10-31

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

HSTHST

HSTHST

HST

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

CK22/CK22H

•

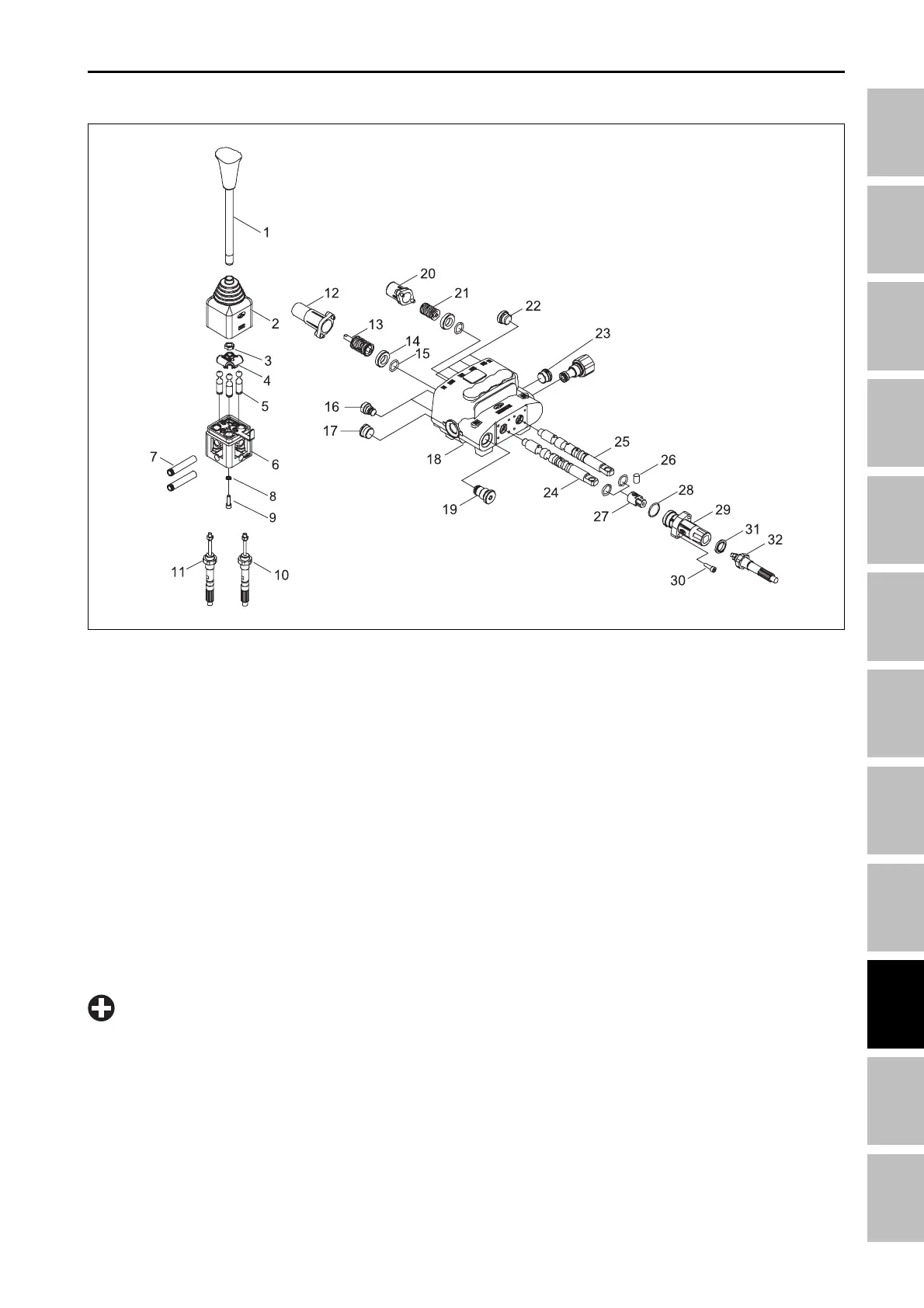

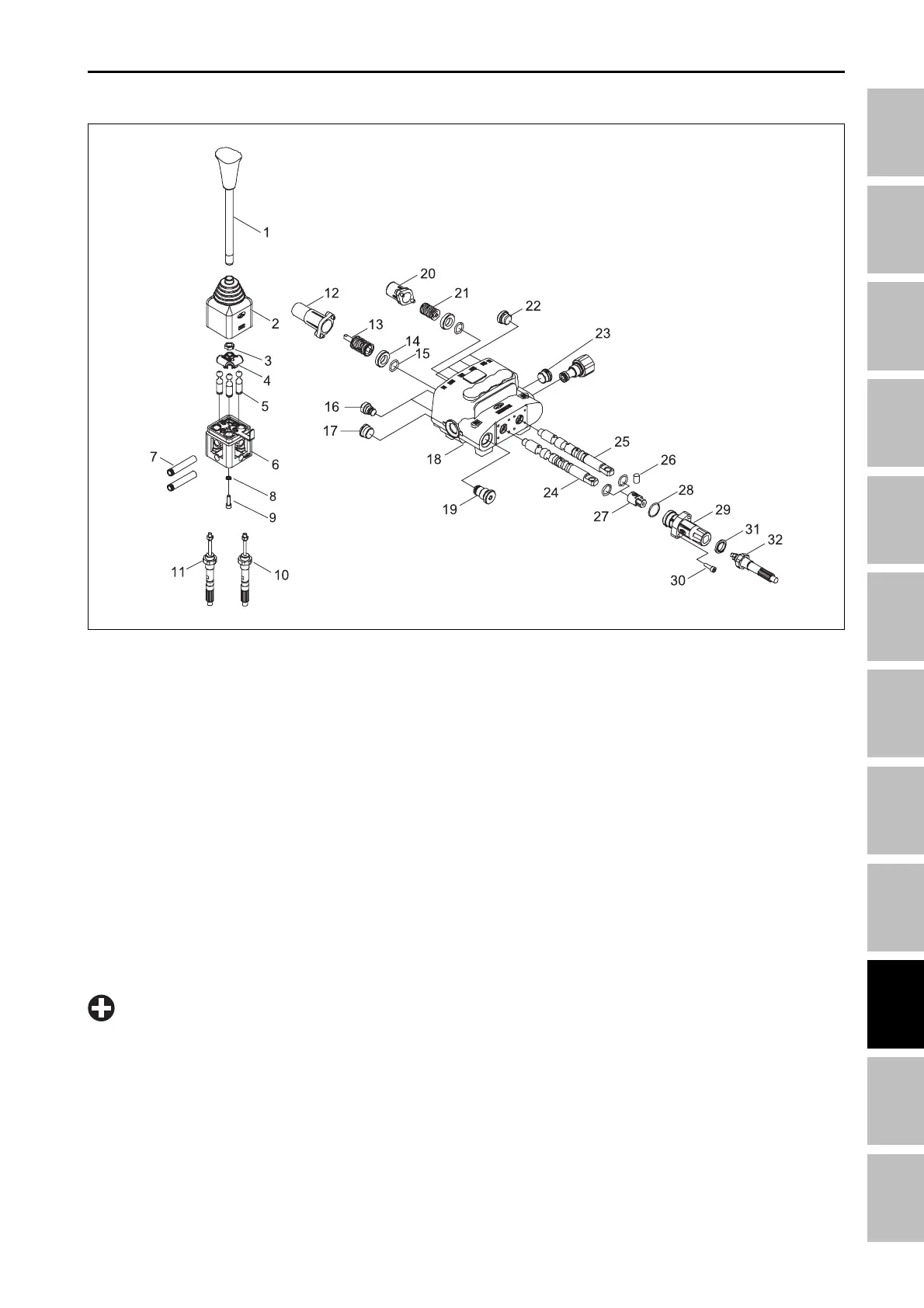

The float spool (24) and spool (25) are not inter-

changeable and will only work in their respective

bores.

Ensure that the spools are inserted into the proper

bores during reassembly.

IMPORTANT

(1) Lever knob

(2) Rubber

(3) Nut

(4) Selector

(5) Pin

(6) Body

(7) Ring

(8) Washer

(9) Screw

(10) Cable

(11) Cable

(12) End cap

196W944B

(13) Spool control kit

(14) Ring

(15) O-ring

(16) Plug

(17) Plug

(18) Body

(19) Plug

(20) End cap

(21) Spool control kit

(22) Plug

4.2.2 JOY-STICK VALVE DISASSEMBLY

5. Disassemble the spool (25) in the same manner

as the float spool using step through 4.

6. Remove the load check plugs (17) with O-rings,

springs and load check poppets from the check

valve ports.

Inspection:

1. Inspect the spools and the spool bores for pitting,

scratches, of excess wear. If found defective, re-

place the Joy-stick valve assembly.

2. Check that the spool moves freely in the spool bore.

3. Inspect the load check valve poppets for pitting or

scratches.

4. Inspect all springs for distortion. Replace if found

to be defective.

5. Replace all O-rings and seals during reassembly

and lightly lubricate with petroleum jelly.

1. Loosen the nuts (32) of cable and remove the

screws (30), rod pins (26) and cables (11, 10).

2. Remove End cap screws, End cap (12) from the

float spool (24).

3. Remove End cap screws, End cap (20) from the

spool (25).

4. Gently slide the float spool (24) with spool control kit

(13), Ring (14) and O-ring (15) out of the valve body.

(23) Plug

(24) Spool

(25) Spool

(26) Red pin

(27) Joint

(28) O-ring

(29) Flange

(30) Screw

(31) Washer

(32) Nut

HYDRAULIC SYSTME - SERVICING

Loading...

Loading...