10-40

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

HSTHST

HSTHST

HST

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

CK22/CK22H

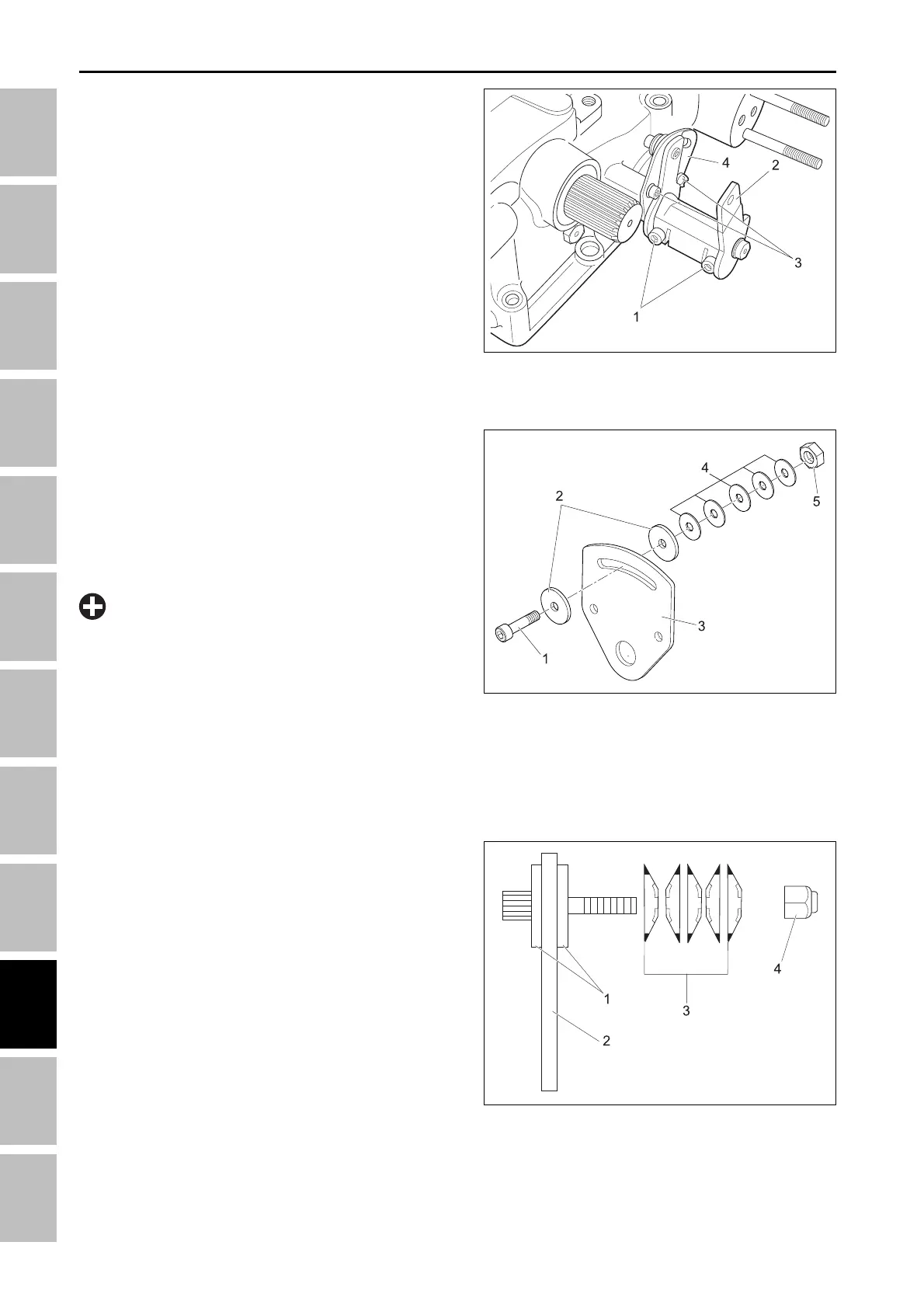

4.5.2 DEPTH CONTROL MECHANISM

REMOVAL

1. Remove lock nut and socket head cap screw (1)

from bracket (2).

2. Remove two socket head cap screw (3) securing

plate to housing. Remove plate (4).

3. Remove bracket from end of eccentric actuator.

196W965A

•

Do not force components during disassembly or

assembly. Clearances are tight and components

must be free to move for depth control mecha-

nism to function correctly.

