2-61

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

HSTHST

HSTHST

HST

CK22/CK22H

7.2 INSPECTION FOR OVERHAUL

7.2.1 CYLINDER HEAD

A. CYLINDER HEAD SURFACE FLATNESS

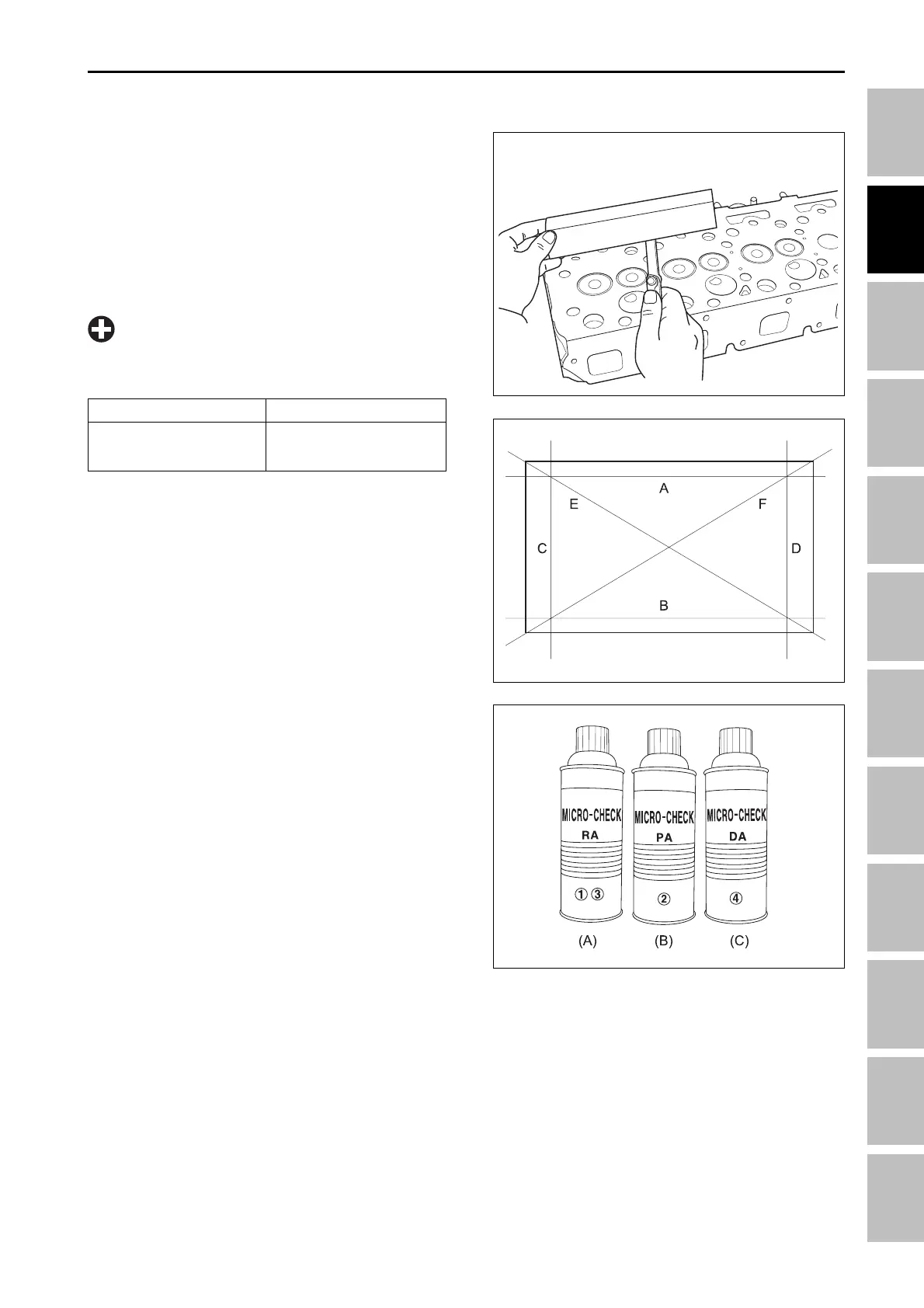

1. Thoroughly clean the cylinder head surface.

2. Place a straightedge on the cylinder head and mea-

sure the clearance with a feeler gage as shown in

the figure.

3. If the measurement exceeds the allowable limit, re-

place the cylinder head.

196W2B1A

196W2B0A

196W2A9A

Item

Flatness

Allowable limit

0.05 mm

0.0019 in.

