11-20

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

HSTHST

HSTHST

HST

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

CK22/CK22H

4. SERVICING

4.1 BATTERY

4.1.1 CHECKING

A. BATTERY VOLTAGE

1. Stop the engine and turn off the main key switch.

2. Connect the Voltage meter like figure.

196WA13A

Sect.

Battery voltage

Factory spec.

More than 12 Volt

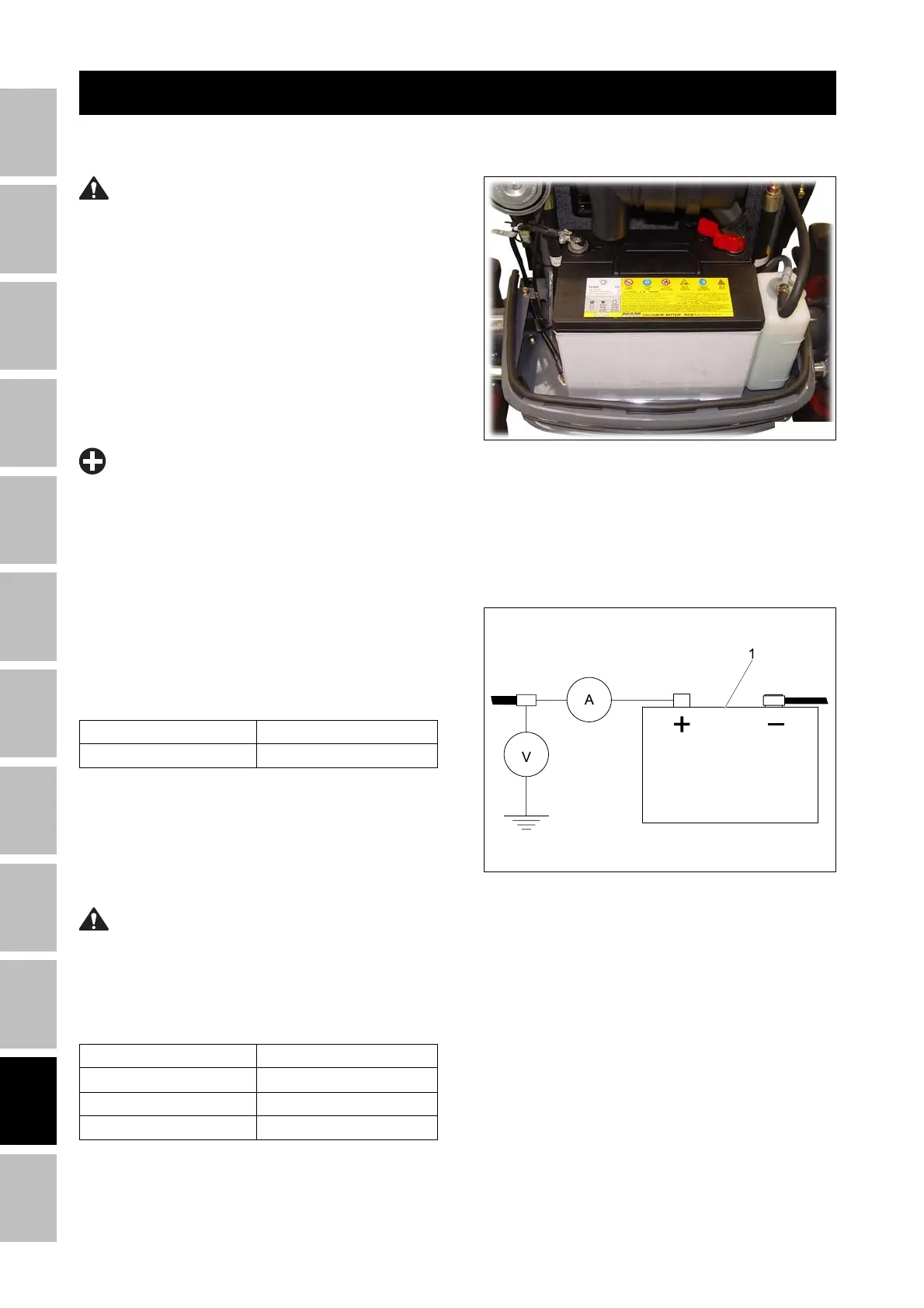

B. CHARGING CURRENT MEASURING

1. Start the engine then detach the positive cord of the

battery.

2. Connect the Ampere meter like figure.

3. Operates all electrical system (like head lights …).

Sect.

Current

Voltage

Engine rpm

Rated spec.

50 A

14 ~ 15 V

2,800 rpm

•

To avoid accidental short circuit, “be sure to at-

tach the positive cable to the positive terminal

before the negative cable is attached to the nega-

tive terminal.

•

Never remove the battery cap while the engine is

running.

•

Keep electrolyte away from eyes, hands and

clothes. If you are spattered with it, wash affected

areas thoroughly with water immediately.

•

Keep open sparks and flames away from the bat-

tery at all times. Hydrogen gas mixed with oxy-

gen becomes very explosive.

CAUTION

•

Operating machine without a properly installed,

adequately sized battery may cause alternator

failure.

IMPORTANT

•

Must connect the Ampere meter after engine is

started.

•

If electric load applied (lights, etc.) is not enough

or battery is fully charged, you can not get the

following results.

CAUTION

(1) Battery

(A) Ampmeter (V) Voltmeter

196WA60A

ELECTRIC SYSTEM - SERVICING

Loading...

Loading...