1132 HEIDENHAIN Technical Manual MANUALplus 620

Set the following parameter values to check the transition from straight line to

circle:

Record the following error s-diff and the jerk j-nom of the respective axes

with the integrated oscilloscope.

Turn the feed-rate potentiometer completely down.

Start the test program and turn the feed-rate potentiometer slowly and

carefully up until an acceptable following error (< few µm) is attained.

On the integrated oscilloscope, read the jerk j-nom at the transition from

straight line to circle of the respective axis.

Enter this jerk value in MP_axTransJerk.

For the adjustment of MP_axTransJerk described here it is essential to

consider only the geometric influences of the path (corner, transition from

straight line to circle etc.) The development of the feed rate is without effect.

In the table above, MP_minPathFeed is therefore set to a high value. A

reduction of the feed rate due to other criteria is thus prevented; the feed rate

stays constant during the measurement.

During roughing the jerk value can increase until the machine gets loud or the

following error s-diff becomes too large. For smooth surfaces during

roughing the corner jerk should barely limit the feed rate.

Reset the parameters to the original values when the check is finished!

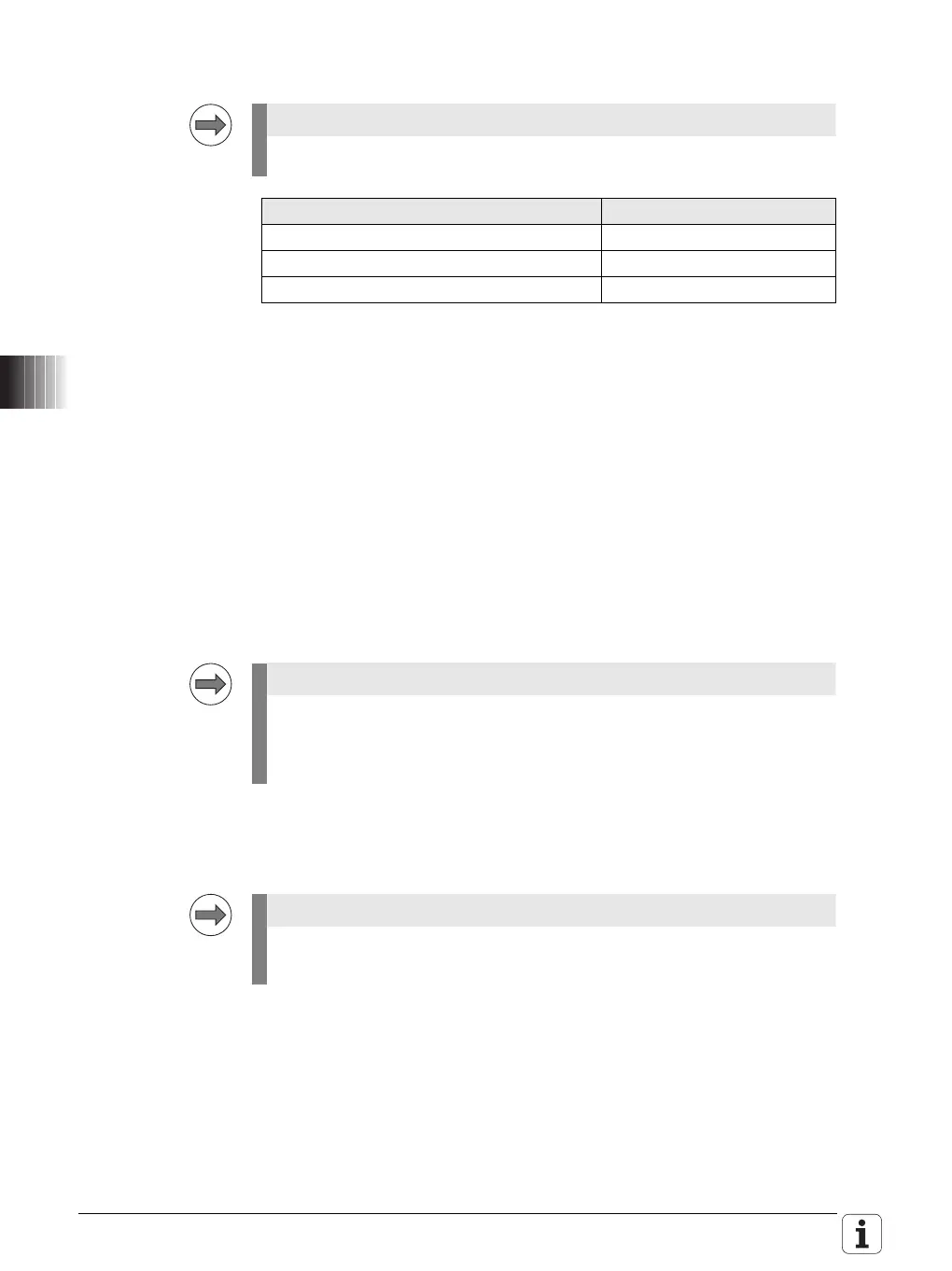

Machine parameters Recommended values

CfgLaPath: MP_minCornerFeed 0

CfgLaPath: MP_minPathFeed Very high

CfgLaAxis: MP_axTransJerk Very high

HEIDENHAIN recommends:

Always record the feed rate during the measurements to check whether it

remains constant.

For more information on the MP_axTransJerk and MP_axPathJerk

parameters, please also refer to "Axis-specific limit values" on page 831.

Loading...

Loading...