05/2014

3-5

DC SC2020

Image Quality Troubleshooting

3.2 Image Quality Troubleshooting

Version 1.1

How to use the image quality troubleshooting (IOT/IIT/DADF)

Perform the following procedure to check the fault sample that is obtained during visit or the one that is

provided by the customer and proceed with the appropriate FIP.

1. If the defected sample is determined as the same problem with the one covered in this chapter

("Defect Image Sample") through visual observation, check the part which is causing the poor

image quality.

2. When the problem cannot be determined or there was no corresponding NG sample in 1 above,

proceed to the corresponding FIP below to repair the problem.

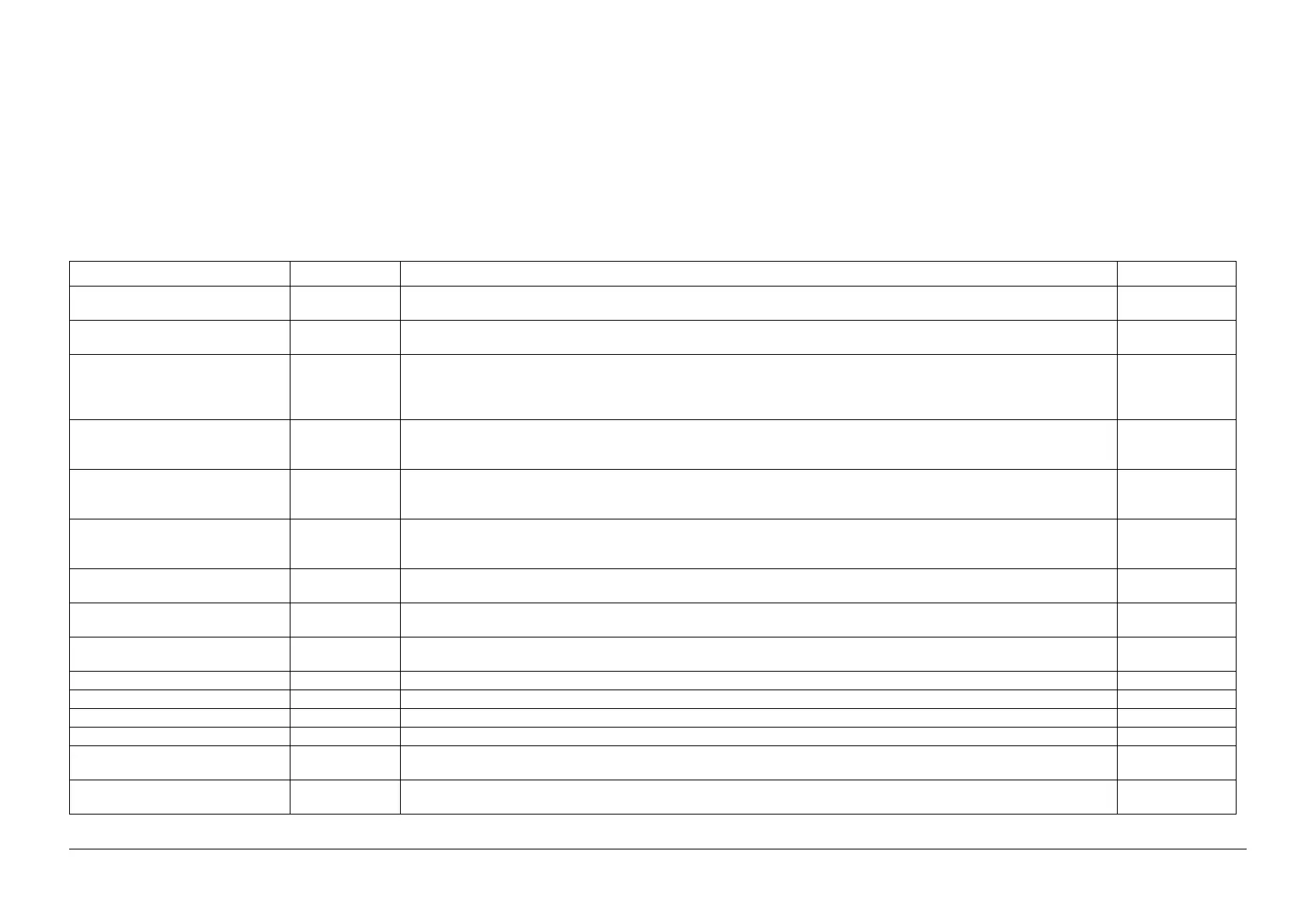

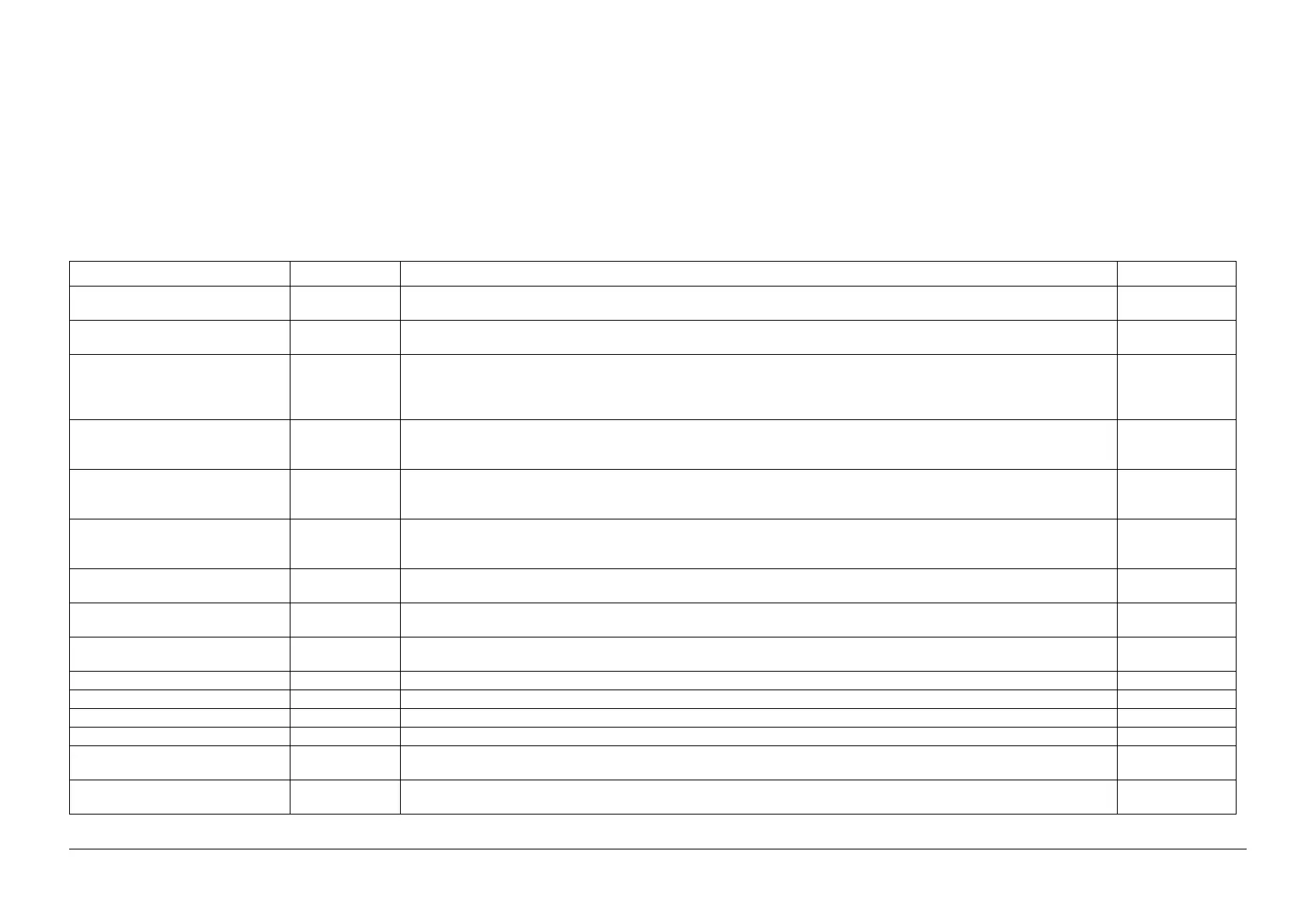

Table 1

Image Quality Problem SUB Symptoms Reference RAP No.

LPH Periodical Line LPH A line appears periodically as a result of the decrease in light quantity of the light emitter (chip) or from unevenness continuously

occurring in multiple chips.

IQ-1

Reverse DarkLines Transfer Phenomenon of part of the solid patch of K-color having patial darklines (multiple) at the FS direction.

Transfer defect occurred due to lack of electric charge in the toner before the secondary transfer.

IQ-2

Caterpillar Mark Transfer Removal of electricity with diselectrification material is performed in the charged state after the paper discharges the secondary

transfer part.

If the adhesion of the toner to the paper is weak and the amount of electricity removal is big, the toner image scatters and a round

shaped pattern appears continuously in the vertical direction.

IQ-3

Scalelike defect Transfer Removal of electricity with diselectrification material is performed in the charged state after the paper discharges the secondary

transfer part.If the adhesion of the toner to the paper is weak and the amount of electricity removal is big, the toner image scatters

and a semicircle shaped pattern appears.

IQ-4

