Page 204 2

nd

Edition – Rev 0

20-20

CONTROL CABLE – MAINTENANCE PRACTICES

Pulleys

Inspect pulleys for roughness, sharp edges, and presence of foreign material embedded in the

grooves. Examine pulley bearings to assure proper lubrication, smooth rotation, freedom from

flat spots, dirt, and paint spray. Periodically rotate pulleys, which turn through a small arc, to

provide a new bearing surface for the cable. Maintain pulleys alignment to prevent the cable

from riding on flanges and chafing against guards, covers, or adjacent structure. Check all

pulley brackets and guards for damage, alignment and security.

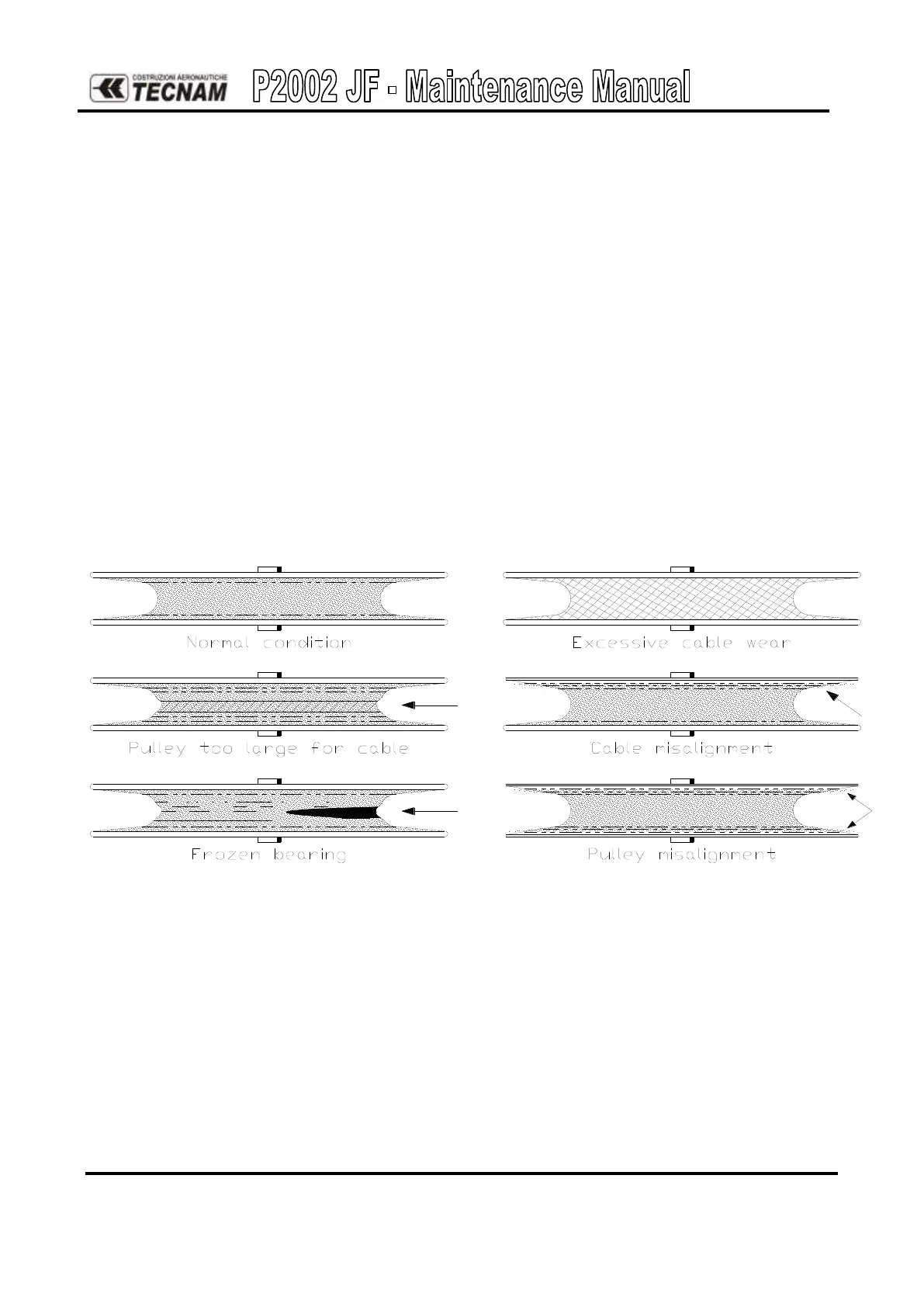

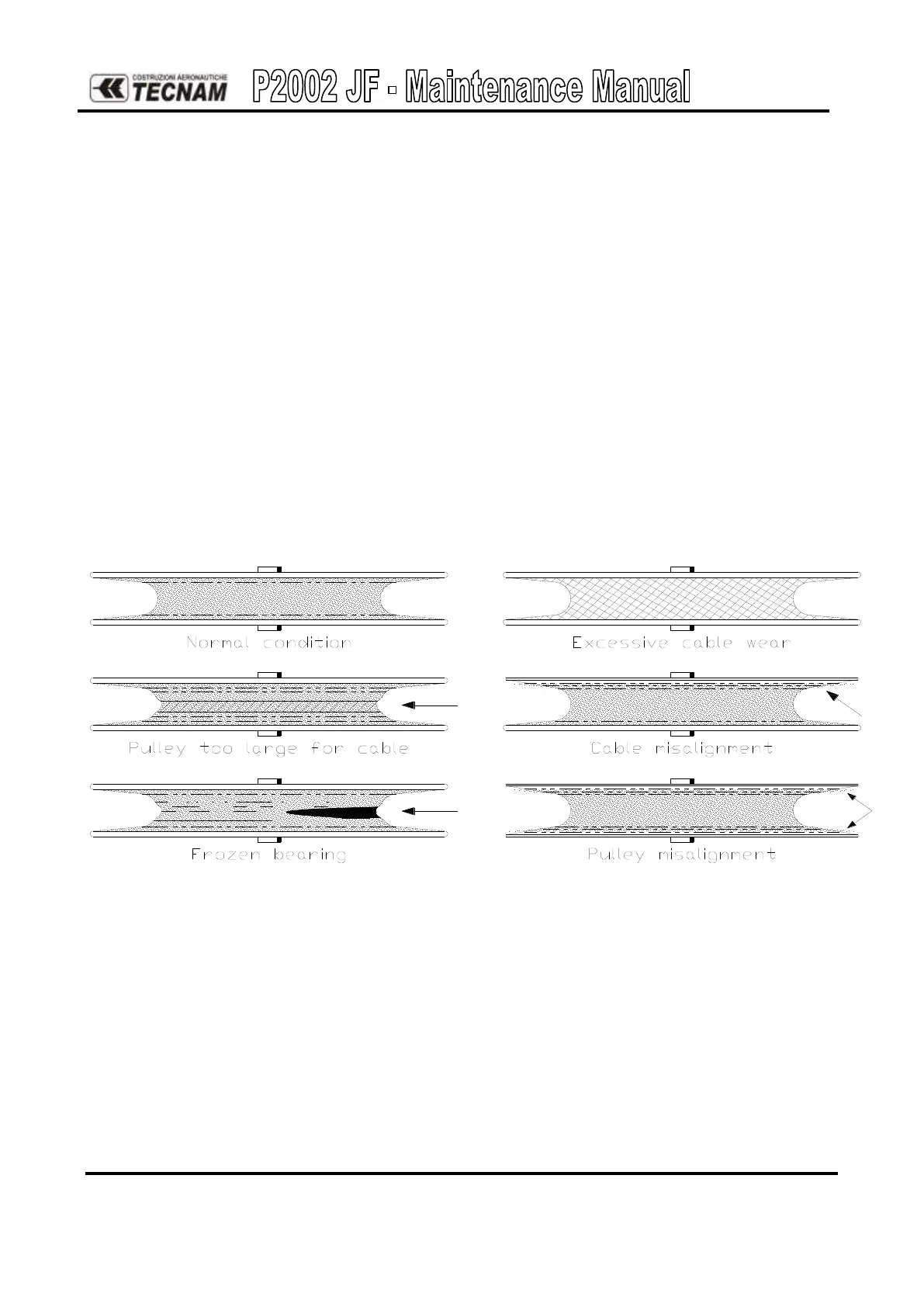

Pulley wear patterns

Various cable system malfunctions may be detected by analyzing pulley conditions. These

include such discrepancies as too much tension, misalignment, pulley bearing problems, and

size mismatches between cables and pulleys. Examples of these conditions are shown in the

figure below.

Figure 4. – Pulley wear patterns

Loading...

Loading...