1. FUNCTIONS AND CONFIGURATION

1 - 22

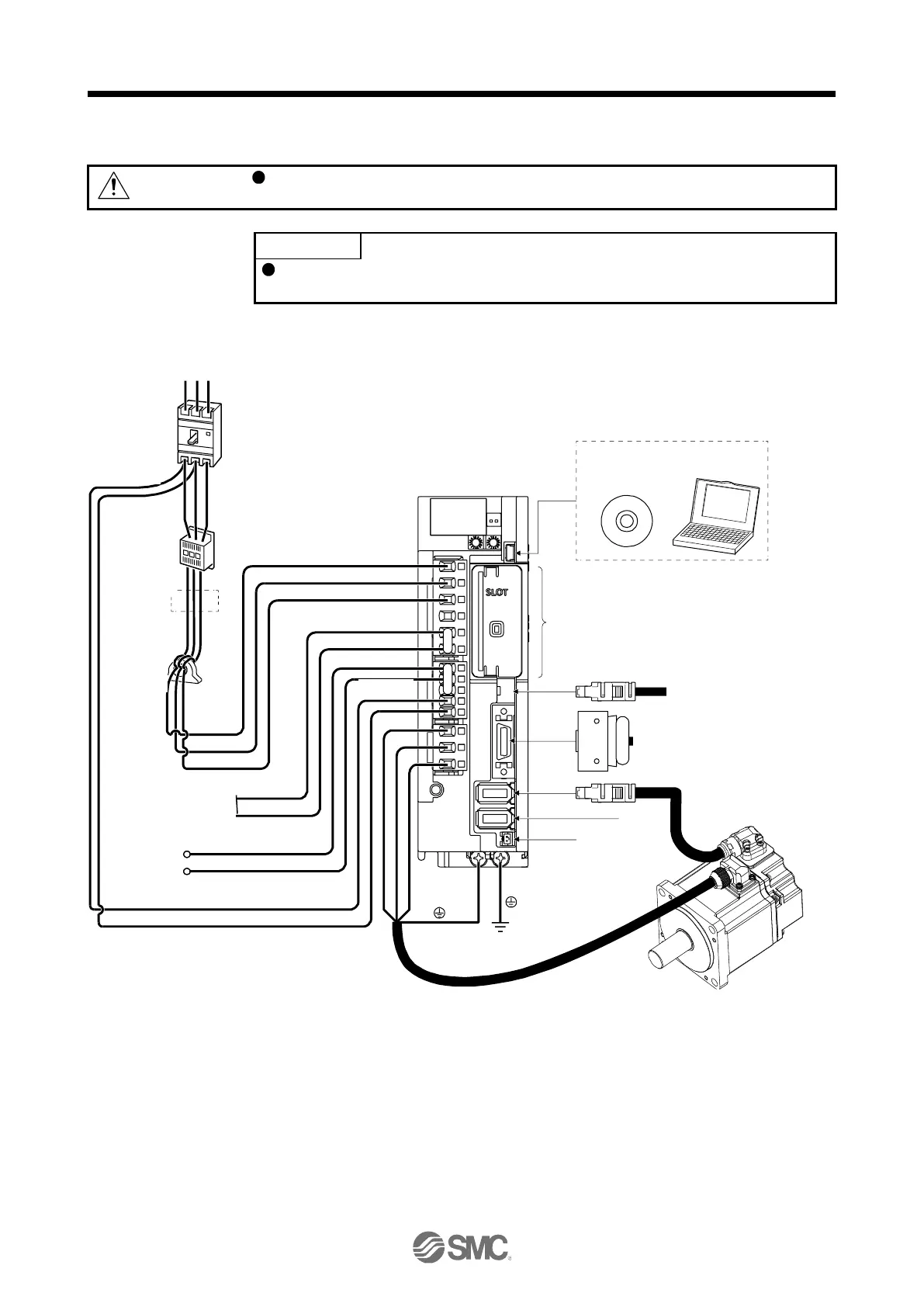

1.9 Configuration including peripheral equipment

Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the driver may

cause a malfunction.

Equipment other than the driver and servo motor are optional or recommended

products.

(1) LECSN2-T□

The diagram shows LECSN2-T7.

CN4

Line noise

filter

(FR-BSF01)

CN5

Regenerative

option

P+

C

L11

L21

P3

P4

Personal

computer

MR Configurator2

Netw ork module dependence (Note 6)

CN8

CN2

CN2L (Note 4)

CN3

W

V

U

L1

L2

L3

(Note 3)

Magnetic

contactor

(MC)

(Note 1)

Power factor

improving DC

reactor

(FR-HEL)

Junction terminal

block

To safety relay or MR-J3-D05

safety logic unit

Battery

Molded-case

circuit breaker

(MCCB)

R S T

(Note 2)

Pow er supply

Servo motor

D (Note 5)

For 1-phase 200 V AC to 240 V AC, connect the power supply to L1 and L3. Leave L2 open. Refer to section 1.3 for the

power supply specifications.

Depending on the main circuit voltage and operation pattern, bus voltage decreases, and that may cause the forced stop

deceleration to shift to the dynamic brake deceleration. When dynamic brake deceleration is not required, slow the time to

turn off the magnetic contactor.

CN2L cannot be used. Connect the encoder cable to CN2.

Always connect between P+ and D terminals. When using the regenerative option, refer to section 11.2.

For the network card connections, refer to chapter 18,19,20

I/O connector

or I/O cable

Loading...

Loading...