TEEJET 5000 OPERATORS MANUAL SEED DRILL, SIMBA

5.65

TRAMLINE CONTROL

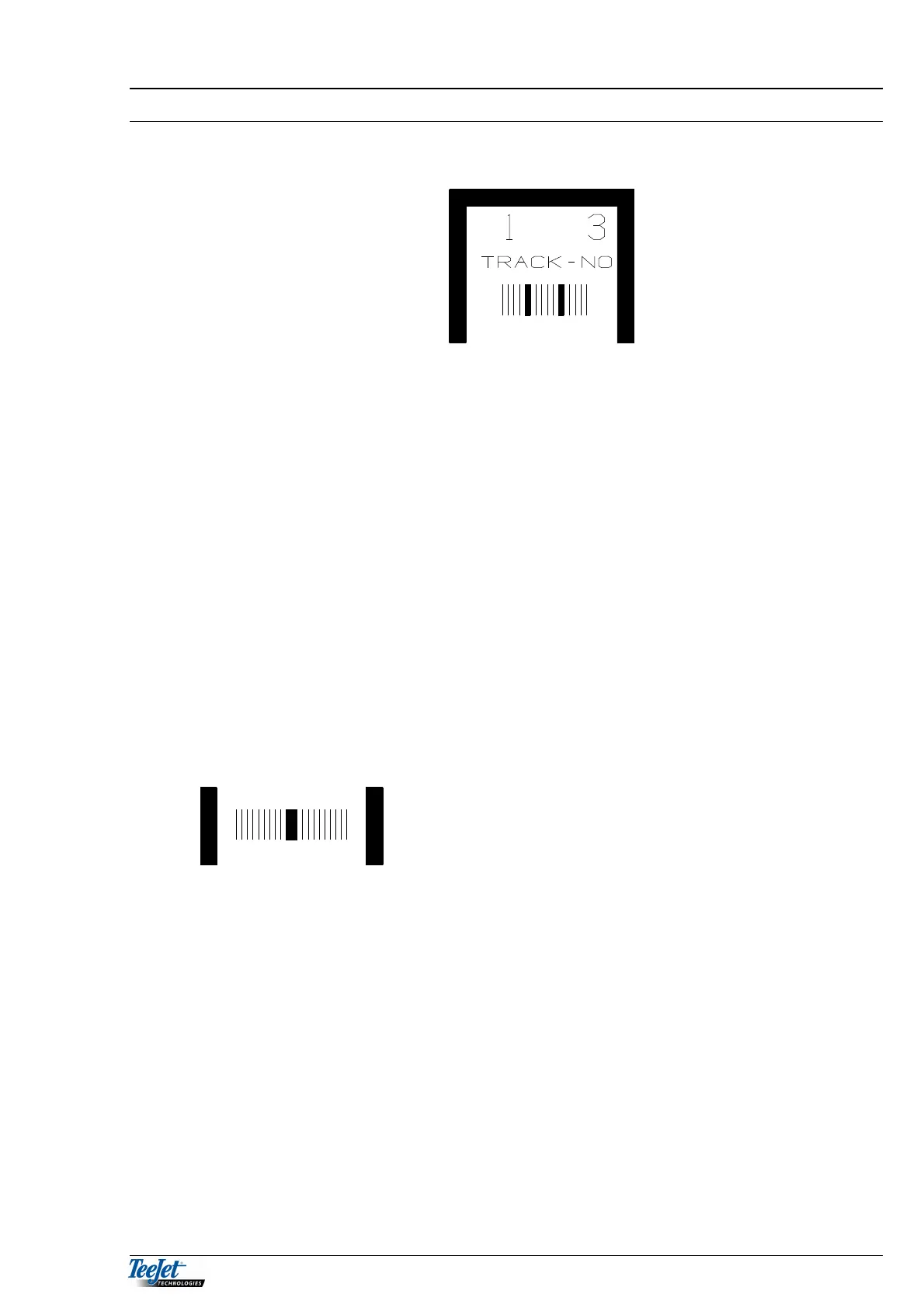

The primary function for seed drills is the track number. The following picture is

displayed:

Bout number Track number

The bout number is the present bout being driven in the field (counts 1 each time

the drill is lifted). The track number is what has been encoded (see “ENCODE”).

The TeeJet 5000 has 2 different methods of controlling the tramlines (A and B).

The method is selected under “ENCODE”:

METHOD A

This method is a new and logical method of making tramlines.

If the tramlines are to be made on uneven bouts (3,5,7, or 9) then the tramlines will

always be made in the middle bout. Two clutches are fitted to the middle of the

drill. See the drawing for METHOD A UNEVEN.

If the tramlines are to be made on even bouts (2,4,6, or 8), then the tramlines are

split between the 2 middle bouts. The field must be sown up and down as there is

only 1 clutch fitted on one side of the seed drill. See the drawing for METHOD A

EVEN.

