05/2014

3-34

DC SC2020

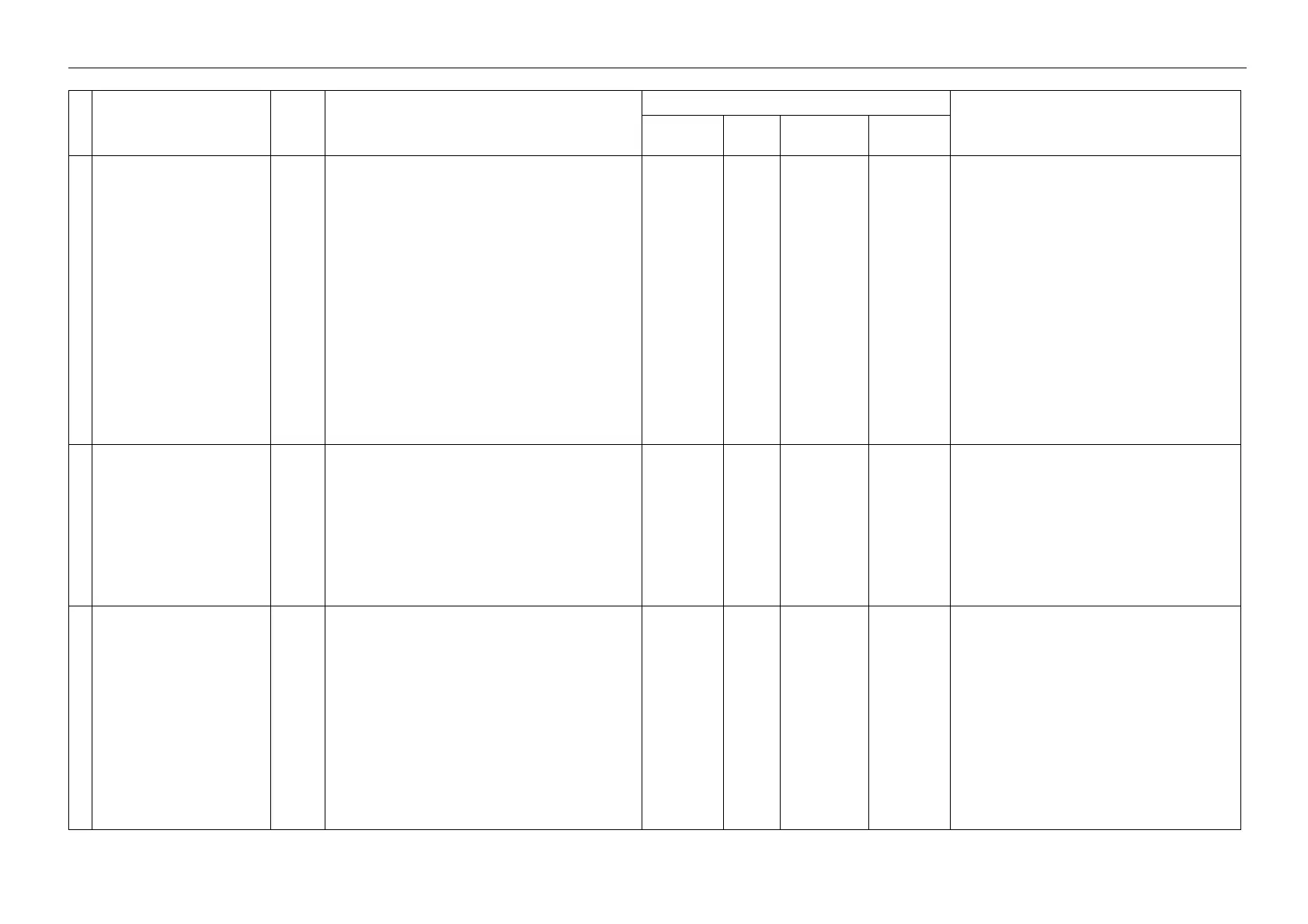

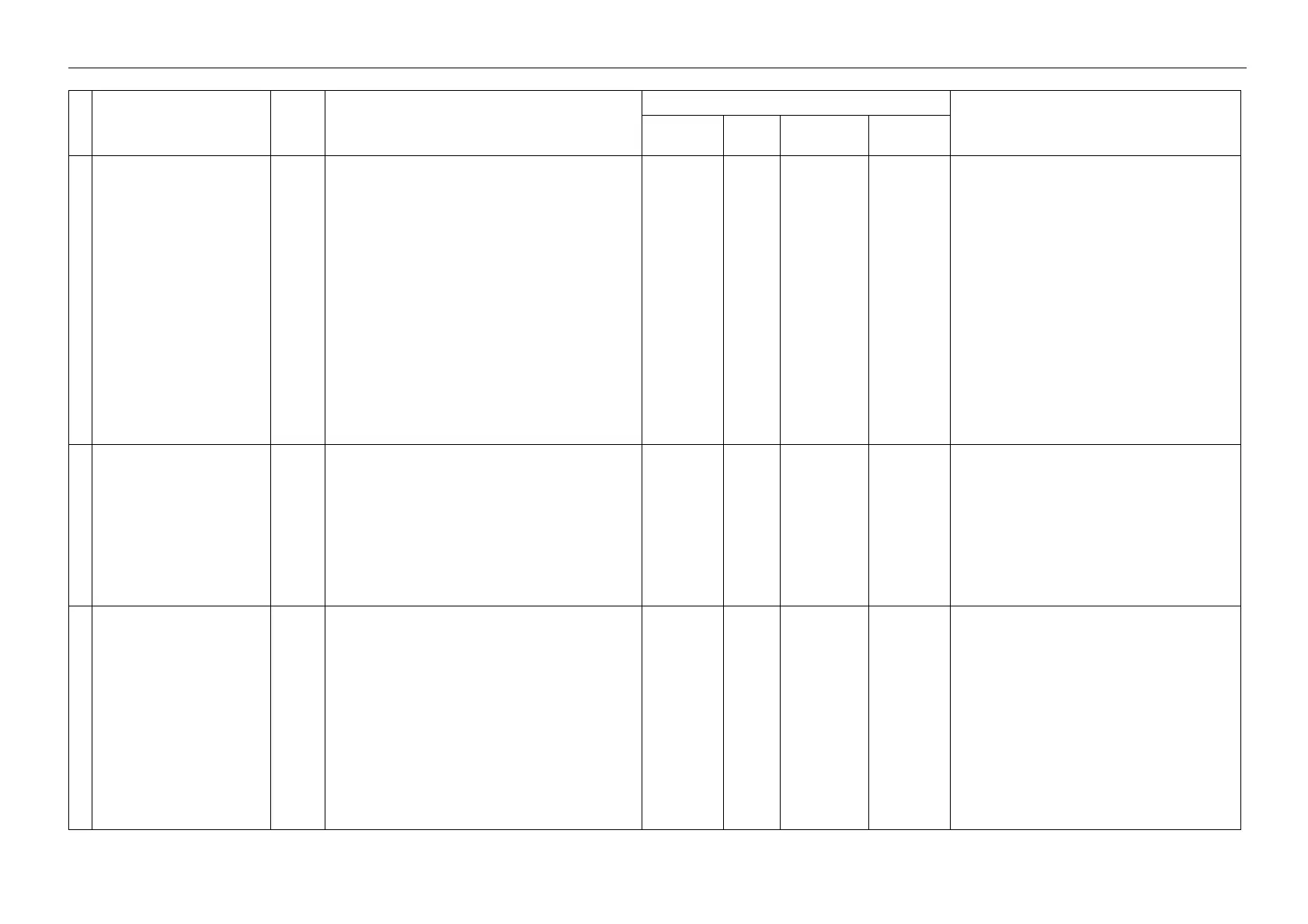

3.2.2 How to use the image quality troubleshooting (IPS)

Version 1.1

Image Quality Troubleshooting

20 Heavyweight paper image

bleeding

Transfer The paper jumps up after the paper rear edge goes

through the Reg Shoot and move closer to the center

transfer belt.

Due to the electric discharge phenomenon occurs in

secondary transfer prenip part, part of axial direction

around 25mm from the rear edge of heavyweight paper

may get blurred (Toner gets scattered).

All • Basis

weight is

heavy.

•The

paper

resil-

ience is

strong

•The

paper

feeding

direction

and the

direction

of the

paper

weave is

parallel

•K color

is easy

to occur

• Tends

to occur

when

the

paper

leading

edge is

curled

up.

Down curl the rear edge of the paper.

21 Detachment unevenness/

Detachment failure/Rib line/Fix-

ing failure

Fusing

Unit

If there is a high density image part, gloss unevenness/

detachment failure/rib line/fixing failure may occur.

All Side-1

Side-2

Paper such as

gloss paper/

hydrated

paper or paper

with weak

resistance

• Use fresh paper.

• Reverse the image.

(Make sure there is no high density image on

the front edge.)

• Lower the density.

• Lower the high density with TRC Adjust.

• Lower the Cin.

• If it occurs in LEF feed, switch the feeding

direction from LEF feed to SEF feed.

22 Toner Droplet Contamination Deve Toner smear in drops may occur. All All All • After

stop-

ping for

a long

period

of time

under

high

humidity

•Print

with

high

image

density

Perform processing machine stirring mode when it

is left under high humidity environment for a long

period of time.(NVM762-119: 0 => 1)

Table 1

Image Quality Problem Name SUB Details

Occurrence Condition

Interim Measures Details

Environmen

t

Side-1

Side-2 Media

Others

Conditions

Loading...

Loading...