11. OPTIONS AND PERIPHERAL EQUIPMENT

11 - 20

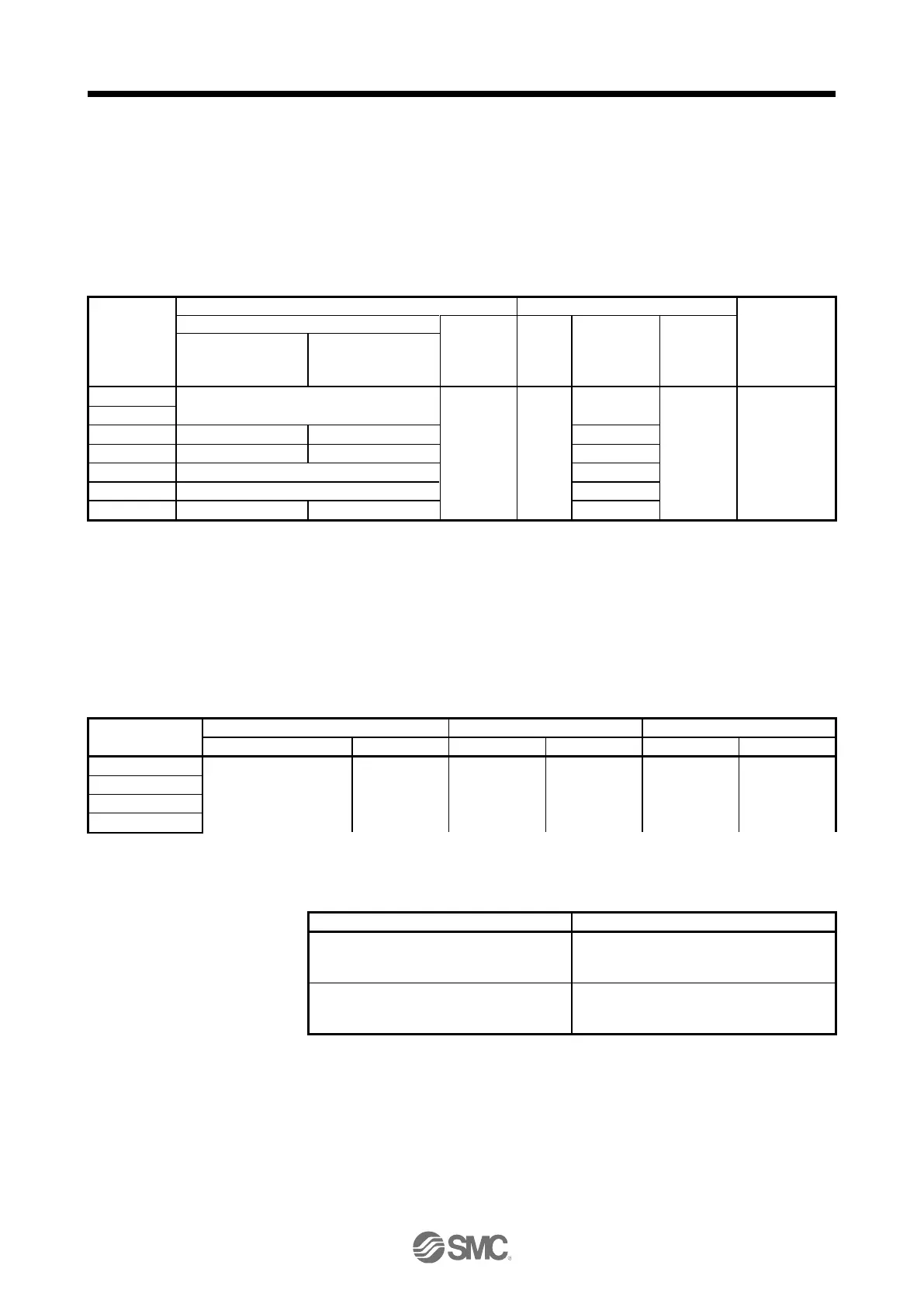

11.6 Molded-case circuit breakers, fuses, magnetic contactors (recommended)

(1) For main circuit power supply

To prevent the driver from smoke and a fire, select a molded-case circuit breaker which shuts off

with high speed.

Always use one molded-case circuit breaker and one magnetic contactor with one driver.

When using a fuse instead of the molded-case circuit breaker, use the one having the specifications

given in this section.

Molded-case circuit breaker (Note 1, 3)

Magnetic

contactor

(Note 2)

Power factor

Improving reactor is

not used

Power factor

Improving reactor is

used

S-N10

(

Mitsubishi

Electric

Corporation

)

)

When having the driver comply with the IEN/EN/UL/CSA standard, refer to app.4.

