05/2014

3-32

DC SC2020

3.2.2 How to use the image quality troubleshooting (IPS)

Version 1.1

Image Quality Troubleshooting

7 Rough Black Transfer The Toner will not get transferred into the rough parts for

paper with poor smoothness and texture, and the trans-

fer will be rustled.

All Paper with

poor smooth-

ness or texture

• Change to paper with better smoothness or

texture

• 2nd Transfer Voltage Offset Adjustment

Optimize secondary transfer voltage with

(Maintenance - Adjust 2nd BTR) (Set to Minus

side).

8 Moist Paper Transfer Failure Transfer The resistance drops when the paper hydrates.

On the other hand, since K color which includes carbon

has a big dielectric loss, the necessary electric field dif-

fers from other colors.

Due to this, the necessary electric field difference

between multicolor and K color becomes big from the dif-

ference of paper resistance and the toner resistance,

which narrows the transfer latitude and creates uneven-

ness.

High humidity

environment

When feeding

paper that fits

high humidity

environment

(hydrated

paper)

K stands out Please use unopened paper.

9 Paper front edge/rear edge

Toner smear on (the edge)

Transfer When the paper that has been loop formed in transfer

fixation releases the secondary transfer nip, the rear

edge part moves to the opposite direction of the feeding

direction and occurs by touching the belt by 2nd BTR

surface or DTS HSG or a flip-up.

All When there

is an unex-

pected toner

smear in 2nd

BTR or DTS

HSG (fog-

ging).

• To control fogging, expand the cleaning field

(within the permissible limit of thin line repro-

ducibility)

• Reduce the Toner Band (within the permissi-

ble limit of density maintainability)

10 Tail Edge Transfer Failure Transfer After releasing the secondary transfer nip, the paper rear

edge part flips-up and re-transfers to the center transfer

belt from the fixing ironing effect, resulting in roughness

or white occurring on the paper rear edge part (within

10mm including blank space).

All • When

the posi-

tion of

the

paper

worsens

•Perfor-

mance

limit

11 MWS(Side2) (MicroWhiteS-

pots)

Transfer When the secondary transfer part resistance is high

such as first thing in the morning of low humidity environ-

ment, the transfer latitude of multicolor and single color

is narrow and the voltage it set towards the multicolor.

Due to this, the voltage becomes too much for the dingle

color and fine white dots may appear on the image in

Side2 from the electric discharge phenomenon of the

transfer nip.

Low humidity

environment

Side2 is

stress.

• Paper

with poor

smooth-

ness is a

stress

• Paper left

out in low

humidity

environ-

ment is a

stress

First thing in

the morning

of low tem-

perature/low

humidity

environment

is a stress.

2nd Transfer Voltage Offset Adjustment

Optimize secondary transfer voltage with (Mainte-

nance -> Adjust 2nd BTR) (Set to Minus side).

