05/2014

3-31

DC SC2020

Image Quality Troubleshooting

3.2.2 How to use the image quality troubleshooting (IPS)

Version 1.1

3.2.5 Image Quality Limit Precaution

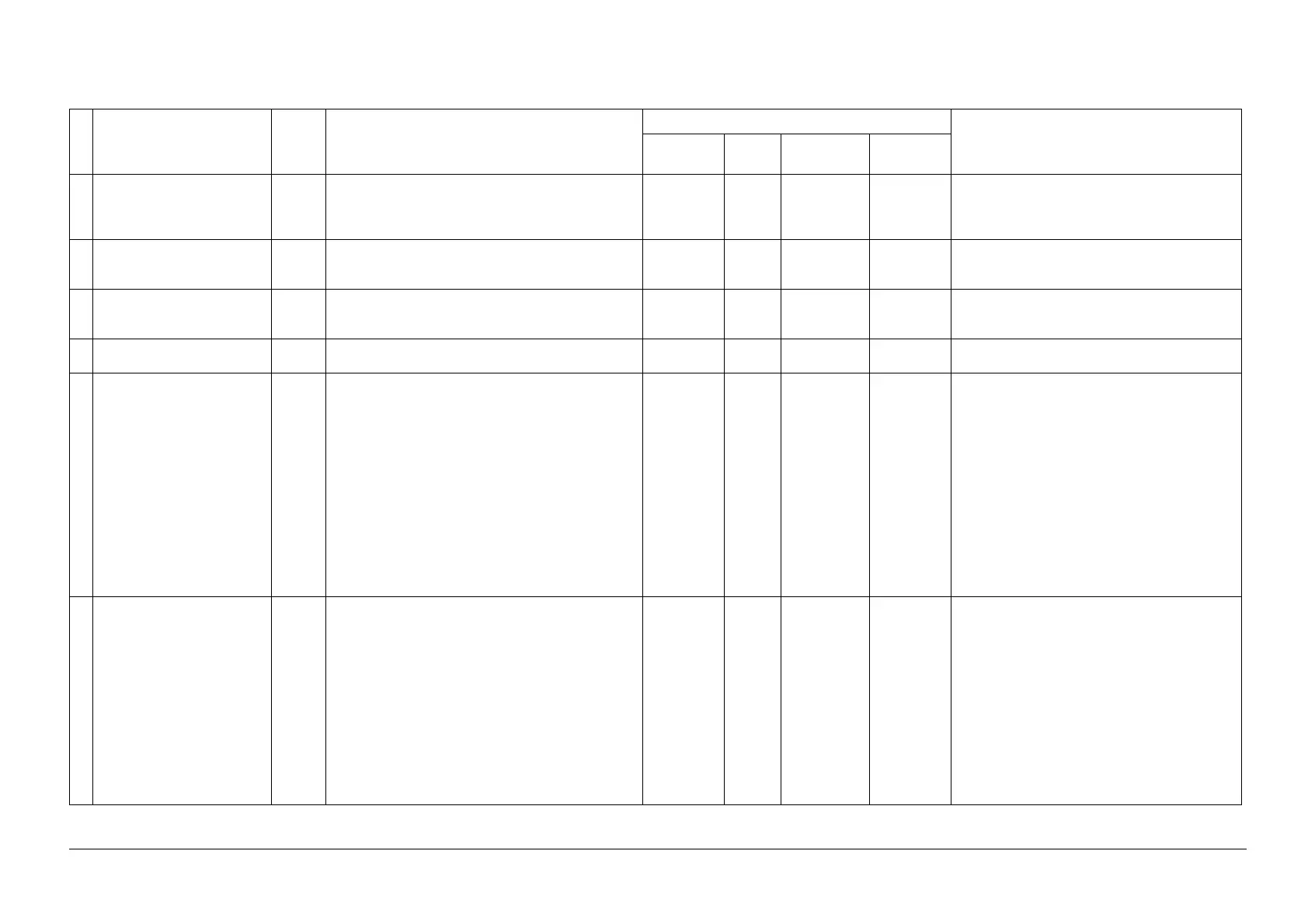

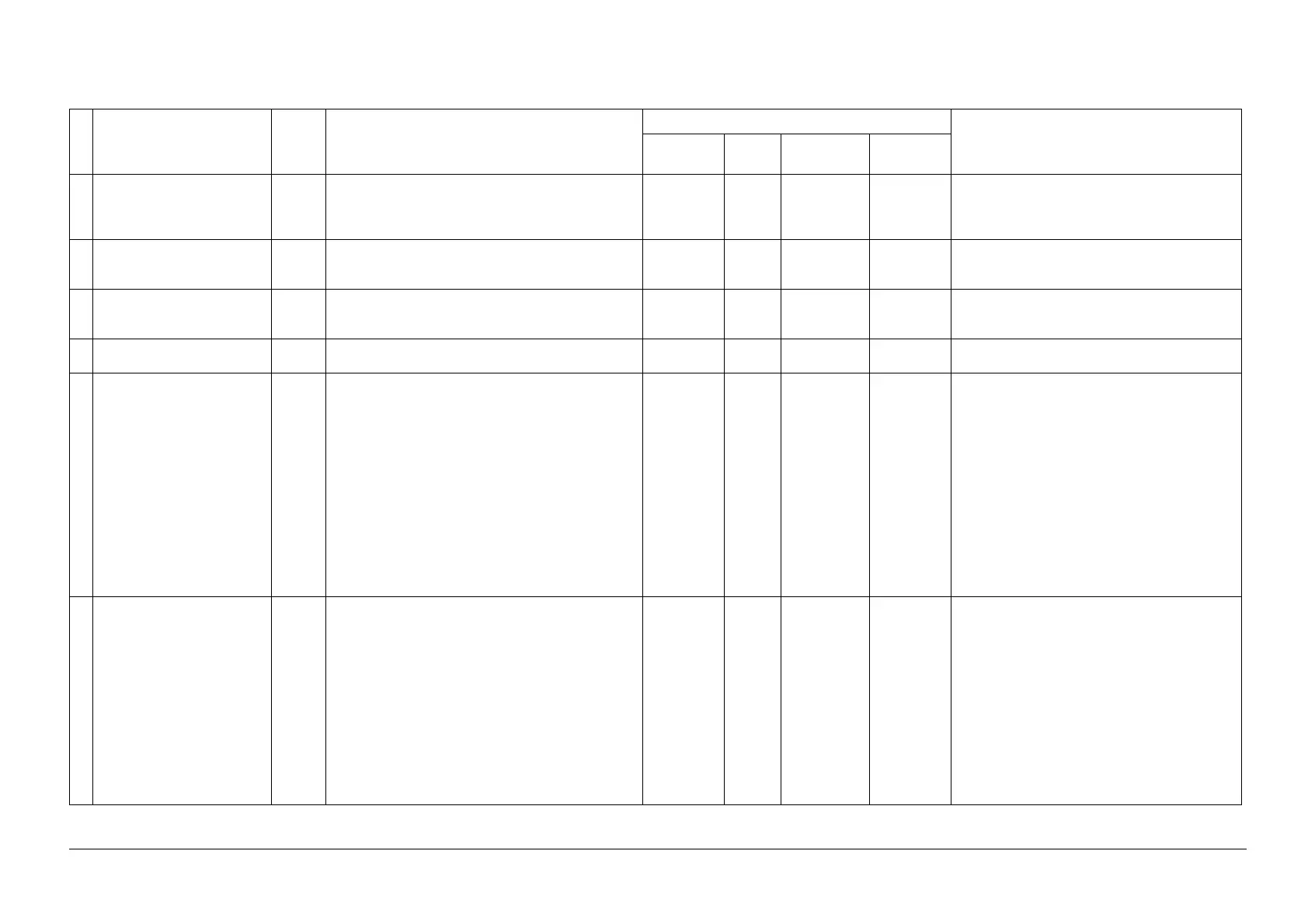

Table 1

Image Quality Problem Name SUB Details

Occurrence Condition

Interim Measures Details

Environmen

t

Side-1

Side-2 Media

Others

Conditions

1 Roll Marks PH Rubber roll mark or toner wax component may stick dur-

ing duplex print or after continuous printout depending

on the paper. This is frequently seen in gloss paper type.

All Side-1

Side-2

Stands out

even more

with Gloss

paper type

Change to a lighter paper type.

(However there might be an issue of fixing failure)

2 Condensation Copy Fusing

Unit

Sometimes patches of water droplets may be found on

paper that is printed right after machine start up.

All - Hydrated

paper is a

stress.

Use fresh paper.

3 Corrugation Stripes PH Depending on the paper, there may be Pinch Roll traces

or minor scratches in the paper feed direction. This is

more likely to occur with special paper such as Gloss.

All Heavyweight

gloss paper.

Use substitute paper (Non-gloss, lightweight

paper).

4 Gloss Uneven Side 2 Fusing

Unit

Roughness of the image may appear on the back side

with duplex print on gloss paper.

All - Coated Lower the image density.

5 Background on Coated Paper Deve The degree of fogging becomes higher for gloss paper