•

Do not place the straight edge on the combustion

chamber.

IMPORTANT

B. CYLINDER HEAD SURFACE FLAW

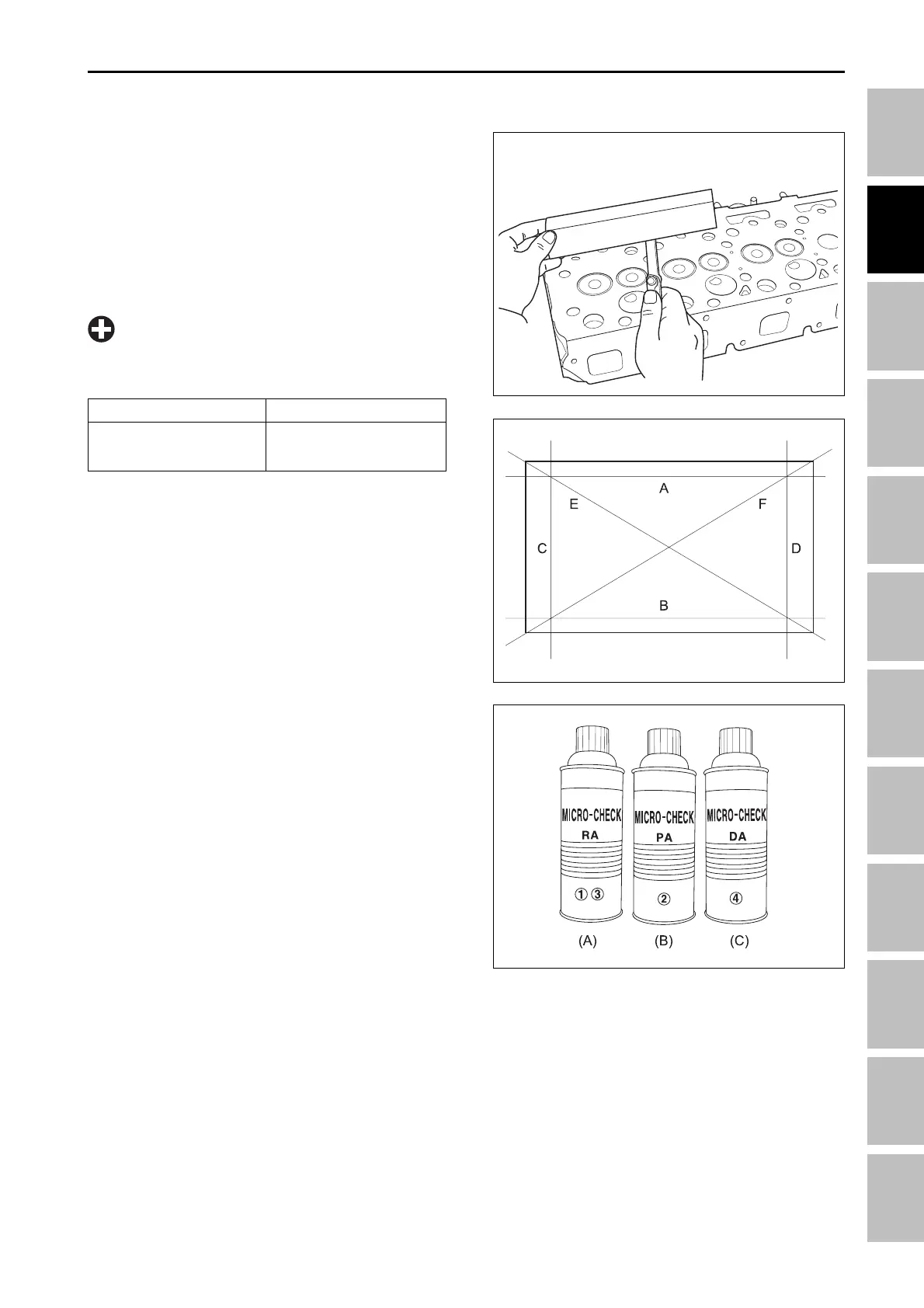

1. Clean the cylinder head surface with the detergent

(B).

2. Spray the cylinder head surface with the red perme-

ative liquid (A).

3. Wash away the red permeative liquid on the cylin-

der head surface with the detergent (B) after ten

minutes.

4 Spray the cylinder head surface with the white de-

veloper (C).

5. If any flaw is found such as a red mark, replace the

cylinder head.

ENGINE - SERVICING

Loading...

Loading...