PCDU

SM 7-47 D0CA/D0C9/D0C8/D0CB

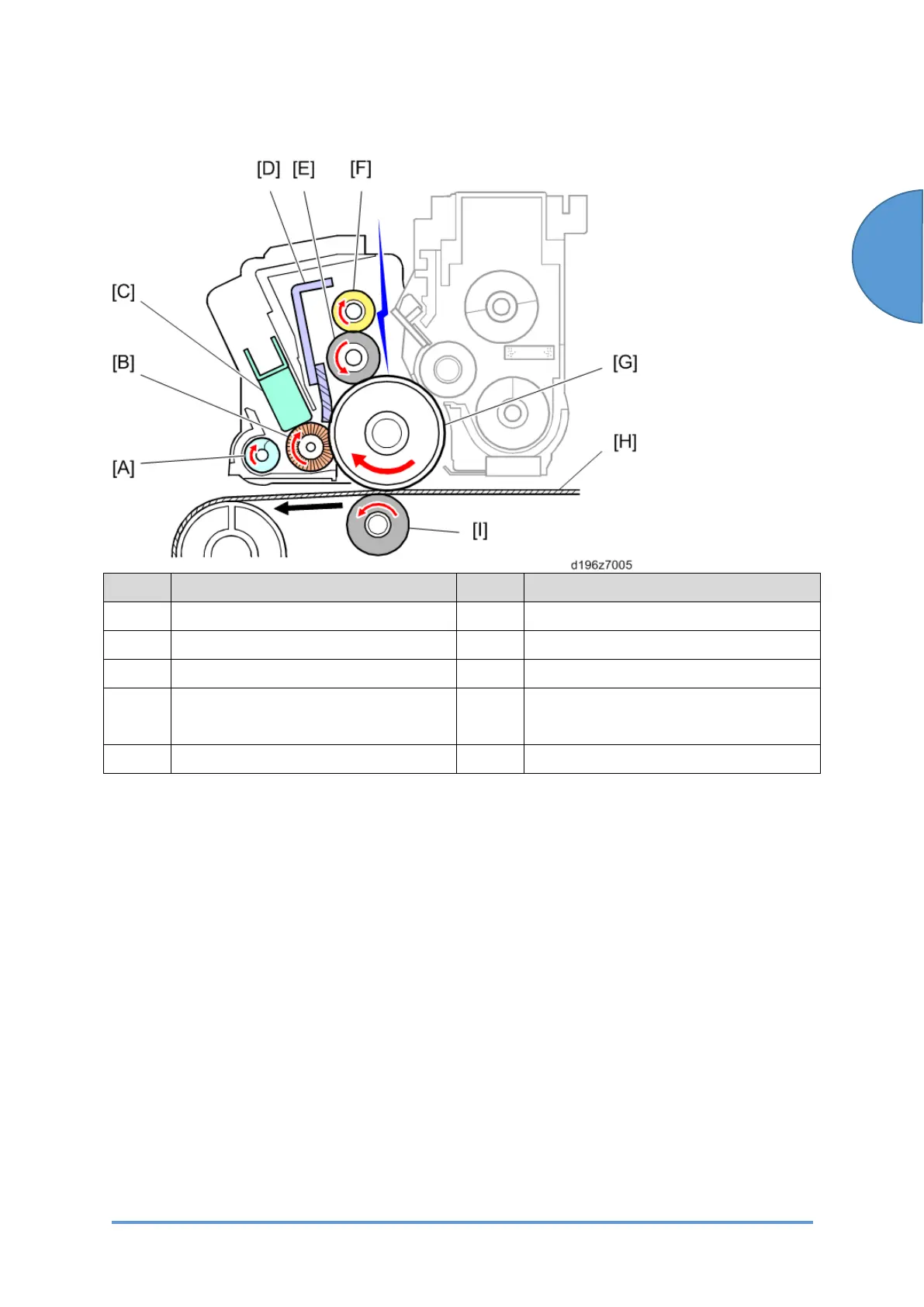

7.6.2 OPC DRUM

Callout Item Callout Item

[A] Waste Toner Transport Coil [F] Charge Roller Cleaning Roller

[B] Lubricant Brush roller [G] OPC Drum

[C] Lubricant [H] Image Transfer Belt (ITB)

[D] Drum Cleaning Blade (Counter

Rotation)

[I] Image Transfer Roller (1st Transfer

Roller)

[E] Charge Roller - -

A charge roller [E] charges the surface of the OPC drum [G] and drives the charge roller

cleaning roller [F].

This machine uses an organic photo conductor drum (OPC drum) [G] for image

creation.

The laser from the laser unit forms an electrostatic latent image on the OPC drum (exposure),

and the toner supplied from the developing unit adheres to the OPC drum (development). The

toner on the OPC drum is transferred to the image transfer belt [H].

The drum cleaning blade [D] is mounted in contact with the OPC drum [G] in a direction

opposite to the drum rotation, and scrapes off the toner.

OPC drum cleaning and lubricant application are done at the same time.

The lubricant is applied with the lubricant brush roller [B].

The lubricant brush roller [B] rotates in the opposite direction to the OPC drum [G].

Toner and foreign objects are removed from the edges of the blade by rotating the drum

counterclockwise when a copy job is done.

The waste toner collected by the drum cleaning blade [D] is transported to the front of the

machine by the waste toner transport coil [A] and deposited in the waste toner bottle.

Loading...

Loading...