10-12

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

HSTHST

HSTHST

HST

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

CK22/CK22H

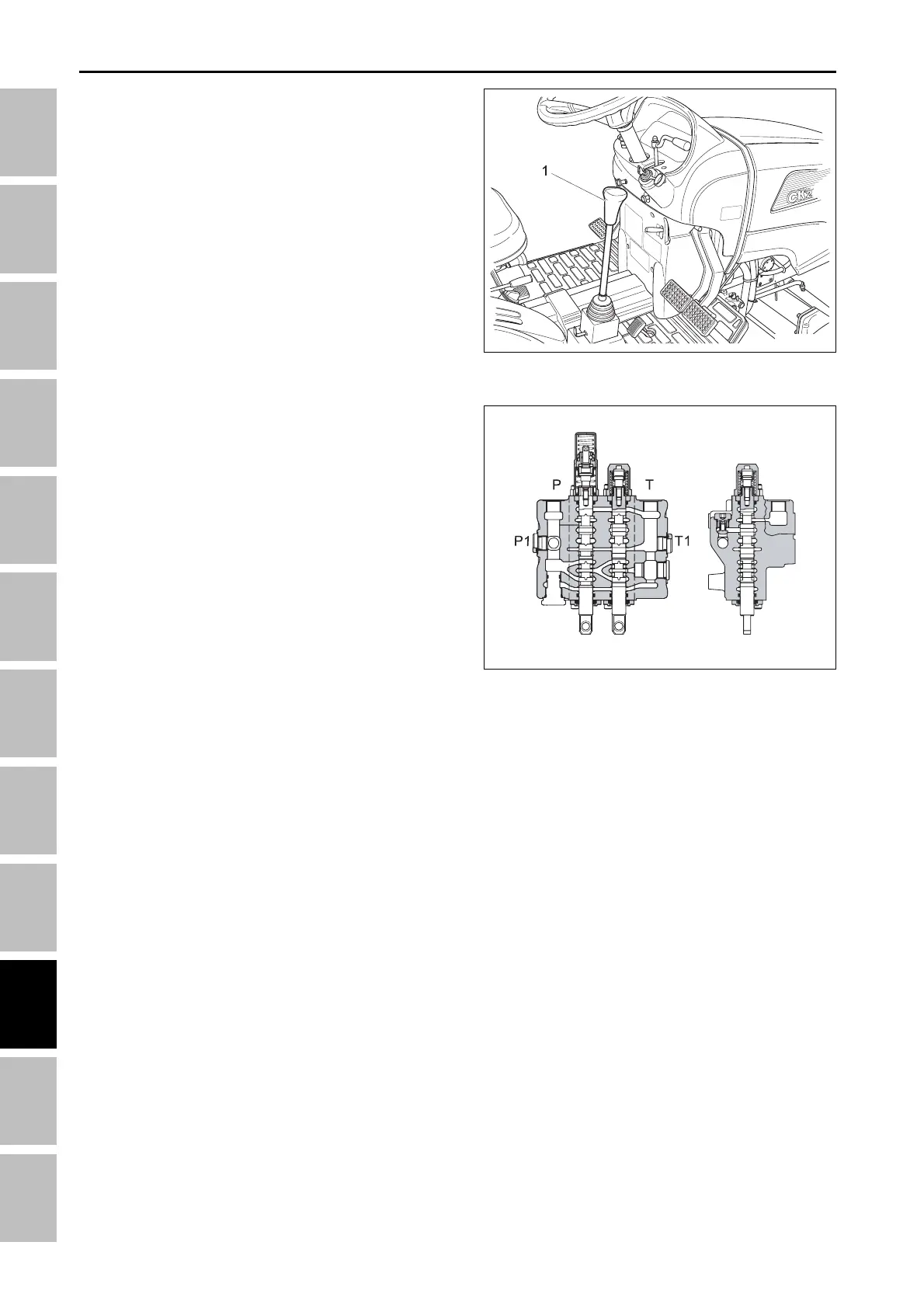

The double-spool remote valve also contains a spring-

loaded detent mechanism to provide a float position

for loader operation. In float position, fluid is free to

flow between piston and rod sides or the loader lift

cylinder allowing the lift arms to float over uneven terrain.

The double-spool remote control valve contains check

valves located in the valve spool passages. The check

valves function to hold the loader lift and bucket cylin-

ders in a fixed position while the valve is being initially

operated to prevent dropping the load. In operation, the

check valve is retained on its seat by spring force plus

the back side pressure of fluid contained in the loader

cylinder. During initial spool movement, pump-pres-

surized fluid fills the passage to the check valve, and

the remaining pump fluid flows to the sump through

the open center passage. With continued spool

movement, the open center passage closes.

Pump pressure increases on the force of the check

valve, overcoming the backside pressure, and causes

the check valve to open. Pump fluid flow then flows to

the cylinder. This action prevents any backflow out of

the cylinder and provides a smooth-lifting action of the

loader.

196W916A

196W918A

2.5.1 DESCRIPTION AND OPERATION

The Joystick valve is mounted on the right fender.

(1) Joystick valve

HYDRAULIC SYSTME - OPERATING PRINCIPLE

Loading...

Loading...