4.Troubleshooting for Peripheral Units

832

SP1984-101 to 131 to lower fusing temperature by 5°C to 10°C to reduce the amount of curl. You

can also use the Custom Paper Settings > 44: [Fusing Heat Roller Temperature Adj.] to adjust the

fusing temperature.

If this does not solve the problem, adjust the positions of the main jogger and LE stopper with

these SP codes:

SP6-602/SP6-608

SP6-603/SP6-609

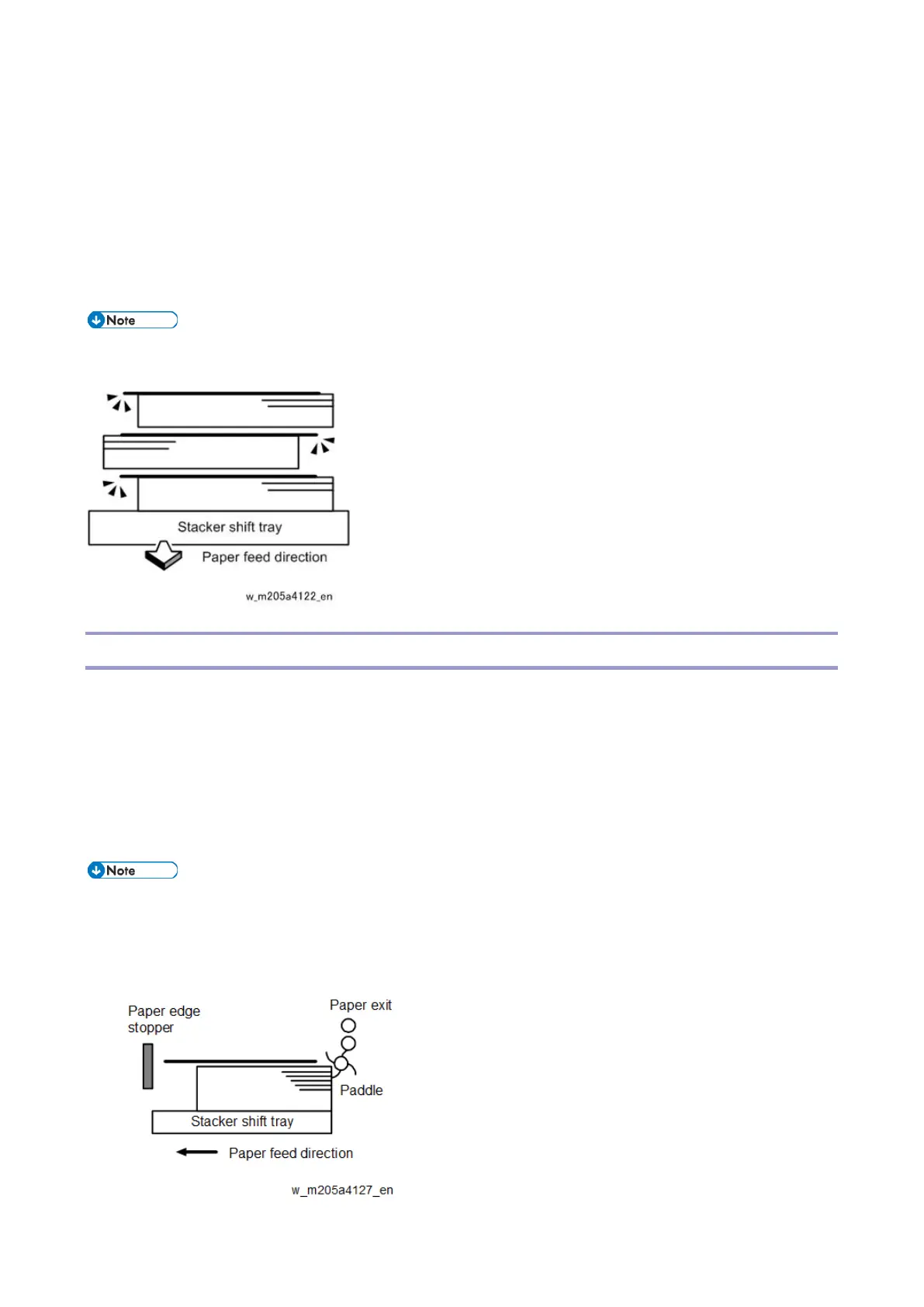

The top sheet of each offset bundle of delivered sheets may protrude above the rest of the

bundle by about 7 mm.

