2-25

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

HSTHST

HSTHST

HST

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

CK22/CK22H

de

D

D

f

Stop

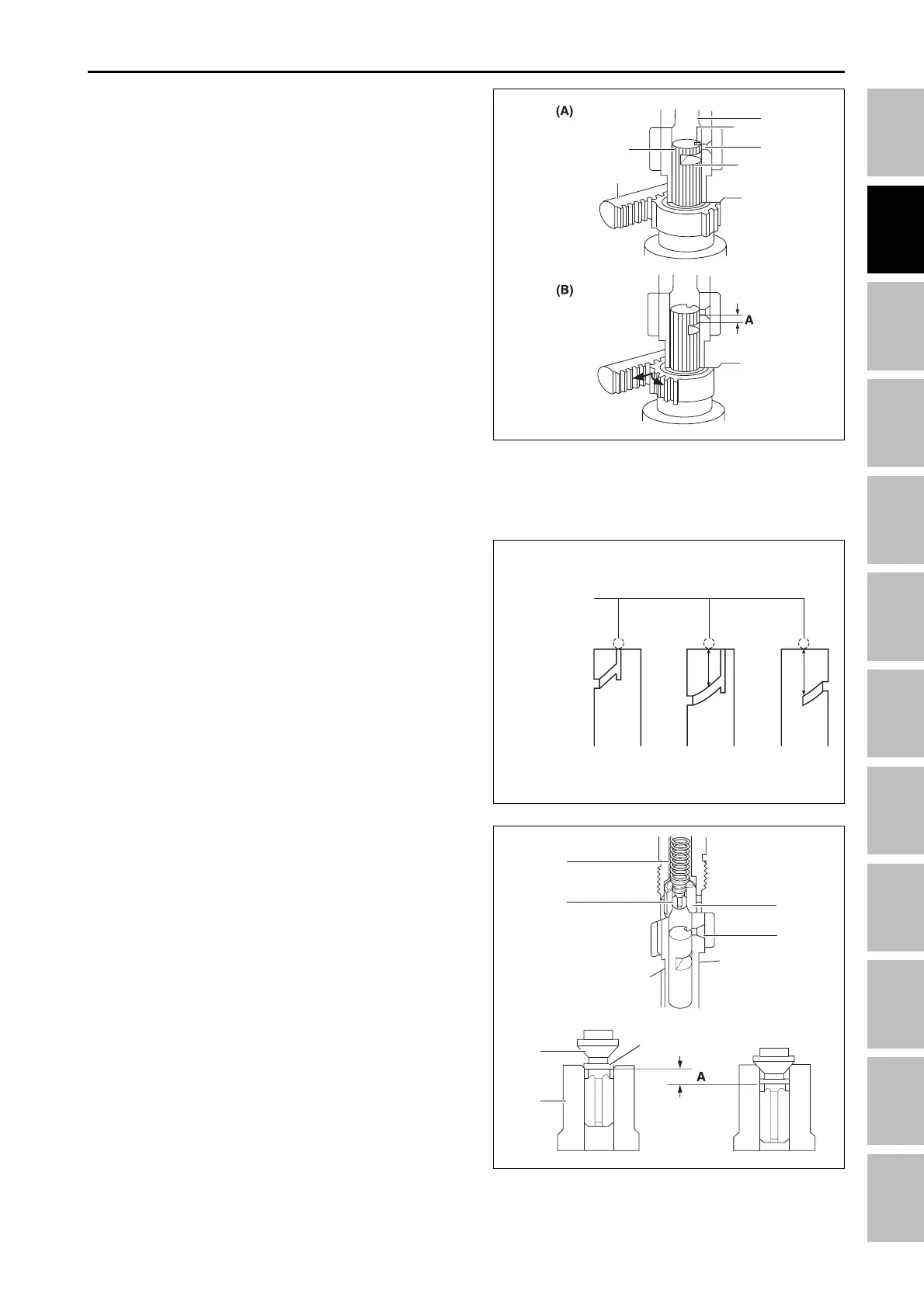

b. Fuel delivery

The plunger is rotated by the control rack and the feed

hole is not aligned with the lengthwise slot. When the

plunger is pushed up, the feed hole is closed by the

plunger. The pressure in the delivery chamber builds

up and forces the fuel to the injection nozzle until the

control groove (6) meets the feed hole. The amount of

the fuel to be forced into the nozzle corresponds to

distance A. In the above figure, the amount of injected

fuel in (c) is larger than the amount of injected fuel in

(b).