compared to plain paper.

All All Coated • After

stop-

ping for

a long

period

of time

under

high

humidity

•Print

with

high

image

density

Raise the developing bias DC component by 10 ~

20V and reduce the fogging on the drum. (Individual

support)

However, this will sacrifice the reproducibility of fine

lines and highlight sections.

6 Smear Transfer When the lead edge of paper reaches the Secondary

Transfer, it immediately increases the Secondary Trans-

fer section load and causes the IBT Drive Roll speed to

change (decrease in speed).

This speed change changes the relative velocity differ-

ence of photo receptor and IBT Belt surface in K color

primary transfer part, which may cause a smear (image

disorder) 96mm from the paper edge.

All • It

becomes

more

stressful

if the

basis

weight is

thicker.

• It will

stand out

more with

Gloss

paper.

BW Mode Change the value of NVM740-033 (Plain paper/

Recycled paper/Fine quality paper), 740-034

(Heavyweight/Label L), 740-035 (Extra Heavy-

weight/Label H/Postcard/Envelope), 740-036

(Gloss paper1), 740-037 (Gloss paper2) to 01.

By changing the above NVM and selecting the

above paper setting, IOT will perform FC Mode

operation regardless of the Color Mode setting of

the controller for Monochrome Print.

However, keep in mind that Yellow, Magenta, Cyan

Toner, Xero-CRU, processing machine will be con-

sumed during BW Print as well.

Loading...

Loading...