05/2014

1-6

DC SC2020

1.3 Detailed Contents of the Service Call

Version 1.1

Service Call Procedure

1.3 Detailed Contents of the Service Call

1.3.1 Initial Actions

1. Ask the operator(s) about the machine condition.

• How often and where do paper jams have been occurring recently

• How is the copy quality

2. Record the copy meter readings.

3. Inspect any error copies, then check the machine.

4. Check the print samples from previous service calls and the Service Log.

1.3.2 Checking Reproducibility of Problem

1. Check the problem status by performing the Level 1 Troubleshooting in [Chapter 2 Troubleshoot-

ing].

2. Perform the applicable Level 2 Troubleshooting FIP in [Chapter 2 Troubleshooting].

3. If there are no applicable items, troubleshoot by referring to [Chapter 7 BSD].

1.3.3 Checking Copy Quality

1. Make several sheets of copies using the Test Chart (499T 00247), then check the quality of the cop-

ies.

1.3.4 TRIM Servicing

Perform TRIM servicing during a service call to maintain the machine performance.

1. Follow the TRIM Check List to perform the required TRIM items.

2. Check for parts that require periodical cleaning/replacement (consumables, parts) by referring to the

TRIM Chec List, the Periodic Replacement Parts/Consumables List, and the Maintenance Report,

and clean them if necessary. If a replacement is done, make sure that you enter the CE Mode and

use Printer Diag > Parameter > Life to clear the applicable counter(s).