T46W240A

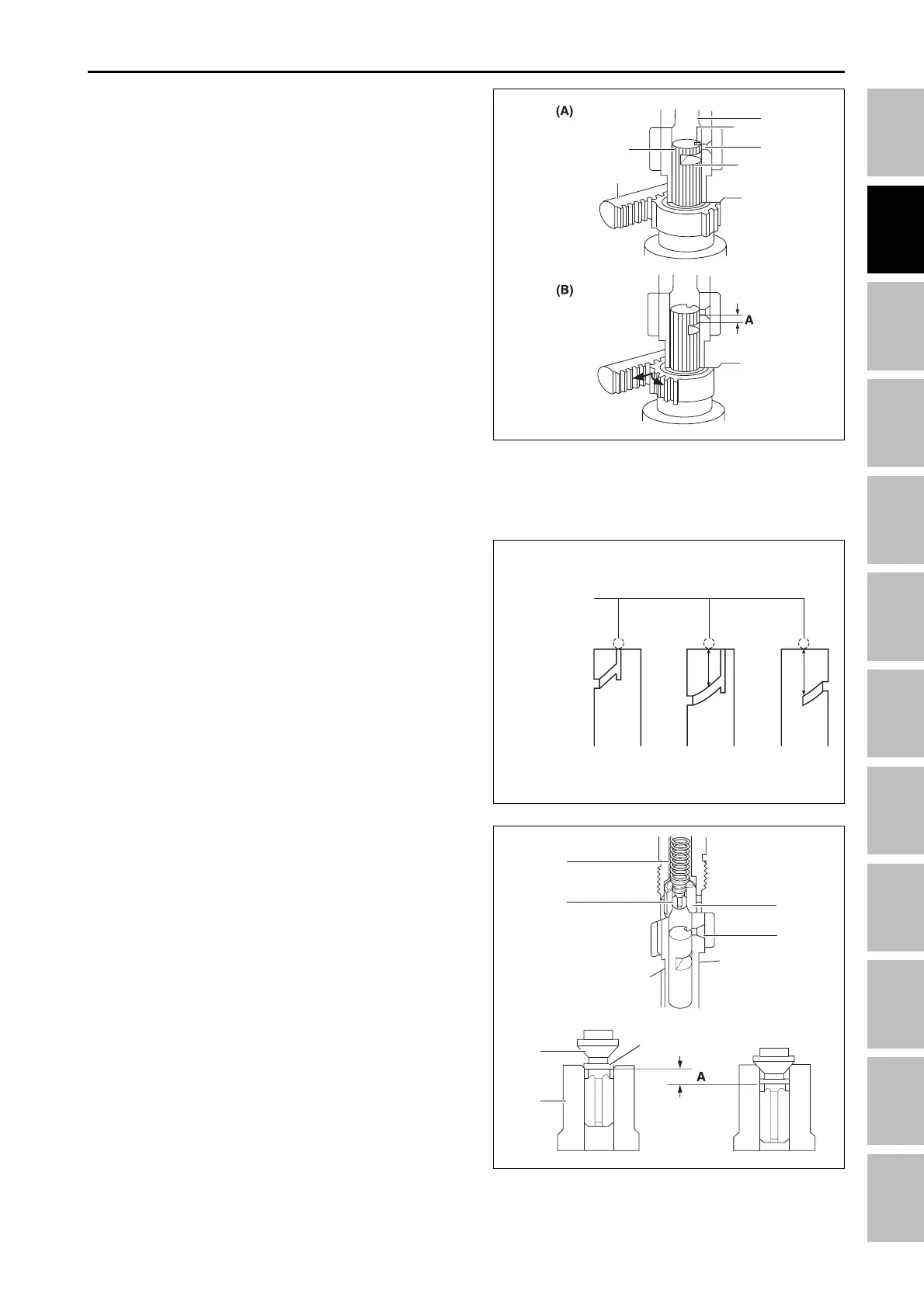

(1) Valve spring (4) Fuel chamber

(2) Delivery valve (5) Valve face

(3) Valve seal (6) Relief plunger

D. DELIVERY VALVE

The delivery valve (2) prevents the fuel in the injection

pipe from flowing back into the delivery chamber and

the fuel in the injection nozzle from dribbling after

injection.

The relief plunger (6) sucks the fuel back from the in-

jection pipe to prevent the leakage dribbling and un-

necessary subsequent injection after the major

injection.

The stroke of A corresponds to the amount of fuel sucked

back (35 mm

3

).

T46W241A

C. AMOUNT OF FUEL DELIVERY

a. No fuel delivery

When the control rack (3) is at the engine stop position,

the lengthwise slot (1) on the plunger (2) aligns with

the feed hole (5). The pressure in the delivery chamber

does not build up and no fuel is forced to the injection

nozzle since the delivery chamber (4) is opened to the

feed hole during the entire stroke of the plunger.

(1) Slot (4) Delivery chamber

(2) Plunger (5) Feed hole

(3) Control rack (6) Control groove

T46W239A

4

5

6

2

3

1

Location of fuel

supply hole

Low speed High speed

3

4

1

5

3

2

6

ENGINE - OPERATING PRINCIPLE

Loading...

Loading...