Heavyweight paper image bleeding Transfer The rear edge of the paper gets flipped-up and moves closer to the center transfer belt after going though the Reg Shoot, and part

of the axial direction (around 25mm from the rear edge of the heavyweight paper) may get blurred from the electrical discharge

that occurs in the secondary transfer pre nip part.

IQ-5

Line color of photo receptor pitch

(94mm)

XERO/CLN Vibrations during the Drum CRU transportation may cause scrapes and friction in the BCR and the Photoreceptor, resulting in left-

over electrostatic memory on the Photoreceptor, which generates thin white streaks in the FS direction on the highlight portion at

the Photoreceptor Pitch.

IQ-6

BCR pitch (37mm) density uneven-

ness

XERO Charging failure occurs in weak contact parts which lowers the surface potential and the density of the half-tone image darkens

with a BCR pitch (37.7mm).

IQ-7

DarkLines (Fill speed/Half speed) XERO A faulty stripe along the rotational axis caused by an erroneous electrical discharge between the bias charge roller (BCR) and pho-

toconductor drum.

IQ-8

Toner color line DEVE It’s a vertical long thin line and the length may differ from couple mm to 10cm or longer. This occurs in solid or HT and does not

generally occur in the background part.

IQ-9

Thin line interruption Process Control Depending on the structure of the line, the interruption may stand out by the position of the screen. IQ-10

Moire Screen Depending on the document drawing pattern structure, Moire may stand out by interfering with the screen IQ-11

Diagonal line fluctuation IIT "Diagonal line fluctuation" occurs due to speed change of the read unit. IQ-21

Fogging around high density patch part IIT "Fogging around high density patch part" occurs due to the cavity performance of the CIS device. IQ-22

Vertical line due to lack of pixels

between CIS chips

IIT The "vertical line" may appear approximately every 18.3mm. IQ-23

Image quality difference during PLT/

DADF read

IIT/DADF DADF job tends to be out of focus than during platen job. IQ-24

Loading...

Loading...