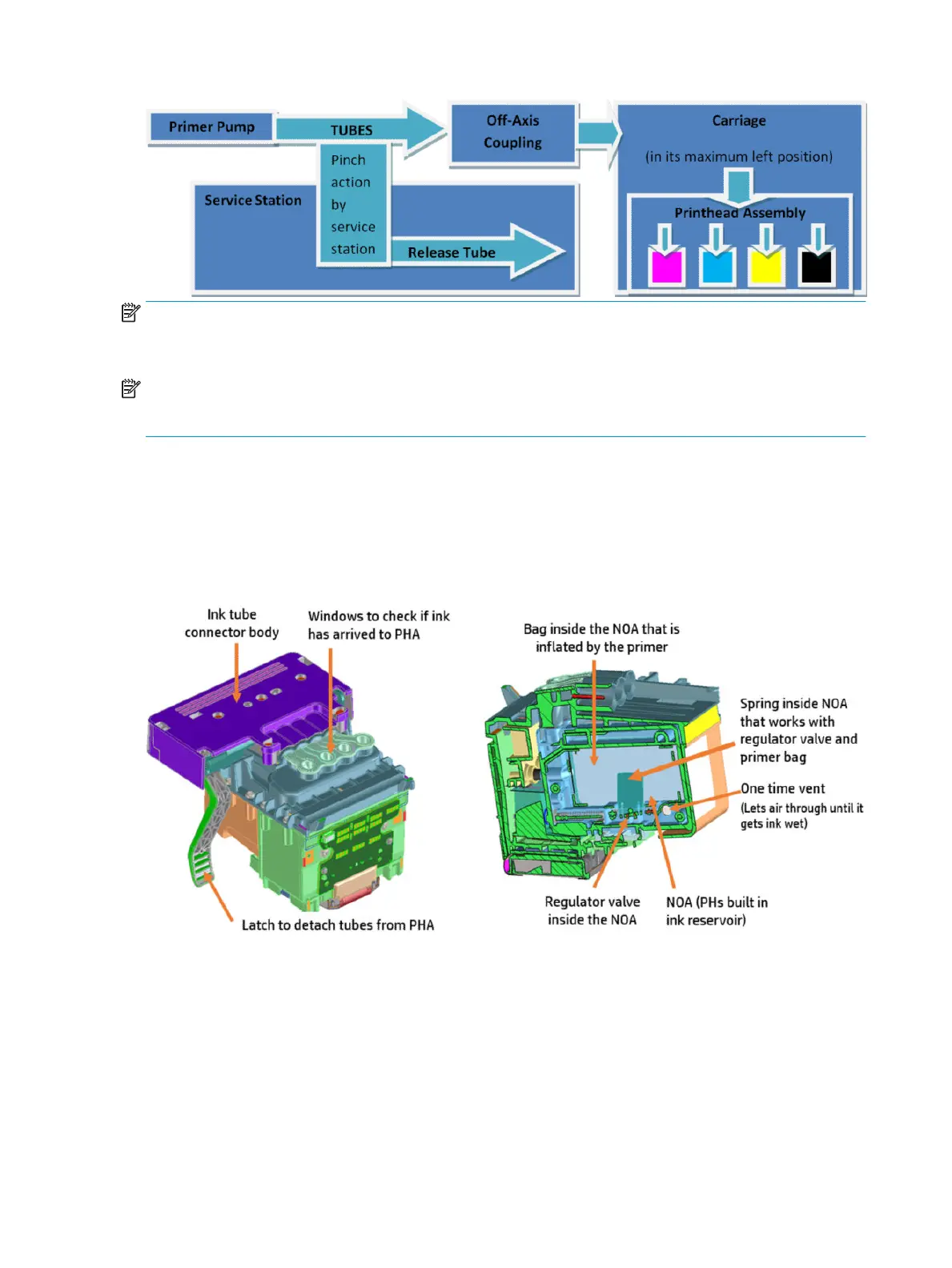

NOTE: There is no pressure sensor in the system. The Prime Pump operates at a certain time to reach a

specic pressure level, the system is depressurized by releasing the pinching of the release tube in the Service

Station (by moving the service station).

NOTE: It is important to ensure the Carriage reaches the maximum left position; if not, the o-axis coupling

will not connect the Prime Pump with the Carriage. Also, the coupling is made of a rubbery material,

degradation of the material will aect Primer performance due to air leaks.

Electronics

The control driver of the Prime Pump is located on the printer bundle board located on the right-hand side of

the printer. There is no encoder for the Prime Pump. This pump is managed only by a DC motor activated for a

certain period of time to create the required priming pressure.