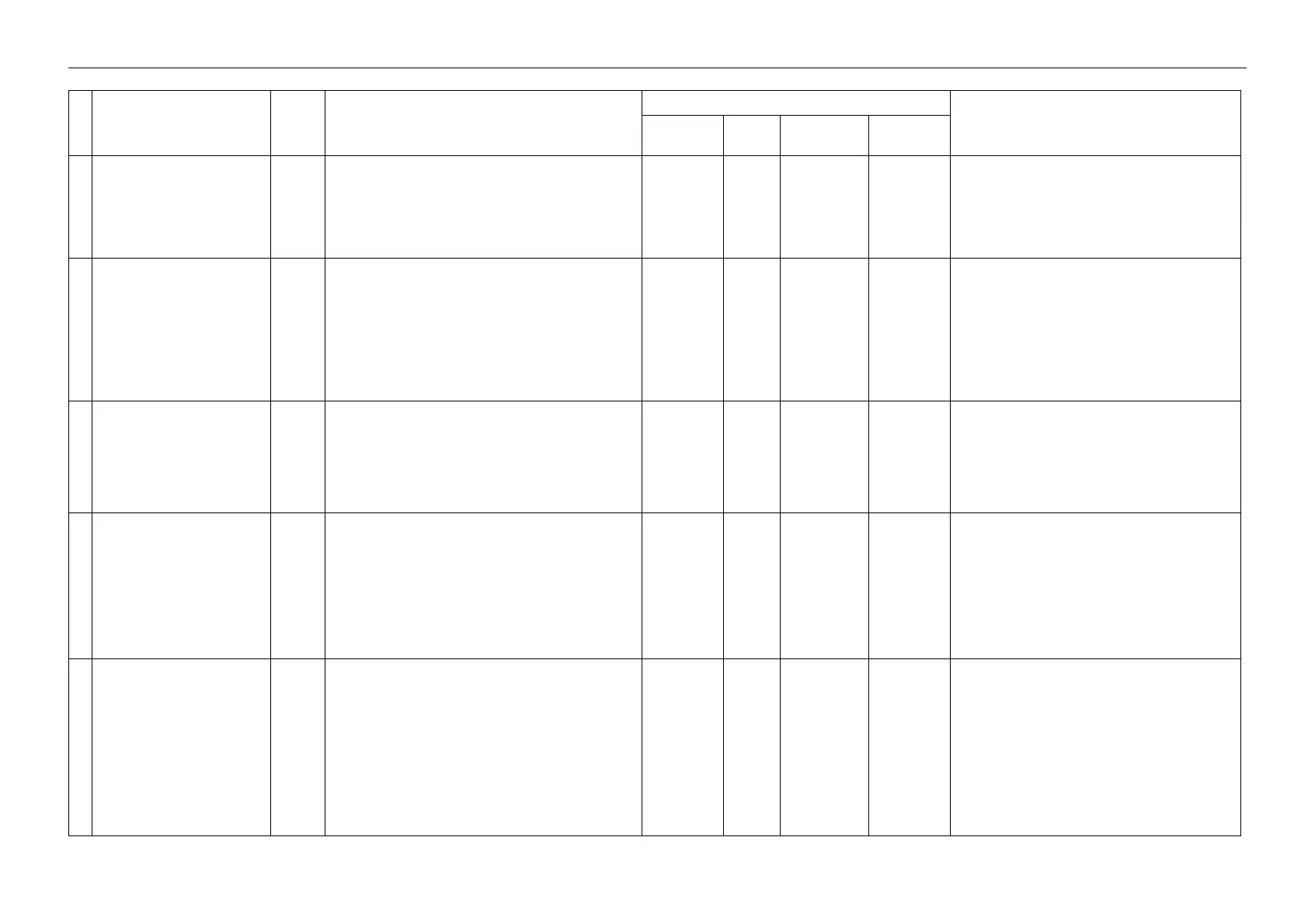

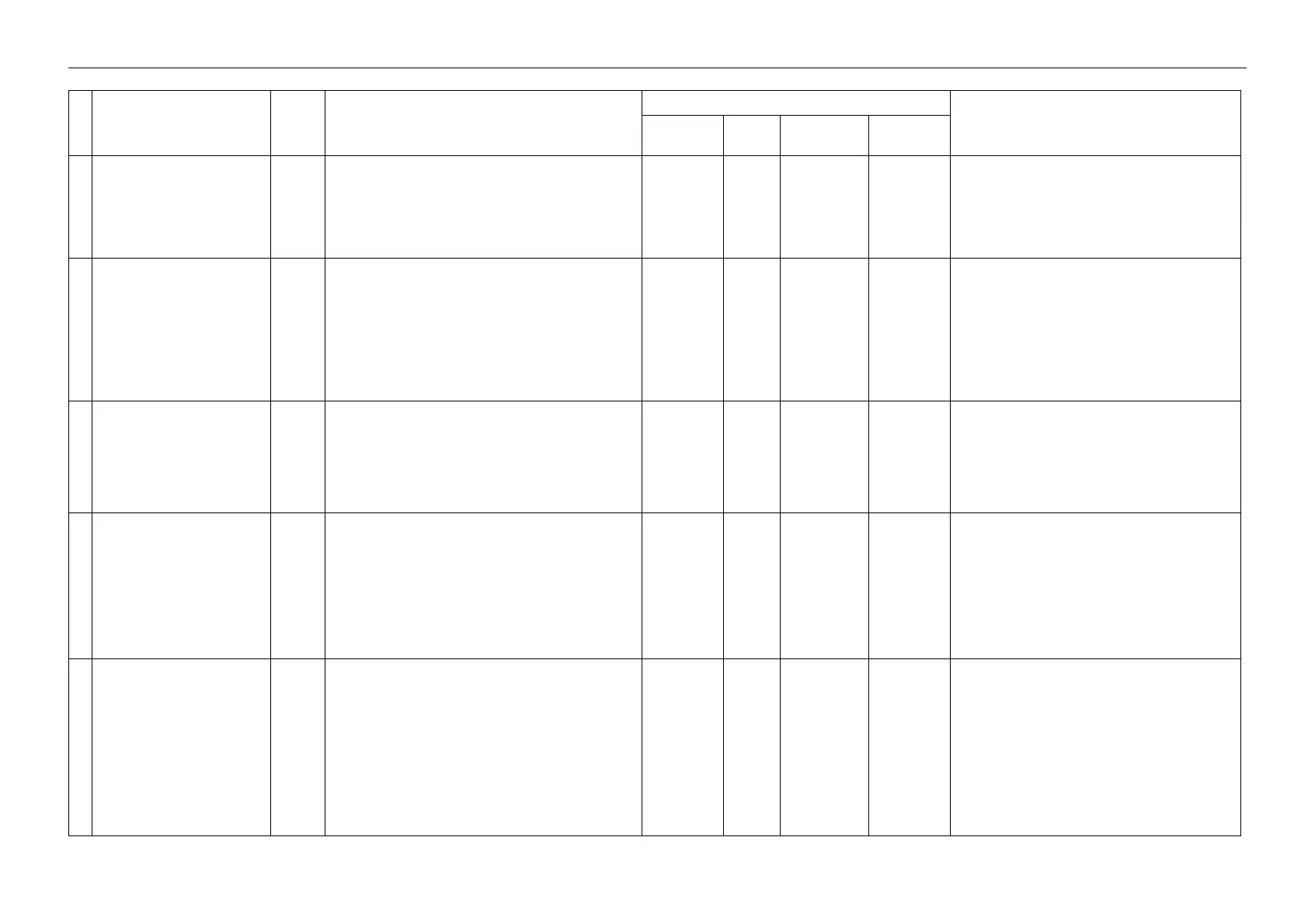

Table 1

Image Quality Problem Name SUB Details

Occurrence Condition

Interim Measures Details

Environmen

t

Side-1

Side-2 Media

Others

Conditions

Loading...

Loading...