05/2014

3-8

DC SC2020

3.2.1 How to use the image quality troubleshooting (IOT/IIT/DADF)

Version 1.1

Image Quality Troubleshooting

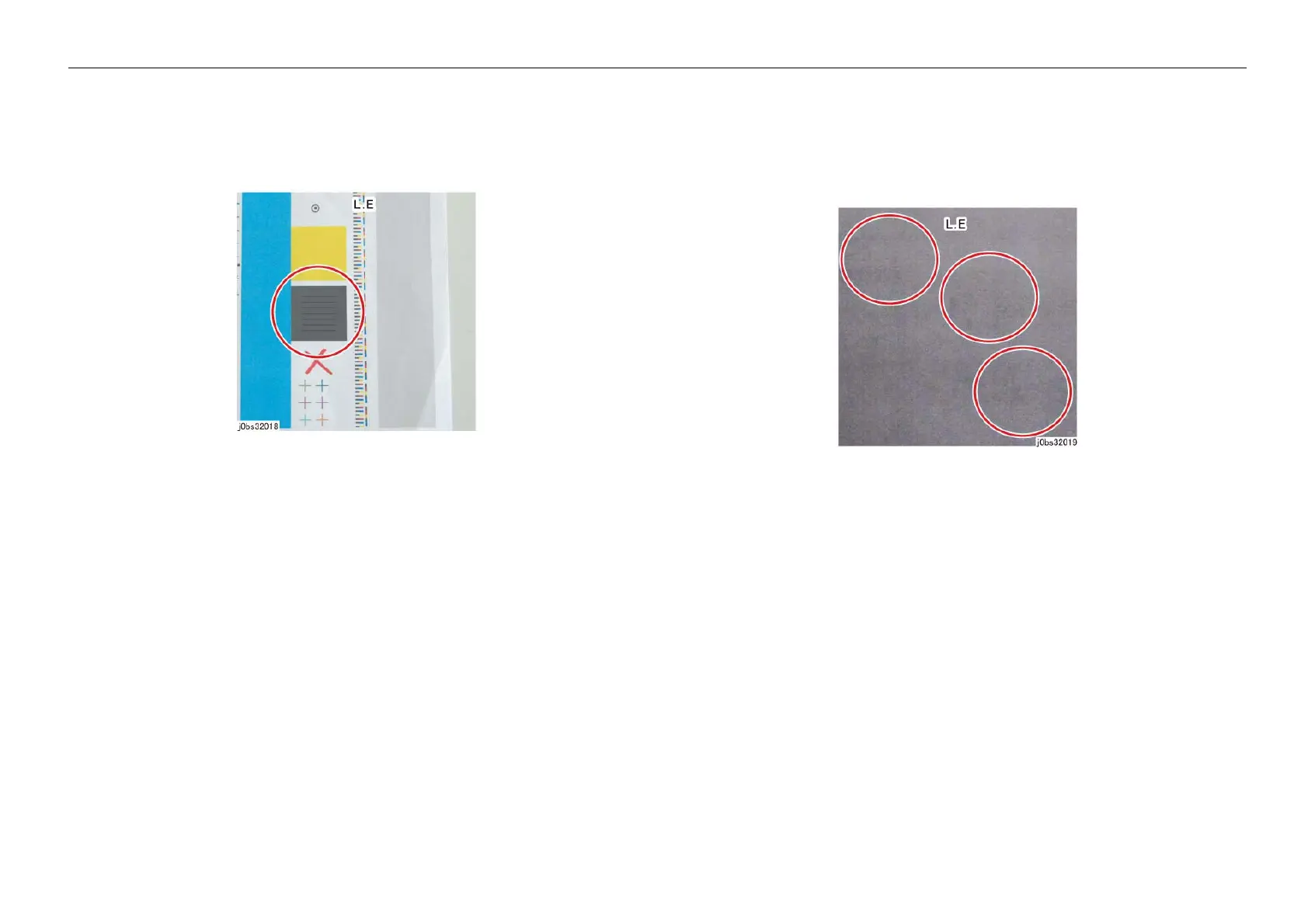

IQ-2 Reverse DarkLines

Part of the K color solid patch and a phenomenon that partly becomes a thick line (multiple) in the FS

direction

Transfer defect occurred due to lack of electric charge in the toner before the secondary transfer.

Figure 1 j0rk32018

[Cause]

Occurs when the develop ability drops, the density of solid patch decreases and Vdeve becomes large.

[Procedure]

Take a sample from an image that includes solid patch such as Total Chart and check by comparing with

image sample.

[Corrective action]

1. 2nd Transfer Voltage Offset Adjustment

• Optimize the secondary transfer voltage from [Tools -> Admin Settings -> Maintenance ->

Adjust 2nd BTR]. (Set to the Minus side.)

2. 1st Transfer Voltage Offset Adjustment

• Optimize the primary transfer voltage from [Tools -> Admin Settings -> Maintenance -> Trans-

fer Belt Unit]. (Set to the Plus side.)

