3.Paper Delivery Problems

701

J080 (Paper Slippage)

Cause:

Paper feed is delayed. This may occur if the paper is slippery.

Solution:

1. In Advanced Settings for the custom paper in use, set Regist Jam Detection with Feed Dir to Off.

(1341-02)

2. Print the image. Is the problem resolved?

Consult the product specialist.

When you set Regist Jam Detection with Feed Dir to Off, the printed image may become

misaligned at the leading edge.

If the paper is not registered as a custom paper, use SP1-918-001 to 013: Subscan Reg Jam

Detect

J082 (Thick Paper)

A jam has occurred with paper of Thickness 5 or thicker.

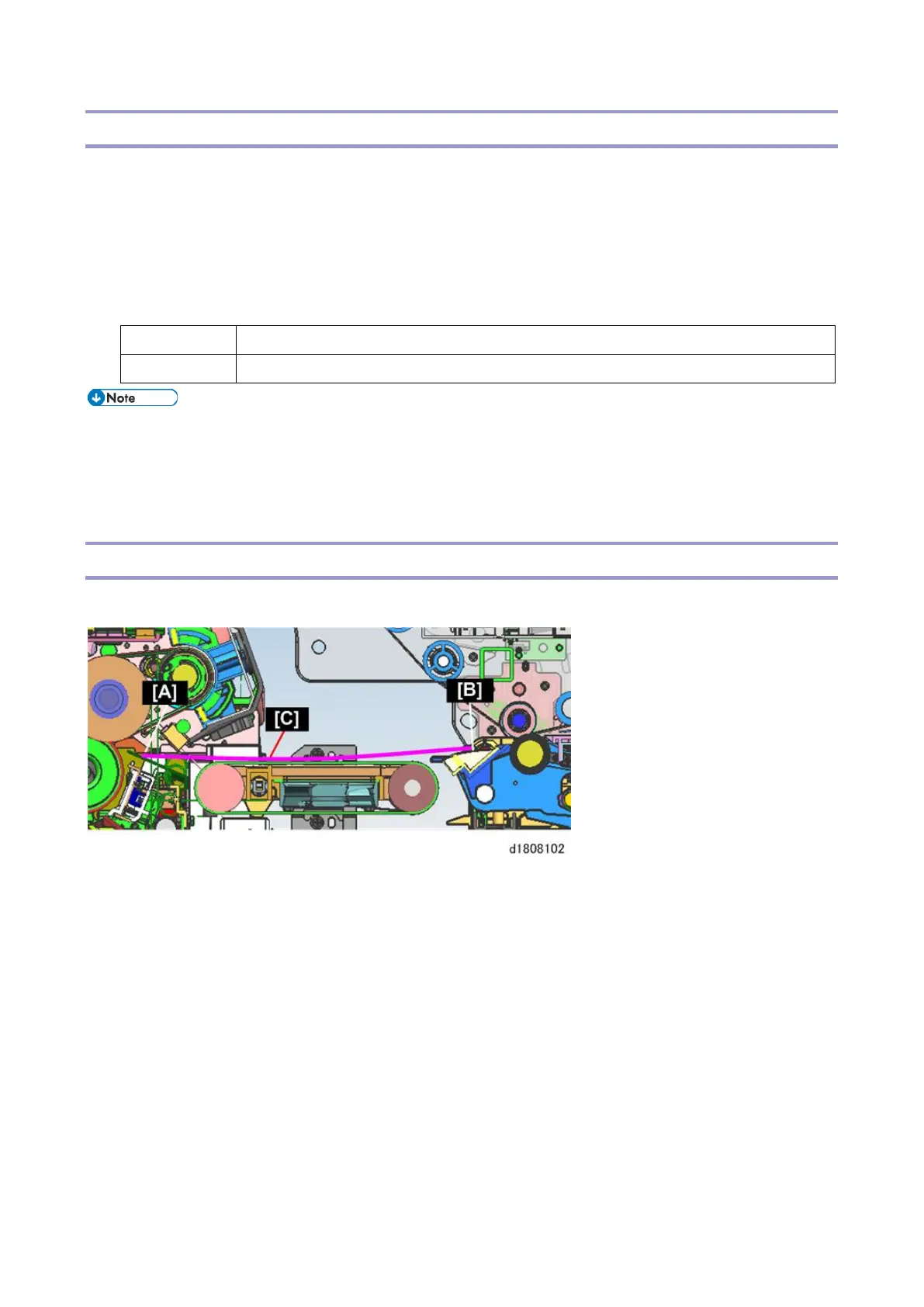

If very stiff Thickness 5 paper, or paper of Thickness 6 or thicker is fed, and the leading edge is on the

fusing guide plate [A] while the trailing edge is on the transfer exit guide [B], because of the stiffness,

only a small part is in contact with the paper transport belt [C]. As a result, the paper cannot be fed, and

JAM82 occurs.

Paper with slick surfaces, such as coated paper, also tends to slip, causing the same jam.

Cause:

This can occur when:

Feeding the paper sizes B5 LEF, A4 LEF, LT LEF

The paper is of Thickness 5 and extremely stiff, or of Thickness 6 or higher (in particular, rigid

paper or slippery paper)

Solution:

The basic solution is to operate the lever of the paper transport belt (PTB) unit to raise the unit, in order

Loading...

Loading...