05/2014

1-7

DC SC2020

Service Call Procedure

1.5 Periodic Replacement Parts/Consumables List

Version 1.1

1.5 Periodic Replacement Parts/Consumables List

When servicing, check the number of copies and number of fed sheets for the consumables and parts

that require periodical cleaning/replacement. Clean or replace them if necessary. For the history, enter

CE Mode and go to Printer Diag > Parameter > Life Print to check the coressponding counters (6.4.12.2

Life Print).

For the items that cannot be checked in CE Mode, clean or replace them according to the replacement

intervals (standard PV).

CAUTION

Do not place the imaging materials, such as the Toner and the Drum, in the car for a long time.

NOTE: Clean the Platen Glass with a Platen Wax Cleaner 499D 00194 (194D) every 10K Feeds.

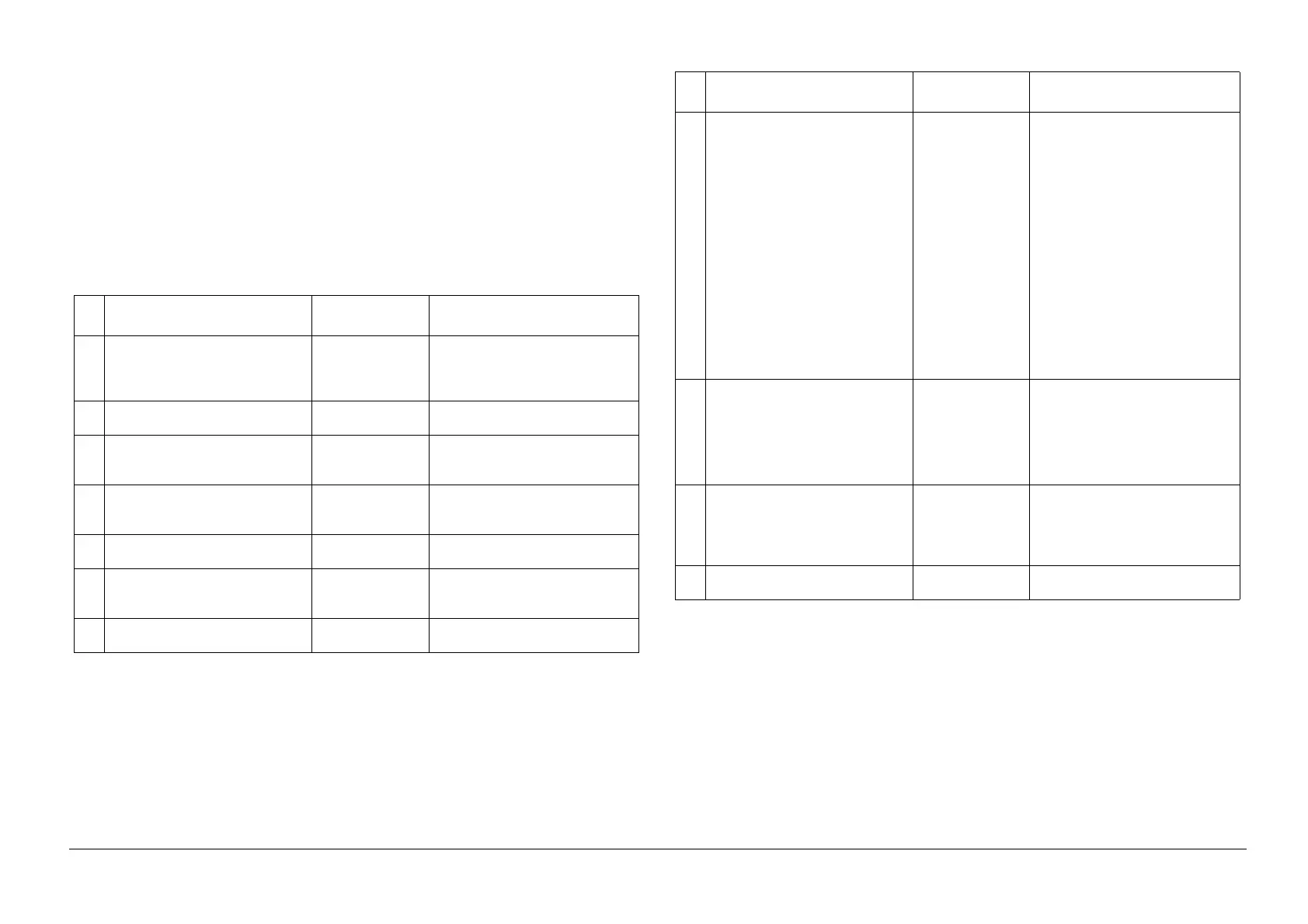

Table 1

No Parts/Consumables Name/PL No.

Replacement

Interval Description

1 Fusing Unit

(PL 7.1)

100KPV or IOT

resistance welding

time of

18,000,000sec

100KPV is calculated with A4L

100%.

2 Tray 1 Feed Roll / Retard Pad

(PL 9.2)

50KFeed 1 Feed = 1 Count Up.

Replace both at the same time.

3 MSI Feed Roll/MSI Nudger Roll/MSI

Retard Pad

(PL 13.3)

50KFeed 1 Feed = 1 Count Up.

Replace all 3 at the same time.

4 Tray 2 Feed Roll/Nudger Roll/Retard

Pad

(PL 10.3)

300KFeed 1 Feed = 1 Count Up.

5 Tray 2 Retard Pad

(PL 10.3)

50KFeed 1 Feed = 1 Count Up.