Use a magnetic contactor with an operation delay time (interval between current being applied to the coil until closure of

contacts) of 80 ms or less.

Use a molded-case circuit breaker with equal or higher operating characteristics.

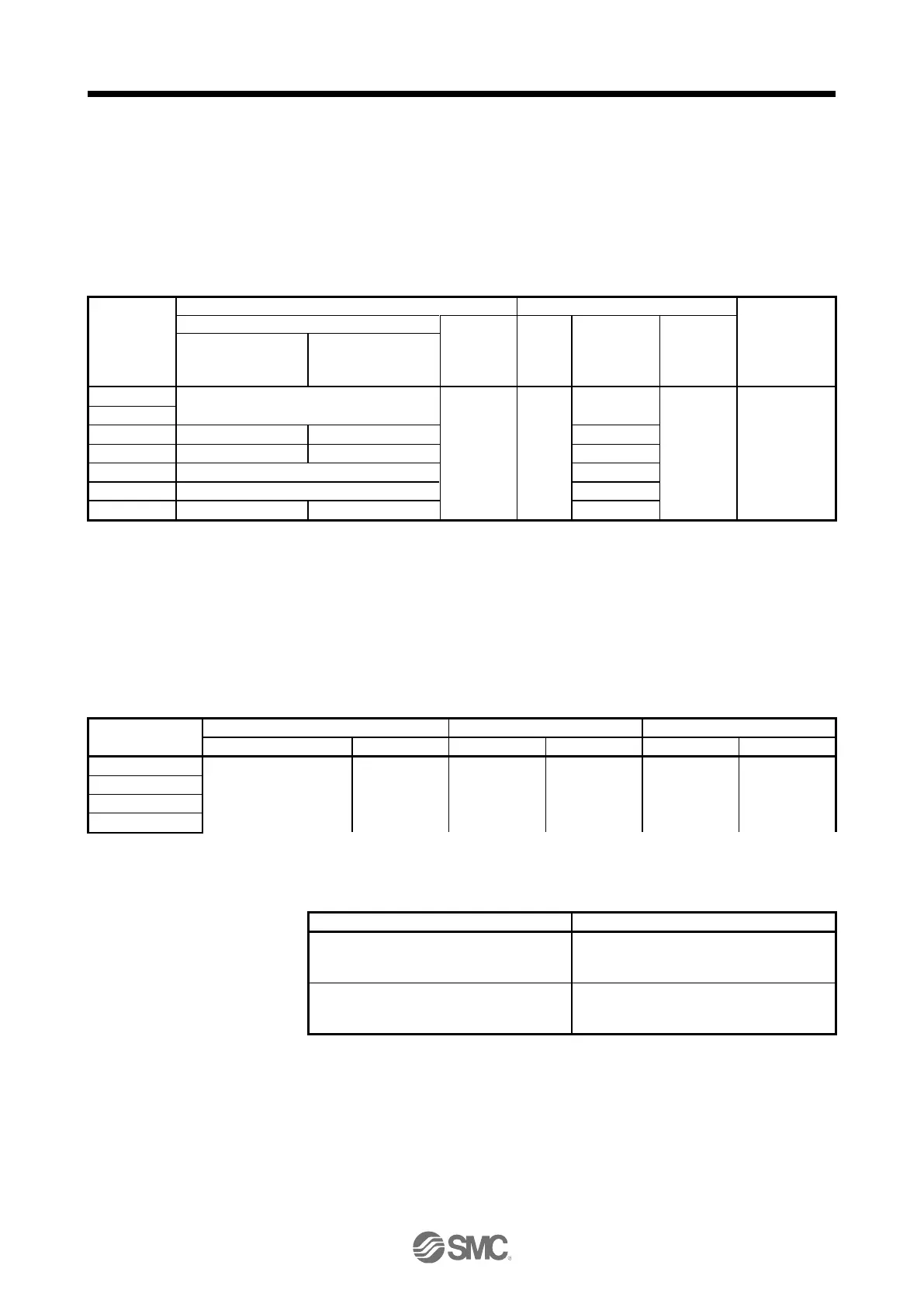

(2) For control circuit power supply

When the wiring for the control circuit power supply (L11, L21) is thinner than that for the main circuit

power supply (L1, L2, L3), install an overcurrent protection device (molded-case circuit breaker or

fuse) to protect the branch circuit.

Molded-case circuit breaker

11.7 Relay (recommended)

The following relays should be used with the interfaces

Digital input (interface DI-1)

Relay used for digital input command signals

To prevent defective contacts, use a relay for

small signal (twin contacts).

(Ex.) Omron : type G2A, MY

Digital output (interface DO-1)

Relay used for digital output signals

Small relay with 12 V DC or 24 V DC of rated

current 40 mA or less

(Ex.) Omron : type MY

Loading...

Loading...