13 - 2

IPN 074-397-P1G

HAPSITE Smart Operating Manual

13.1.1 How the HSS Operates

The functions of the HSS are to provide consistent partition of analytes between

the sample and the headspace, and to transfer a representative sample of the

headspace to the HAPSITE for analysis.

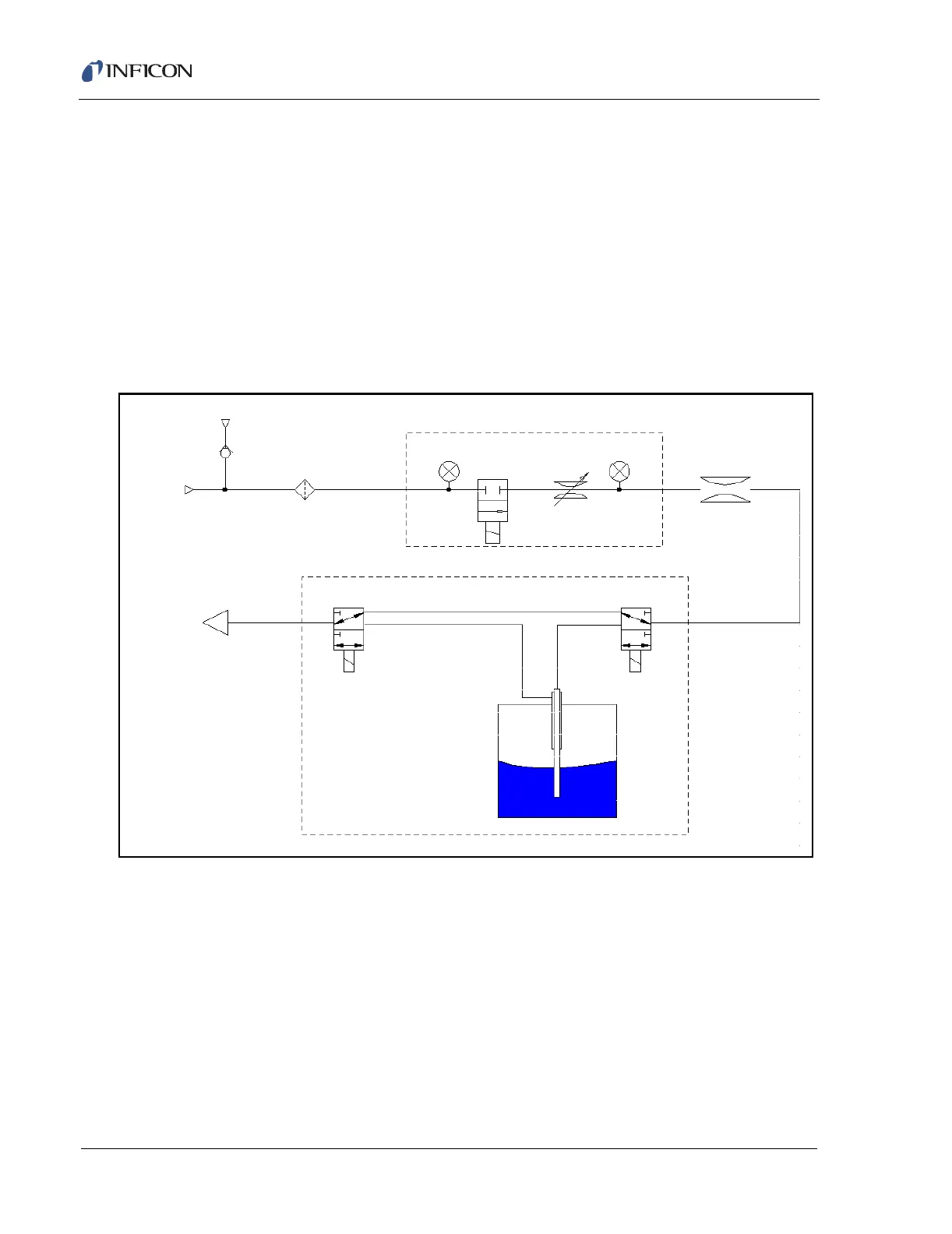

Figure 13-2 is a schematic of the gas flow system which accomplishes these

functions. The flow starts with the nitrogen supply, at the upper left. This can be

from disposable canisters or from an external cylinder supply. The nitrogen

pressure and flow are controlled by two pressure gauges, a shut-off valve, the

Variable Orifice valve and a fixed restrictor. All the valves in this system are

operated under software control.

Figure 13-2 HSS Operation Flow Diagram

Two three-way valves direct the flow to either bypass the vial (in the position

shown) or purge through the vial. While a sample is being transferred to the

HAPSITE, the flow is directed through the long needle, below the surface of the

sample. The nitrogen flow into the vial is approximately balanced by the

HAPSITE’s sample pump flow out of the vial. The headspace sample is transferred

to the HAPSITE while maintaining neutral pressure in the vial.

At the end of the analysis, if a Purge cycle is programmed, the operator is prompted

to insert the needles into a clean vial and acknowledge by pressing RUN. Purge is

achieved by providing a flow of clean nitrogen through the needles, heated line and

sample loop in the HAPSITE, removing residual organics and moisture from the

N2 Canister

External Supply

Carbon Filter

HAPSITE

Transfer

Line

Supply Pressure

Control Pressure

VSO Valve

VSO PCB

Fixed Restrictor

Headspace Oven

Loading...

Loading...