6 IBT Belt Unit (Includes IBT Belt

Cleaner)

(PL 6.1)

120KPV 120KPV is calculated with A4L

100%.

7 2nd BTR Roll

(PL 6.1)

120KPV 120KPV is calculated with A4L

100%.

8 Deve Unit

(PL 5.1)

38KPV 38KPV is calculated with A4L 100%.

Life Evaluation Condition: The stan-

dard life level (PV) is shown under

the following conditions since it dif-

fers according to the number of

Power On/Off, adjustments to main-

tain print quality, specification envi-

ronment, etc.

B-Zone environment, AMPV=4KPV,

Job size=2, AC=5%, YMCK: Each

color 5%

[GCO] Do not stop when life span is

reached.

[Other] Stop at Dead End (50KPV).

Switching possible in NVM setting.

Default is Stop. Notify with warning

before development life is reached.

9 DADF Feed Roll/Nudger Roll

(PL 56.5)

DADF Retard Pad

(PL 56.13)

200KPV Count up 1 with 1 Document Feed

Replace the Feed Roll, Nudger Roll,

and Retard Pad at the same time.

NOTE: Clean the Platen Glass with a

Platen Wax Cleaner 499D 00914

(194D) every 10K Feeds.

10 Drum Cartridge

(PL 8.1)

BW 89.6KPV equiv-

alent (700K Cycle)

FC 68.2KPV equiv-

alent (700K Cycle)

Configuration similar to CRU (The

worker basically is an engineer but

can request work to the user. Drivers

available. Instructions included).

Drum Cartridge for APO is CRU.

11 Odor Filter

(PL 19.1)

120KPV Individual support kit.

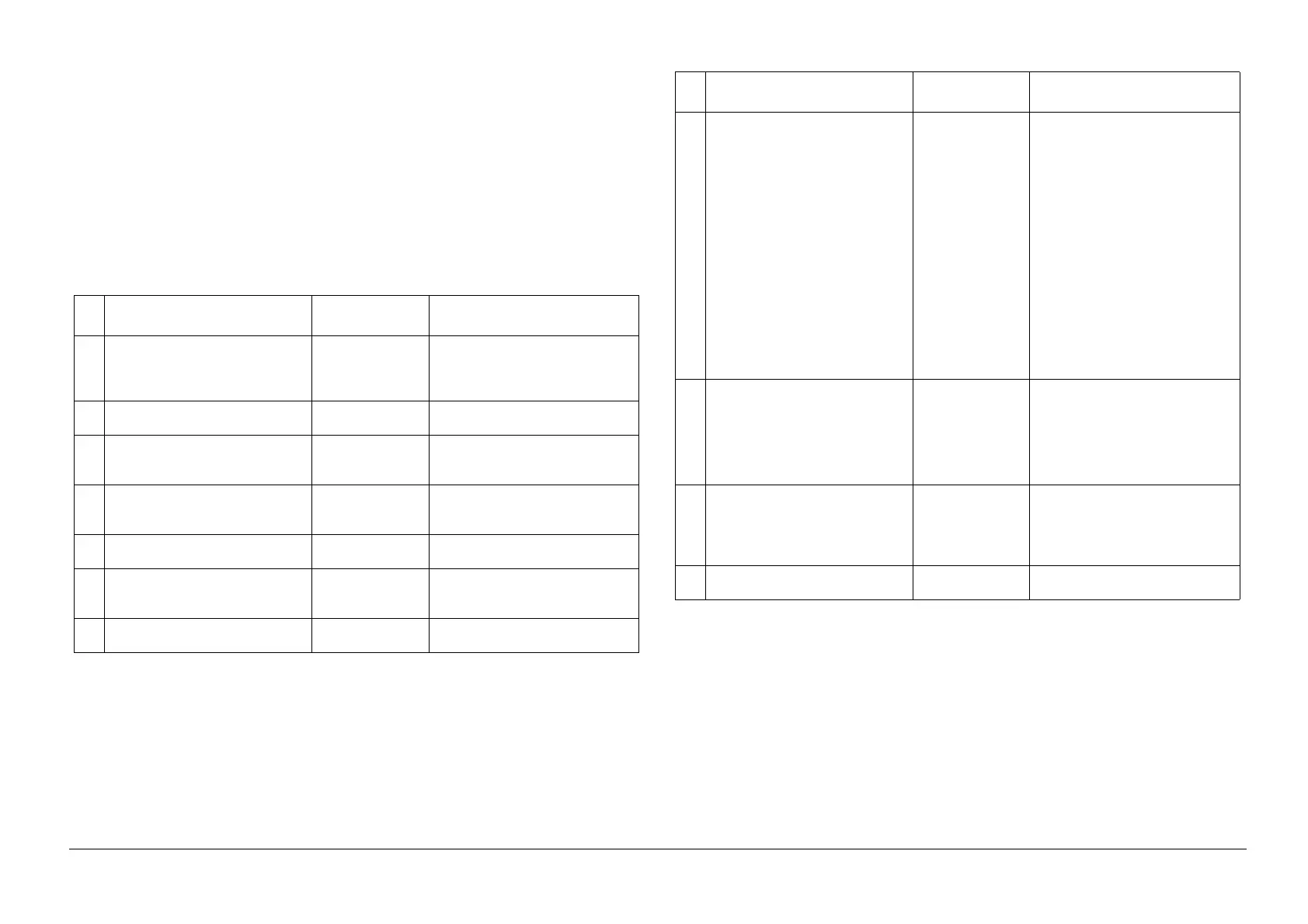

Table 1

No Parts/Consumables Name/PL No.

Replacement

Interval Description

Loading...

Loading...