IMPORTANT

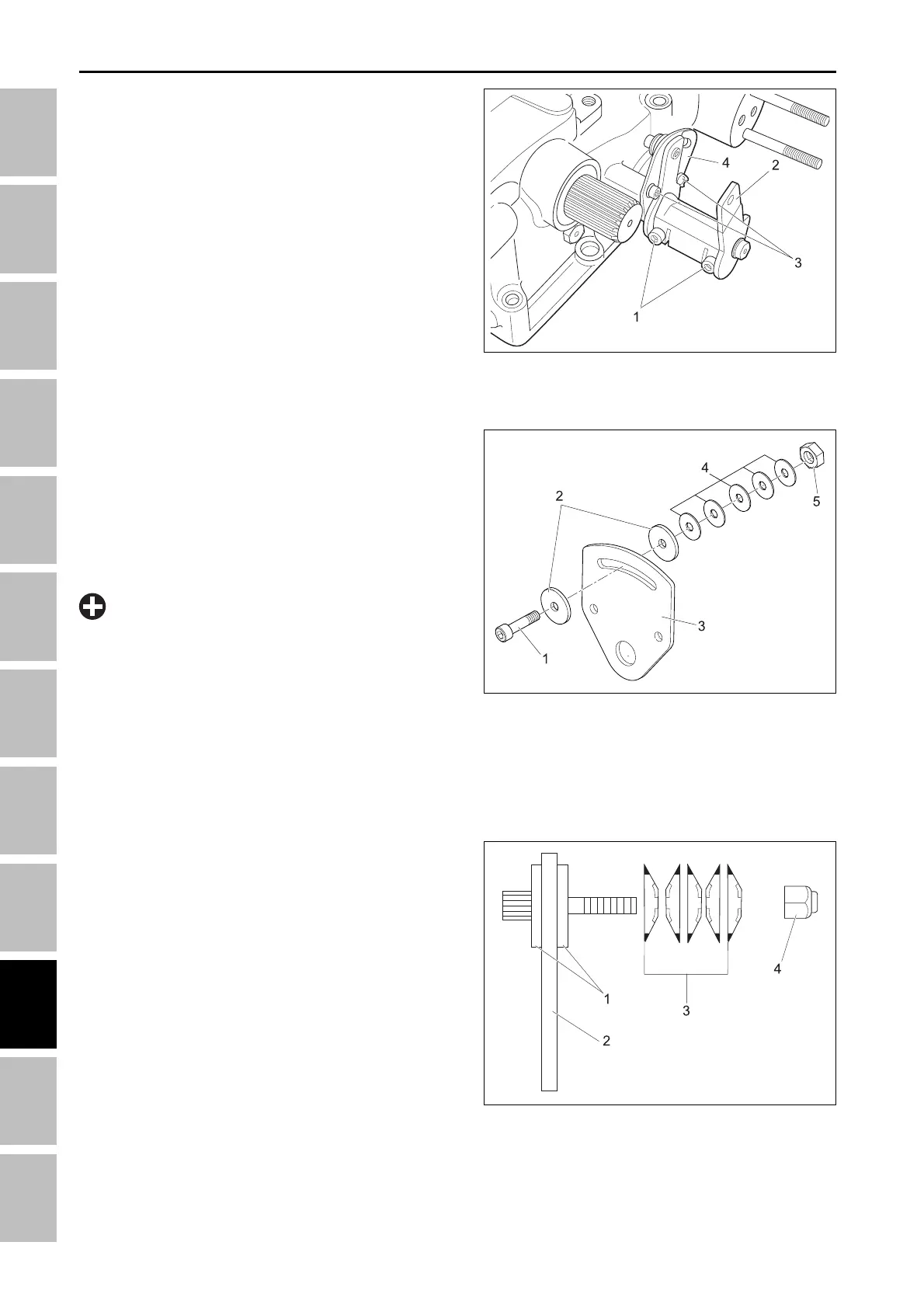

196W966A

(1) Socket head cap screw

(2) Washer

(3) Plate

(4) Belleville washers

(5) Lock Nut

(1) Socket head cap screw (2) Bracket

(3) Socket head cap screw (4) Plate

4. Remove lock nut (5) from end of socket head cap

screw (1).

5. Remove stack of Belleville washers (4) and washer

(2) from socket head cap screw (1).

6. Remove plate (3).

7. Inspect component for wear of damage paying spe-

cial attention to make sure that Belleville washers

are not flattened. Replace as required.

7. When reassembling make sure that Belleville wash-

ers are installed as shown in illustration so they act

like a spring. Tighten Nylock nut until correct friction

is achieved between washers and plate.

196W967A

(1) Washer (3) Belleville washers

(2) Plate (4) Lock Nut

HYDRAULIC SYSTME - SERVICING

Loading...

Loading...