2-71

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

HSTHST

HSTHST

HST

CK22/CK22H

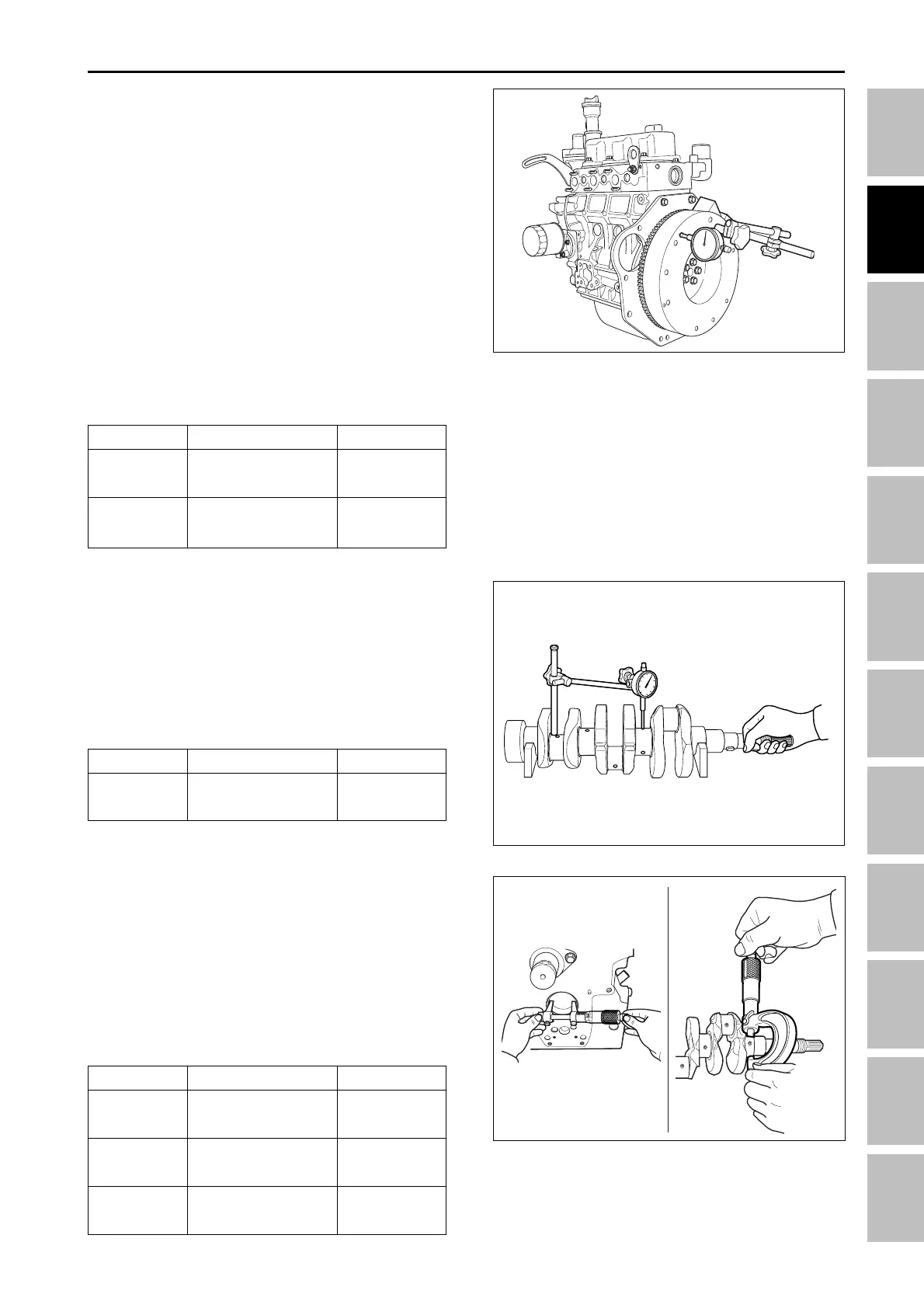

B. CRANKSHAFT ALIGNMENT

1. Support the crankshaft with V blocks on the surface

plate at its front and rear journals and set a dial

indicator with its tip on the intermediate journal.

2. Rotate the crankshaft in the V blocks and get the

misalignment (half of the measurement)

3. If the misalignment exceeds the allowable limit, re-

place the crankshaft.

196W2E6A

Item

Misalignment

Factory spec.

0.02 mm

0.0008 in.

Allowable limit

0.08 mm

0.0031 in.

C. CRANKSHAFT JOURNAL AND BEARING 1

OIL CLEARANCE

1. Measure the I.D. of the crankshaft bearing 1 with an

inside micrometer.

2. Measure the O.D. of the crankshaft journal with an

outside micrometer.

3. If the clearance exceeds the allowable limit, replace

the bearing replacing to Replacing Crankshaft Bear-

ing 1.

196W2E7A

Item

Oil clearance

Journal O.D.

Bearing 1 I.D.

Factory spec.

0.034 ~ 0.092 mm

0.0013 ~ 0.0036 in.

