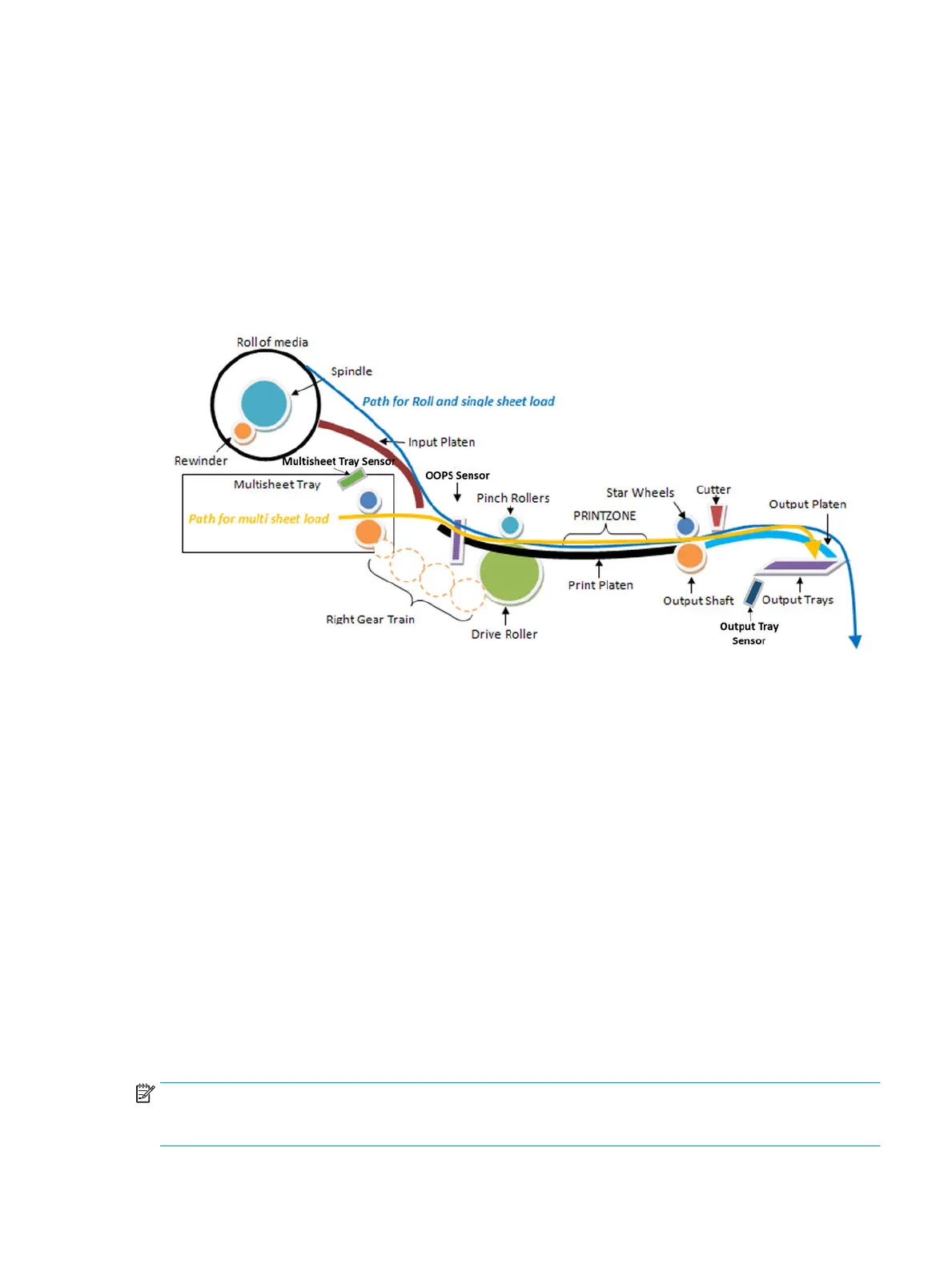

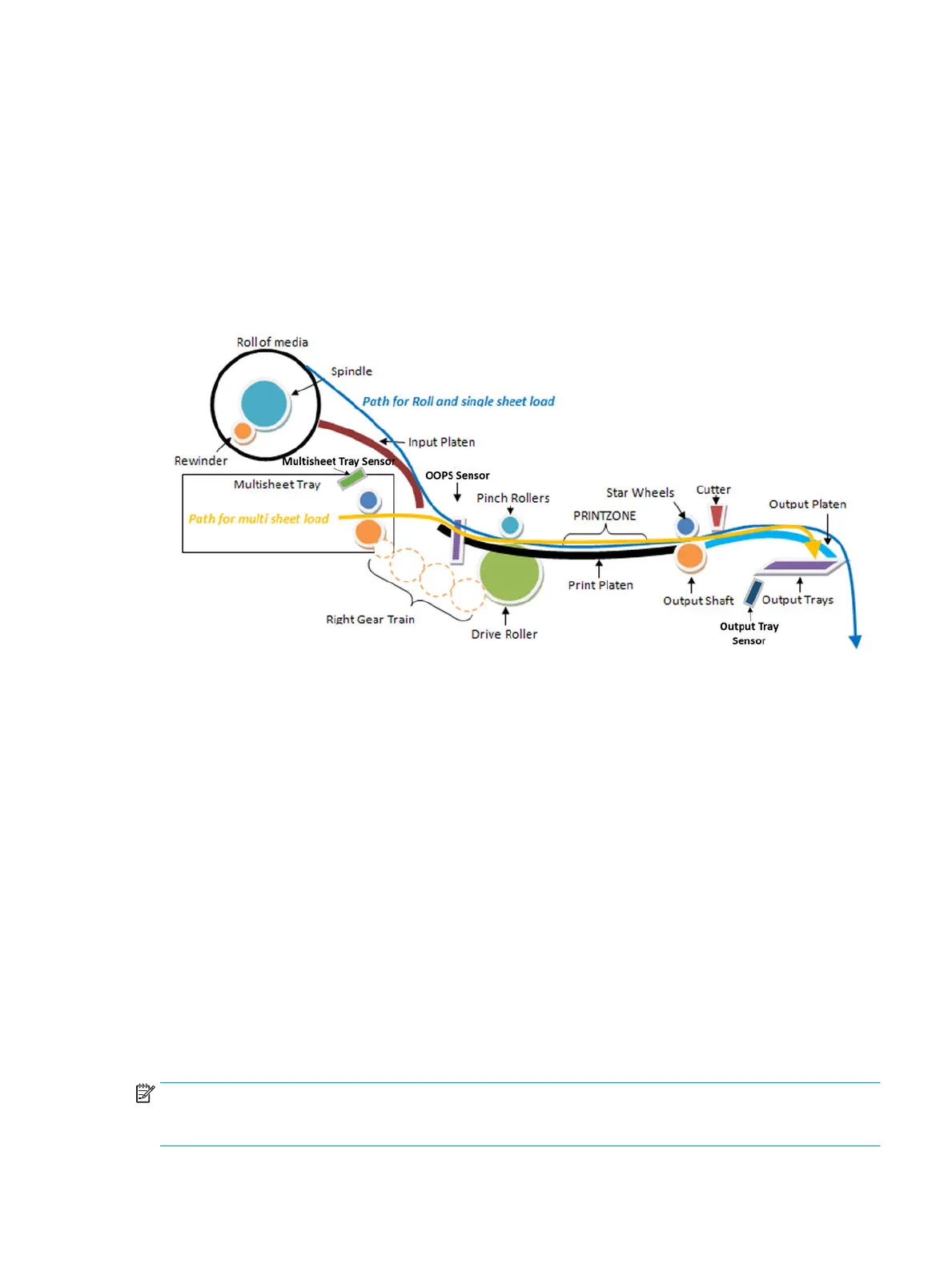

Paper can be loaded using a roll, which is mounted on the rear spindle, or single sheets loaded from the Multi-

Sheet Tray, or single sheets loaded singly.

The paper passes from its source (Roll, Single Tray, or Multi-Sheet Tray) until it touches the Out-Of-Paper

Sensor, when the printer detects the presence of the paper and proceeds to load it.

To perform the paper feed, the printer catches the paper in between the Drive Roller and the Pinch Rollers

(Pinch Rollers are spring-loaded pushing the paper down on top of the Drive Roller), then the paper is pushed

forwards on top of the Print Platen in the print zone, which is where the printing operation is performed. The

paper advance is provided by a motor that moves the Drive Roller. The exact position of the Drive Roller and

hence the paper is controlled by an Encoder Disk located on the roller axis.

The printed paper then passes between the Output Shaft and the Starwheels (which keep the paper tension

as at as possible for printing) to exit on the Output Platen, where it is held in case of cut sheet or is cut to fall

on the output basket in the case of roll paper.

The Output Shaft is designed to over-advance the Drive Roller movement slightly, and hence create the

necessary paper tension to keep the paper as at as possible. The Starwheels are spring-loaded and are

designed to create force on top of the paper, this is done so as to leave the paper unmarked and at the same

time allow the Output Shaft force to be appropriately transmitted.

In the Roll conguration, the rewinder module generates back force while printing to facilitate paper control.

A key electrical element of the paper path is the Paper Sensor (also known as the Out-Of-Paper Sensor or

OOPS). This sensor is located at the beginning of the Print Platen; it detects paper insertion for roll load and

single-sheet load.

Electronics

In the paper-path driving system, the only electrically active element is the Drive Roller. The Drive Roller is

impelled by the drive roller motor and it contains an Encoder Disk on the axis to determine its position. The

Encoder Disk is read by two sensors. One, the “encoder sensor”, designed to read the encoder, counts the

Encoder Disk (the Encoder Disk outer marks) and another one, the “encoder index sensor”, determines the

start position (the 0 position) of the Drive Roller by reading the inner thicker lines of the Encoder Disk.

NOTE: Every time the printer starts up, it searches for the 0 position of the Drive Roller. If this search fails

(which means that the index sensor is faulty), the printer will give a system error and will be unable to

initialize.

ENWW Subsystems 21

Loading...

Loading...