Label Description

Support menu: This can be used by customers under the

guidance of phone call agents assisting remotely. Using this

menu, customers can perform troubleshooting tasks and access

printer information.

From the Home screen, press the following icons one after the

other: , , , .

If there is a system error, you may not be able to reach the home

screen. In this case, press the Power button and hold it down for

15 seconds.

Extended Support menu: Service engineers only From the Home screen, press the following icons one after the

other: , , , .

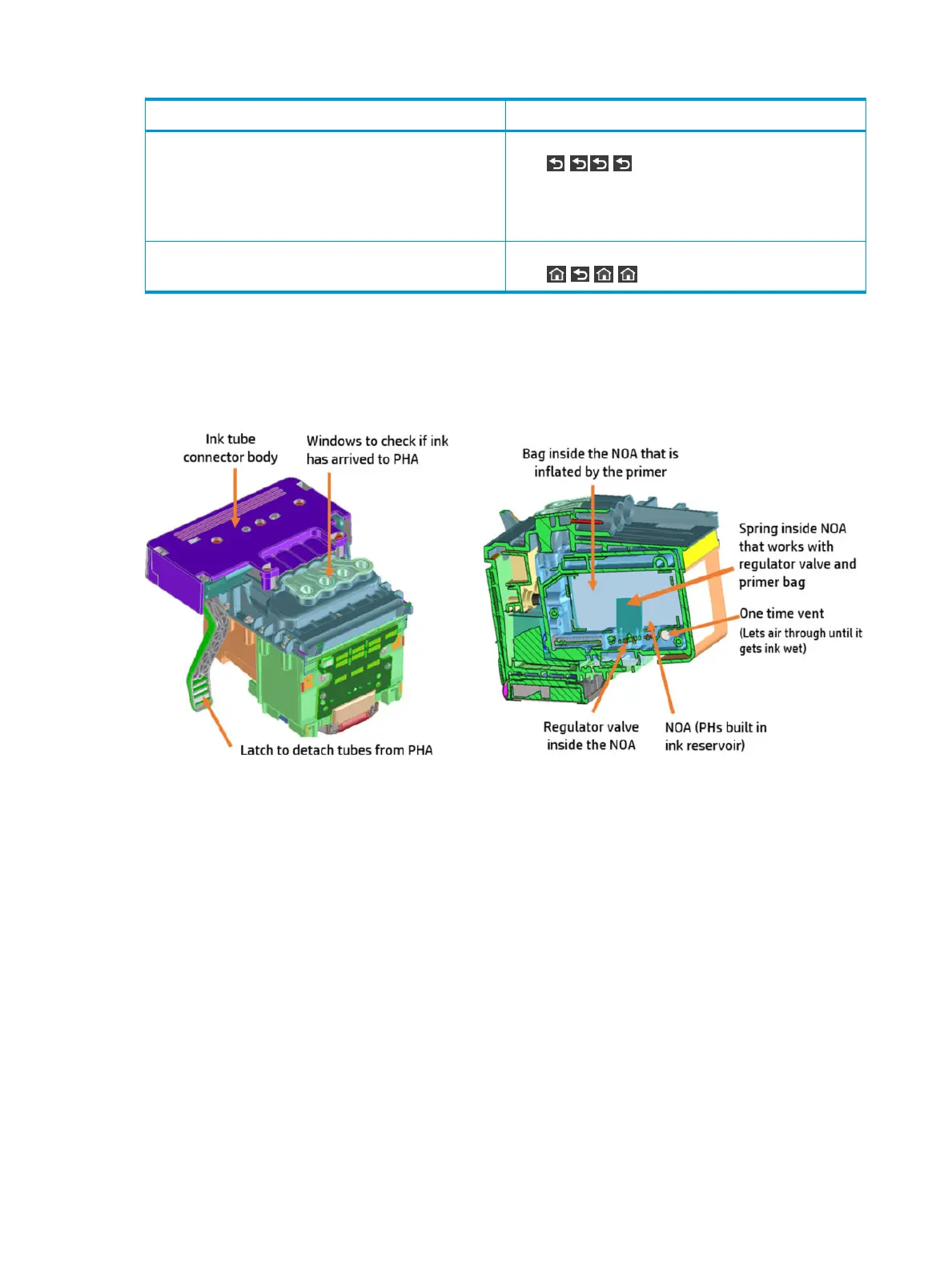

Start up process - preparing the ink system for the rst time

The printer tubes and PHA are shipped dry. To ready them to print, they must be lled with ink, and need

servicing to make the nozzles wet, and manage air within the PHA.

Three subsystems are primarily involved in this process: the ink supply station, the primer, and the service

station.

●

The ink supply station pumps ink from the supplies, through the tubes, to the PHA.

●

The primer opens the PHA regulator to allow ink to enter the PHA. It also manages the air within the

PHA, moving any air bubbles to the upper part of the PHA reservoirs (also known as NOAs).

●

The service station cleans the PHA nozzles after the process, readying the PHA for the rst print.

The process ow is as follows:

1. The primer activates to inate the bag inside the printhead so that the regulator is open during start-up.

The primer air circuit holds the regulator open during the start-up ink ll process.

2. Once the regulator is open, the ink supply station starts pumping to push ink through the tubes. The rst

ink is used to ll up the empty tubes. The air in the tubes is purged out of the one-time vent in the PHA.

3. Once the tubes are lled, ink lls the NOA to the one-time vent. Air continues to purge out of the vent.

When the ink reaches the one-time vent, it becomes wet and the air in the PHA remains. Extra ink is sent

4 Chapter 1 Printer fundamentals ENWW

Loading...

Loading...