43.934 ~ 43.950 mm

1.7297 ~ 1.7303 in.

43.984 ~ 44.040 mm

1.7317 ~ 1.7339 in.

Allowable limit

0.20 mm

0.0079 in.

-

-

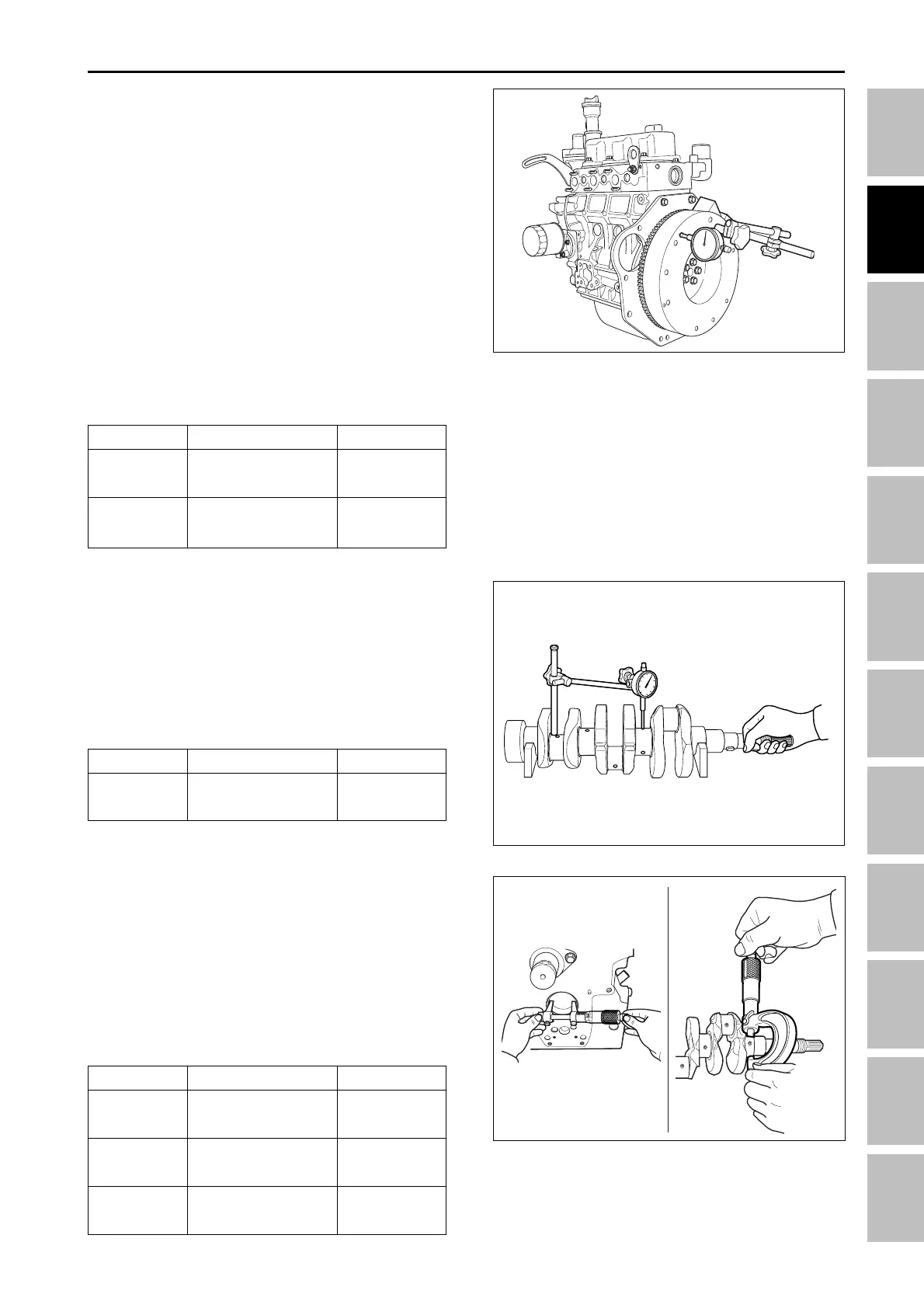

196W2E5B

Item

Deflection

End play

Factory spec.

-

0.15 ~ 0.31 mm

0.0059 ~ 0.0122 in.

Allowable limit

0.05 mm

0.0020 in.

0.5 mm

0.020 in.

7.2.7 CRANKSHAFT

A. FLYWHEEL DEFLECTION AND CRANK-

SHAFT END PLAY

1. Set a dial indicator with its tip on the rear friction

face of the flywheel near the edge.

2. Turn the flywheel and measure the deflection or the

uneven wear.

3. If the measurement exceeds the allowable limit,

remove the flywheel and check the mating faces of

the crankshaft and flywheel.

4. If scored or worn excessively, regrind or replace the

flywheel.

5. Move the crankshaft with flywheel back and forth to

each end and measure the end play.

6. If the play exceeds the allowable limit, replace the

side bearing.

ENGINE - SERVICING

Loading...

Loading...