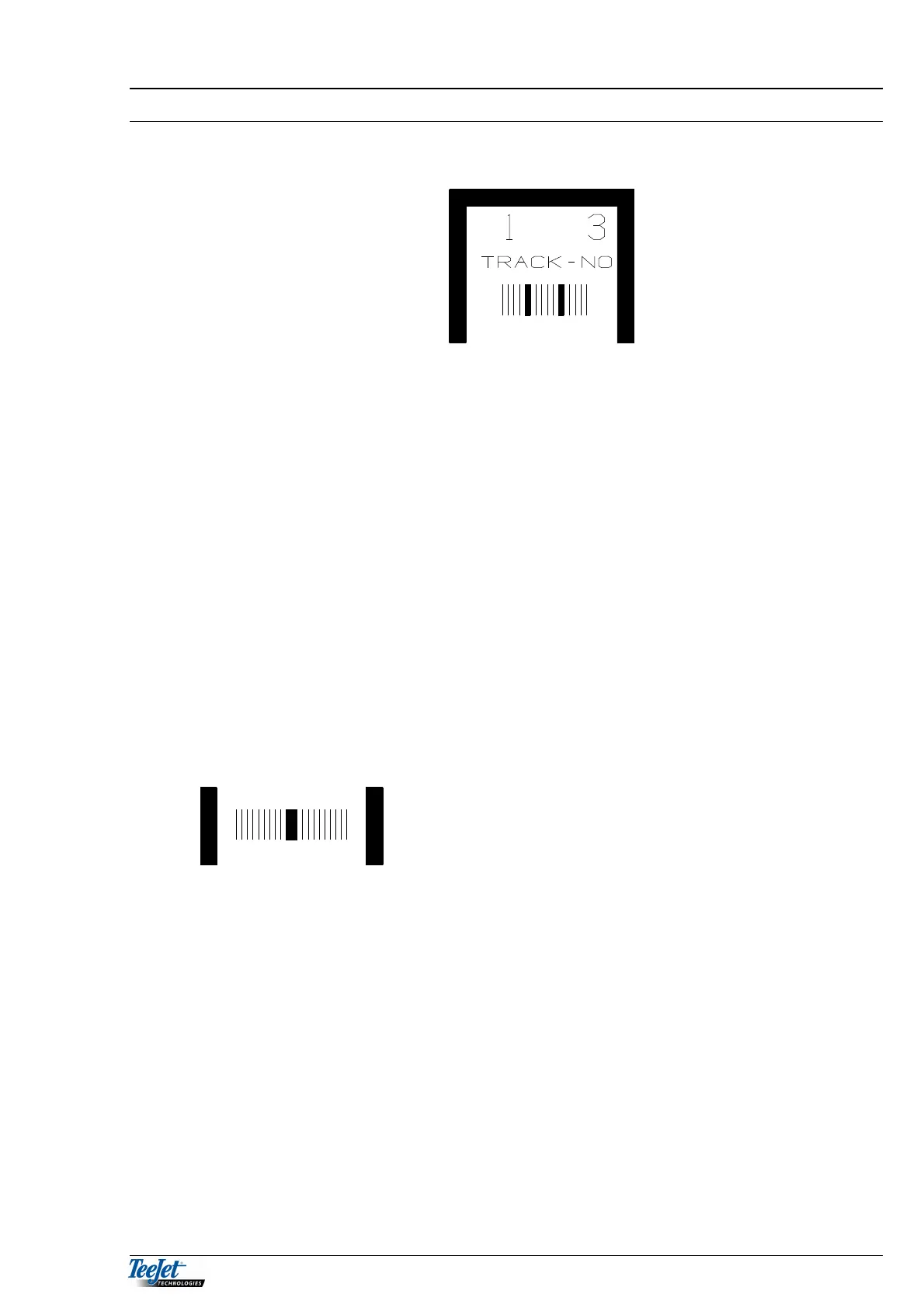

The tramlines are displayed for this method thus:

METHOD B

This method is older and better known. Tramlines are made when the present bout

is the same as the track number. The operator must know how the field has been

started.

If tramlining is required in on uneven bouts (3,5,7, or 9) the system works well.

Tramlines are made, using 2 clutches fitted in the middle of the seed drill, when

the present bout number is the same as the encoded track number. See the

drawing METHOD B UNEVEN.

If the tramlines are to be made on even bouts (2,4,6, or 8), then the operator must

drive around the field with only one half of the seed drill open. This is necessary,

as the tramlines cannot be split over 2 bouts. The clutches are fitted in the middle

of the seed drill, and the tramlines are made in one bout. See the drawing

METHOD B EVEN.

Loading...

Loading...