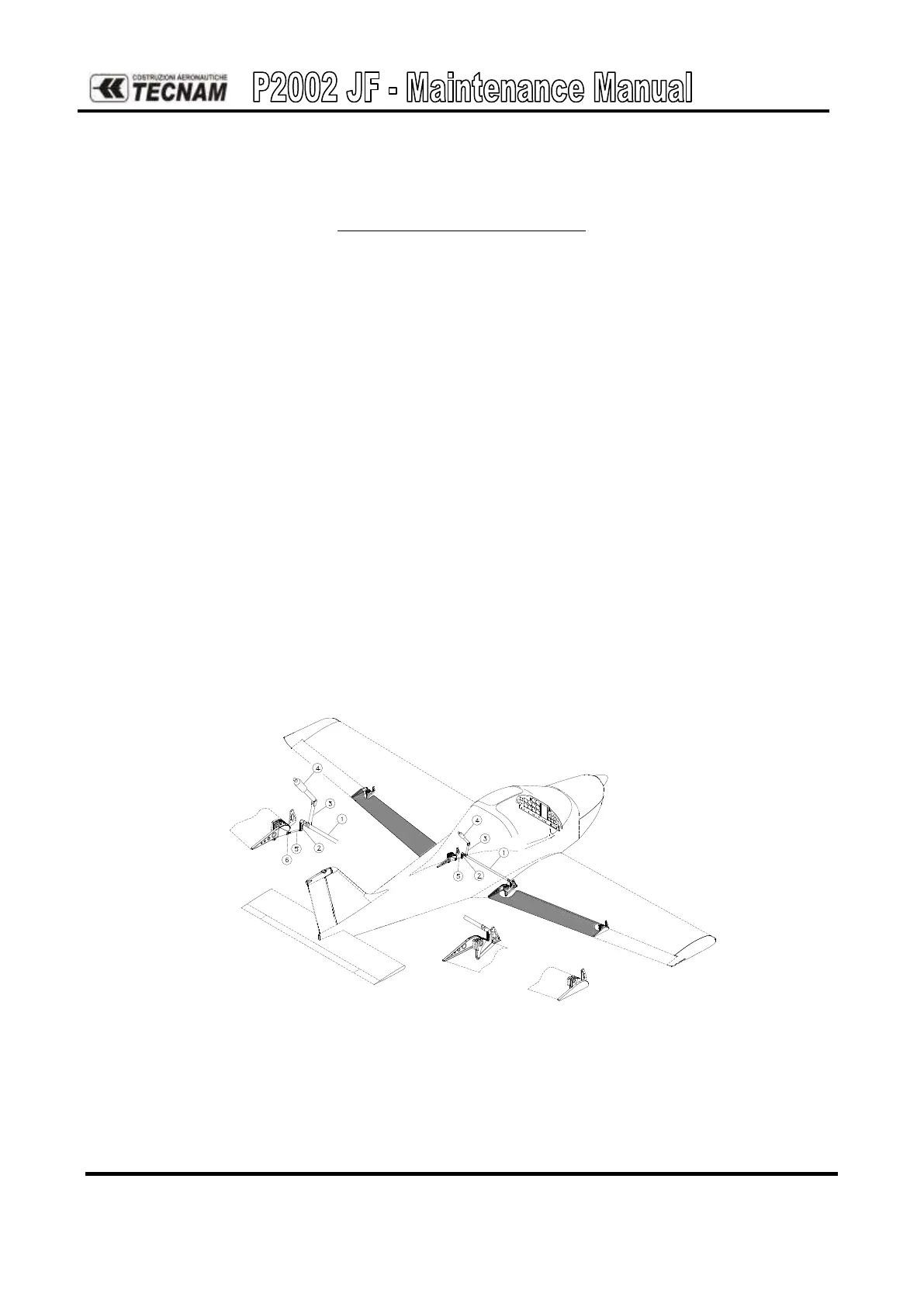

Flap control system is push-pull type. The torque tube (1) is hinged to the cabin truss and

connects the two moving surfaces by two levers (2). An electric linear actuator (4) governed

by a switch on instrument panel controls the torque tube movements via a lever (3).

Two push-pull rods (5) are connected to the ends of the torque tube (1) and are located in the

area between wing and fuselage thus facilitating inspection.

The two push-pull rods controlling flap movement feature an adjustable linkage just before

the roller bearings allowing trailing edge alignment.

Figure 15a. – Flap control

The flaps position indicator is provided on the instruments panel: see Chapter 31.

Loading...

Loading...