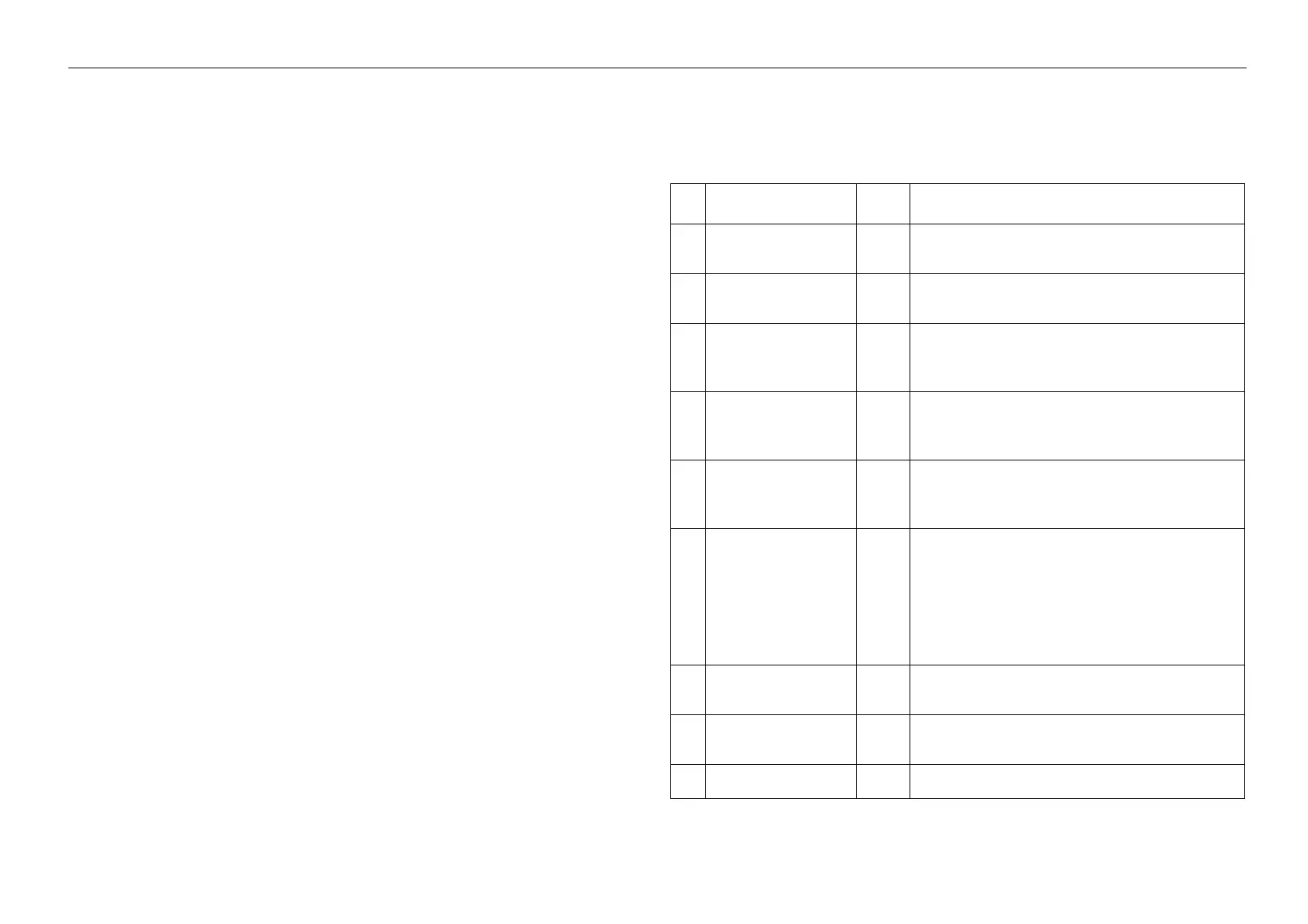

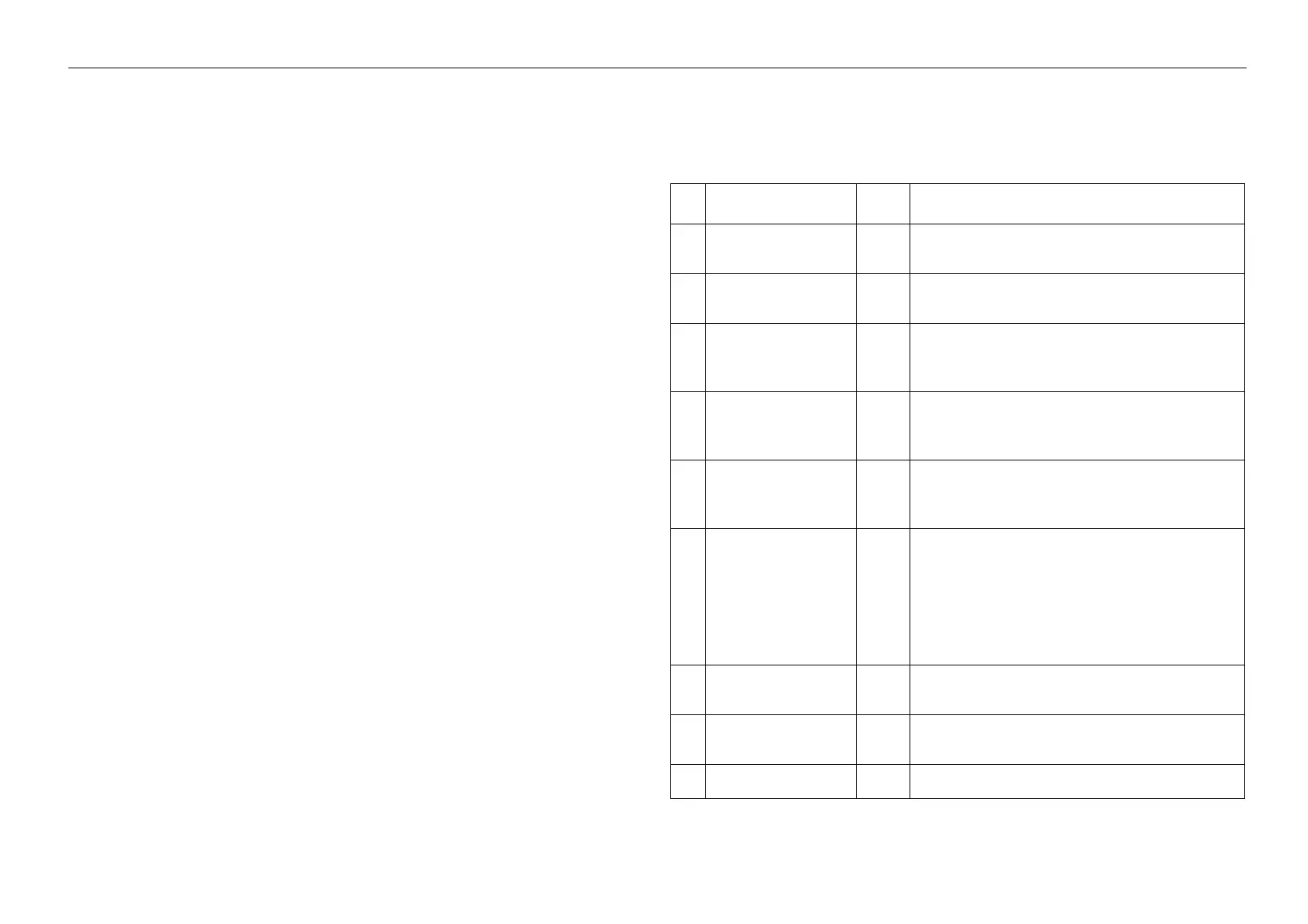

1.4 TRIM Check List

C: Perform checking. Clean, replace, or feed if necessary.

O: Always perform cleaning and checking.

*: Always perform replacement service at the specified interval.

Table 1

No. Servicing Items

Every

time Service Details

1.1 Pre-servicing Check

(Check the machine oper-

ation sound)

C • Activate the machine and check that abnormal noise is

not heard.

1.2 Pre-servicing Check

(Copy and print the Test

Chart)

C • Make several sheets of copies using the Test Chart

(499T 00247), then check the quality of the copies.

2 Clean the interior of the

machine

(Clean the paper transport

system)

C • Clean any paper dust and toner residue in the paper

path and on the jam sensor.

• Especially, clean the operation section of the operator

carefully.

3 Cleaning the IIT C • Clean the Platen Glass surface and the Platen Cushion

with the optical cleaning cloth.

• Clean the Reflector, back of the Platen Glass, mirrors

and lens with the optical cleaning cloth.

4 Clean the DADF C • Clean the Feed Roll, Nudger Roll, and Retard Roll with

a cloth that has been wrung dry.

• Clean the DADF Platen Glass with the optical cleaning

cloth.

5 Safety Check O • Make sure that the power plug is plugged in properly.

• Make sure that the power cords are not cracked and no

wires are exposed.

• Make sure that no extension cord with insufficient

length or power cord outside the specification, such as

an off-the-shelf power strip, is being used.

• Make sure that a single socket does not have multiple

power plugs plugged into it.

6.1 Post-servicing check

(Copy Quality Check)

C • Make several sheets of copies using the Test Chart

(499T 00247), then check if the quality satisfies the

specification.

6.2 Post-servicing check

(Check the machine oper-

ation)

C • Check the paper feed and abnormal noise.

6.3 Post-servicing check

(Check the meter)

C • Create the Service Log and Service Report.

Loading...

Loading...