3. TC Up

4. Vh Up

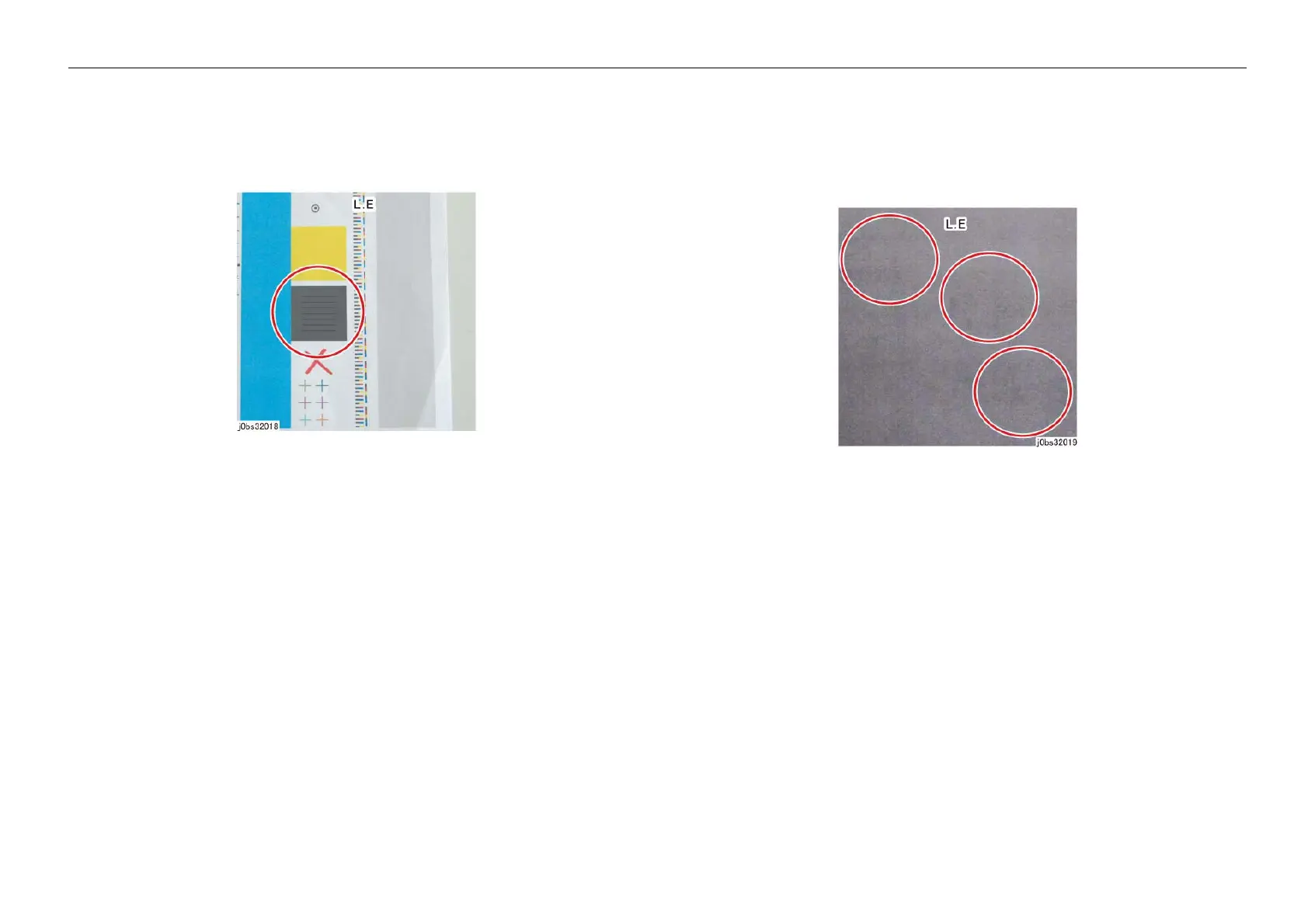

IQ-3 Caterpillar Mark (Transfer)

Removal of electricity with diselectrification material is performed in the charged state after the paper dis-

charges the secondary transfer part.

If the adhesion of the toner to the paper is weak and the amount of electricity removal is big, the toner

image scatters and a round shaped pattern appears continuously in the vertical direction.

Figure 1 j0bs32019

[Cause]

This is caused by low electric charge in the toner.

Stress Conditions:

• Plain paper (Lightweight paper)

• Mid humidity~High temperature environment

• Occurs in both Side1/Side2.

[Procedure]

1. Take a sample from a half-tone image with uniformed entire surface and check by comparing with

image sample.

2. Judge as this phenomenon if it is solved or improved by raising the secondary transfer voltage.

[Corrective action]

1. 2nd Transfer Voltage Offset Adjustment

• Optimize the secondary transfer voltage from [Tools -> Admin Settings -> Maintenance ->

Adjust 2nd BTR]. (Set to the Plus side.)

Loading...

Loading...