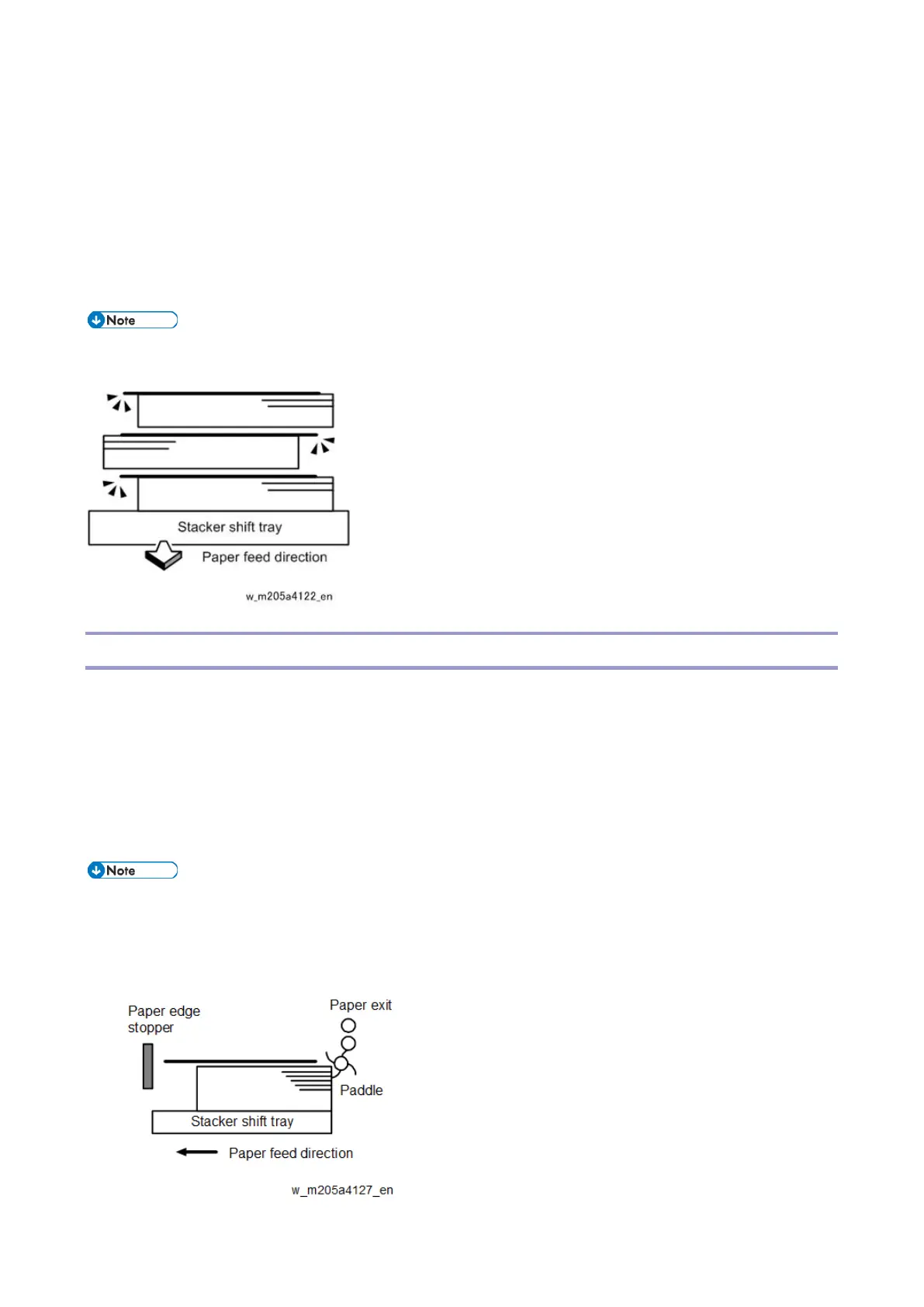

Delivered Sheets Are Not Aligned (Paper Thickness 1 or Less)

Cause

Despite the air assist system, when sheets (particularly paper that is relatively soft and has strong

transport resistance, such as thin or coated paper) are delivered to the stacker tray, because of paper-

to-paper friction, the paddle fails to pull the trailing edge back into the front guide, resulting in

misalignment.

The paper edge stopper also fails to push back the protruding leading edge.

Thin paper is paper with thickness 1 or less.

How the problem occurs

1. An uncurled sheet is delivered to the stacker shift tray.

Loading...

Loading...