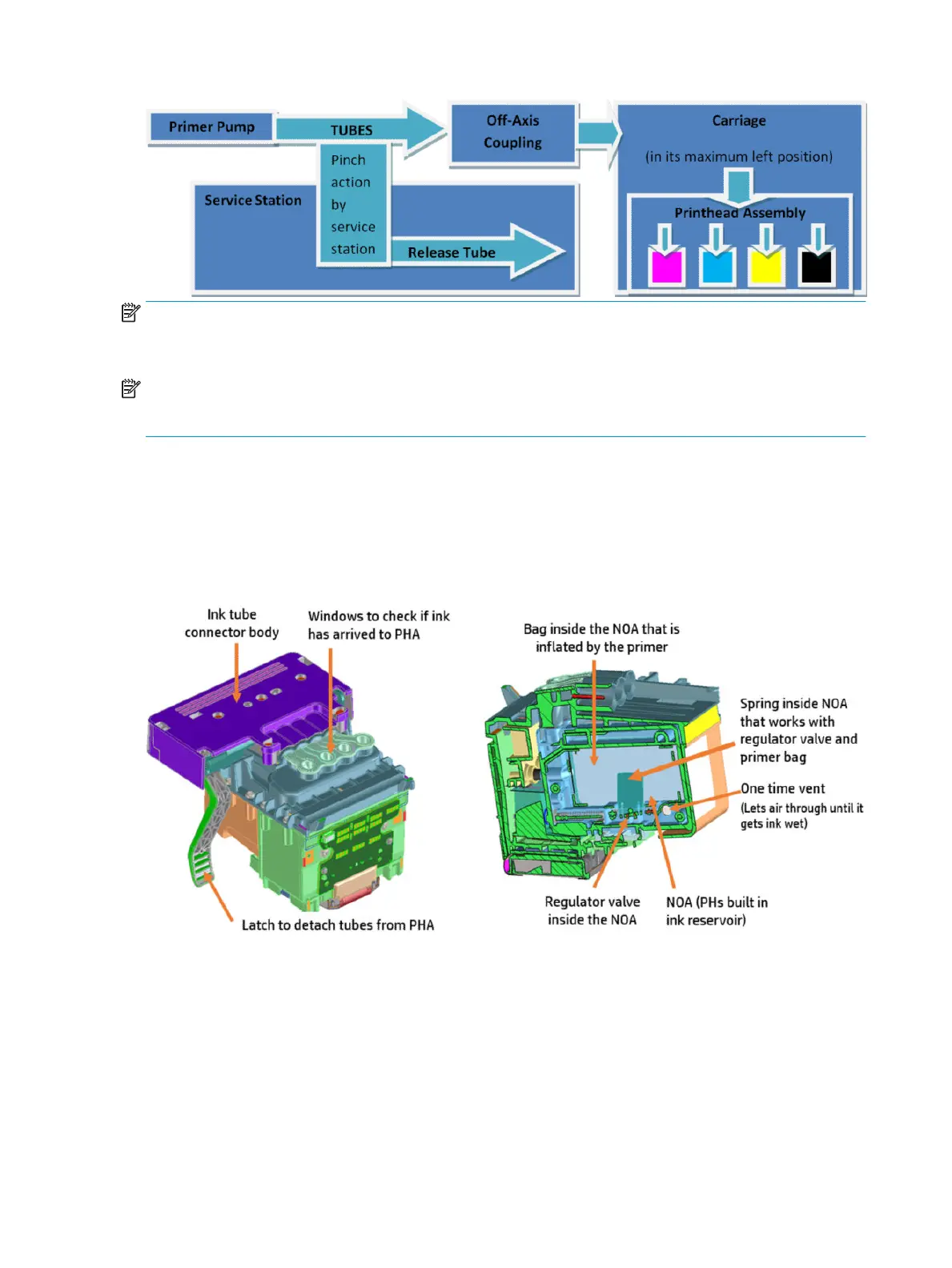

Printhead assembly

Notes and considerations

The printhead operates as a full assembly, regulating ink ow in the NOA regulator, and warehousing air

during the life of the PHA. This is done by balancing pressure between the inside of the NOA regulator and

atmosphere. When ink is printed out, the pressure becomes more negative inside the chamber, causing the

bag to open, which allows more ink into the system, putting it back into equilibrium and closing the regulator.

There are 4 colors on the die. With the PCA facing away from you, the color order is Black, Cyan, Magenta, and

Yellow.

12 Chapter 1 Printer fundamentals ENWW

Loading...

Loading...