10-22

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

HSTHST

HSTHST

HST

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

CK22/CK22H

k

j

A

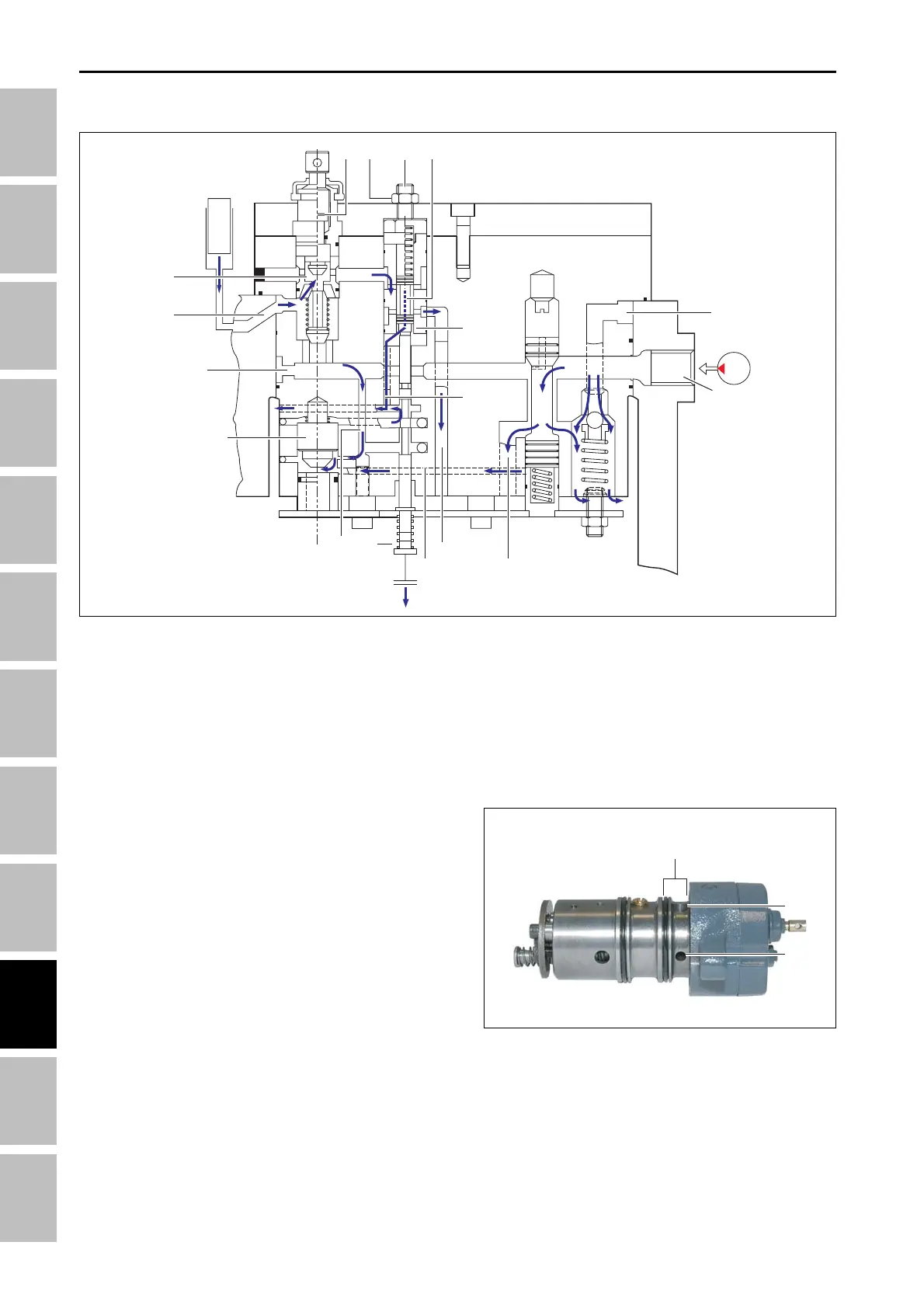

D. LOWERING

Lowering:

When the control spool (1) moves downward, the fluid

passage between (a) and (b) ports are blocked as

same as when the valve is in the neutral position.

The hydraulic fluid drawn through the (b) port is drained

through the drain hole (c) on the bottom of the regula-

tor piston. The hydraulic fluid drawn through the (a)

port is supplied to the bottom of the pilot through the

passage (d) to lift the pilot valve. Then, this fluid is

drained as the fluid on the bottom of the regulator pis-

ton is drained through the passage (e).

As the control spool moves downward, the discharge

valve (2) moves downward by the upper spring to open

the drain passage. Therefore, the lifting arm is low-

ered as the fluid in the lifting cylinder is drained through

the drain passage (f).

The small oil hole (g) on the bottom of the discharge

valve is to drain the fluid from the top of the discharge

valve when the exhaust valve is closed again.

The fluid on the top of the discharge valve is drained

through this hole and the fluid passage (h).

Lowering speed adjust valve:

When turning the handle of the lowering speed adjust

valve (3) from outside, the size of the fluid passage (i)

is adjusted and, therefore, the lowering speed of the

lifting arm can be adjusted. When turning the handle

clockwise to its end, passage is completely blocked

and the lifting arm can be locked at a certain position.

Pilot valve (12):

The pilot valve (4) delays the initial fluid flow by open-

ing or closing the control spool to help the smooth

lifting arm operation.

Control sensitivity adjustment:

The opening timing of the spool (1) can be adjusted by

adjusting the position of the spool with unscrewing the

lock nut (5) and then adjusting the bolt (6). It means

that the sensitivity of the control spool can be adjusted.

Refer to “Measurement and adjustment” in this chap-

ter for detailed information.

Safety valve:

The section (A) in the figure is the chamber that sup-

plies the cylinder with oil. The hole (j) in the sectional

view is connected to the hole (k) which is connected to

the safety valve.

If the hydraulic lifting arm is applied with abnormal im-

pact or excessive load, the MLS valve can be damaged.

However, the hydraulic fluid in the lifting cylinder is

drawn to the (k) port through the port (j) by the outer

force. Then, it opens the safety valve, which is set to

200 kgf/cm

2

, is drained to the outside.

T46WA32A

T46WA33A

2

6

1

4

e c

f

d

3

b

k

i

5

a

g

h

HYDRAULIC SYSTME - OPERATING PRINCIPLE

Loading...

Loading...