Page 204 2

nd

Edition – Rev 0

32-40

NOSE LANDING GEAR – MAINTENANCE PRACTICES

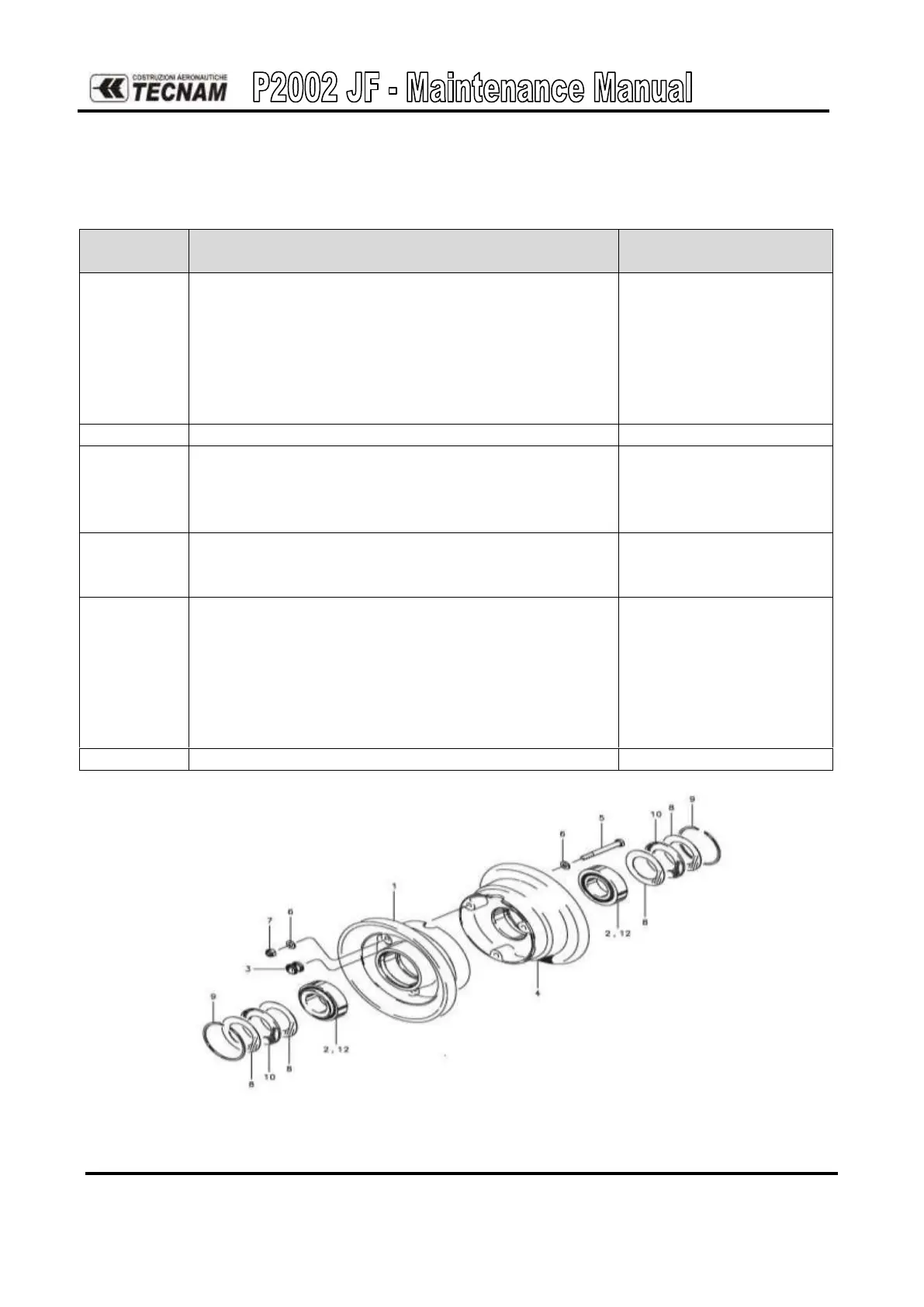

6. NOSE WHEEL REASSEMBLY

Procedure

NLG removal

Task description

Additional info &

References

Make sure the inside of the tyre is clean and dry.

Inflate the inner tube just enough to round it out.

Install the tyre and inner tube on outer wheel half,

inserting the valve stem through the valve hole in the

wheel. Place the inner wheel half inside the tyre. Align

the marks made at disassembly with those on the outer

wheel half.

Align both holes with wheel half.

install bolts (5) through wheel halves. Inspect bolts and

washers (6) prior to assembly (nuts are to be on valve

side of wheel). Torque nuts to value specified on wheel

nameplate.

If removed, carefully fit bearing cup (2). Fit bearing

cone (129, seals (8 and 10) and snap rings (9) into each

wheel half.

Inflate tyre to correct rated inflation pressure. Deflate

tyre to let tube adjust to proper position. Reinflate to

correct pressure and install valve stem locking nut.

Tyre will have to have pressure adjusted in 12 to 24

hours. Check carefully for leaks. When tyre is

correctly inflated and leak-free it can be installed on

aircraft.

restore hub-tyre slippage mark.

Figure 22. – Nose lanfing gear

Loading...

Loading...