2-45

DS35-W00 May. 2007

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

TRANSMISSIONTRANSMISSION

TRANSMISSIONTRANSMISSION

TRANSMISSION

ENGINEENGINE

ENGINEENGINE

ENGINE

FRONT AXLEFRONT AXLE

FRONT AXLEFRONT AXLE

FRONT AXLE

STEERINGSTEERING

STEERINGSTEERING

STEERING

BARKEBARKE

BARKEBARKE

BARKE

ELECTRICELECTRIC

ELECTRICELECTRIC

ELECTRIC

INDEXINDEX

INDEXINDEX

INDEX

HYDRAULICHYDRAULIC

HYDRAULICHYDRAULIC

HYDRAULIC

GENERALGENERAL

GENERALGENERAL

GENERAL

REAR AXLEREAR AXLE

REAR AXLEREAR AXLE

REAR AXLE

HSTHST

HSTHST

HST

CK22/CK22H

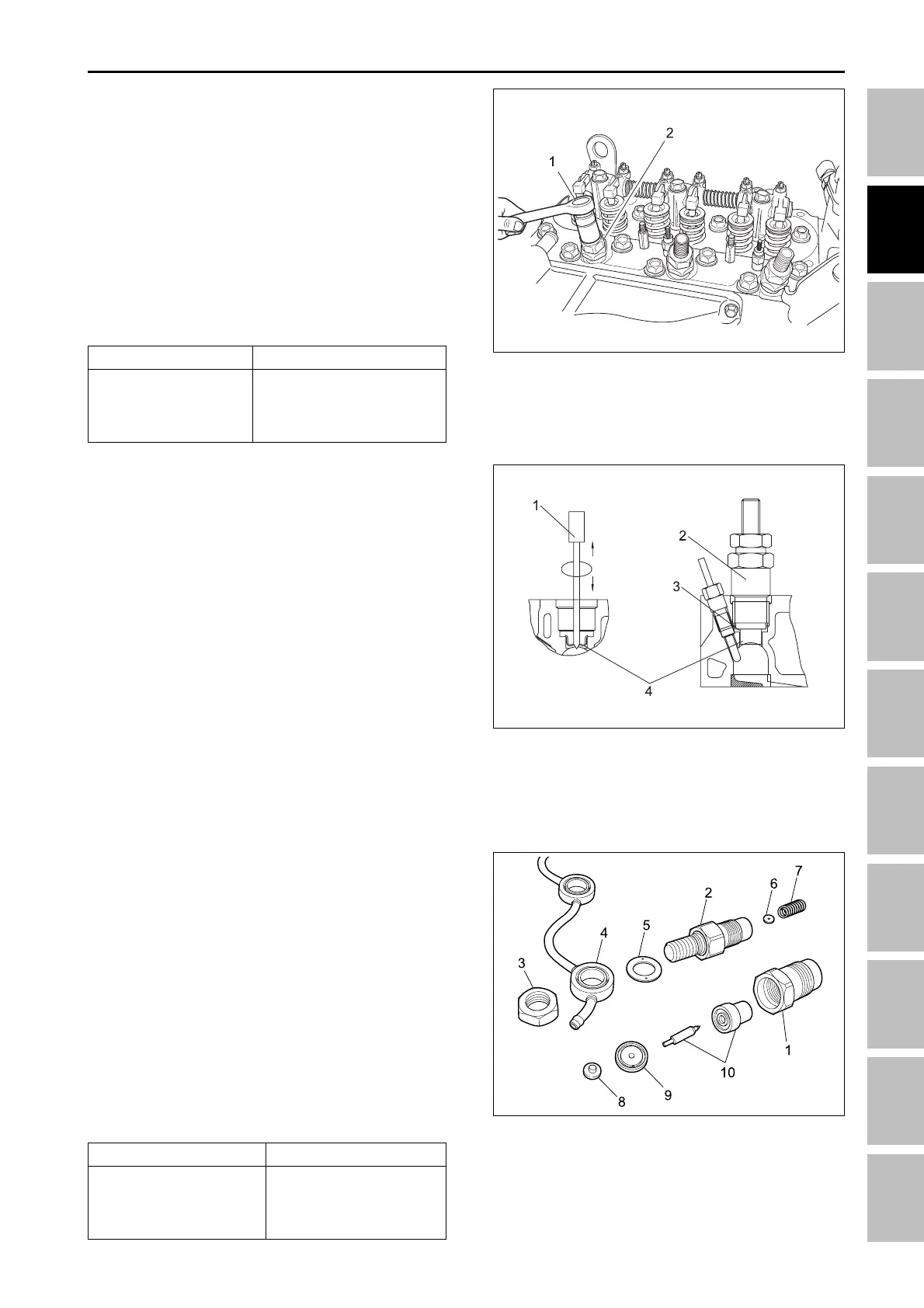

C. REMOVING NOZZLE HOLDER ASSEMBLIES

1. Remove the pipe clips holding the fuel overflow

pipes, and detach the pipes.

2. Detach the nozzle holders using a 27 mm (1.0630 in.)

nozzle holder socket wrench, after loosening the

lock nuts.

3. Detach the copper gaskets on the seats on which

the nozzles are to be installed.

(Note for reassembling)

• Return the nozzle holders after confirming that there

are no metallic particles or foreign matter on the

surface on which the nozzles are to be installed.

(1) Nozzle holder socket wrench

(2) Lock nut

196W257B

Item

Nozzle holder ass’y

Tightening torque

49.0 ~ 68.6 Nm

5.0 ~ 7.0 kgf-m

36.1 ~ 50.6 lb-ft

(1) Plus screw driver

(2) Nozzle

(3) Injection nozzle gasket

(4) Heat seal

196W258B

D. HEAT SEAL ROMOVAL PROCEDURE

1. Drive screw driver lightly into the heat seal hole.

2. Turn screw driver three or four times each way.

3. While turning the screw driver, slowly pull the heat

seal put together with the injection nozzle gasket. If

the heat seal drops, repeat the above procedure.

4. Heat seal and injection nozzle gasket must be

changed when the injection nozzle is removed for

cleaning or for service.

NOTE:

• Use a plus screw driver that has a diameter which is

bigger than the geat seal hole 1/4 in (approx. 6 mm)

196W268A

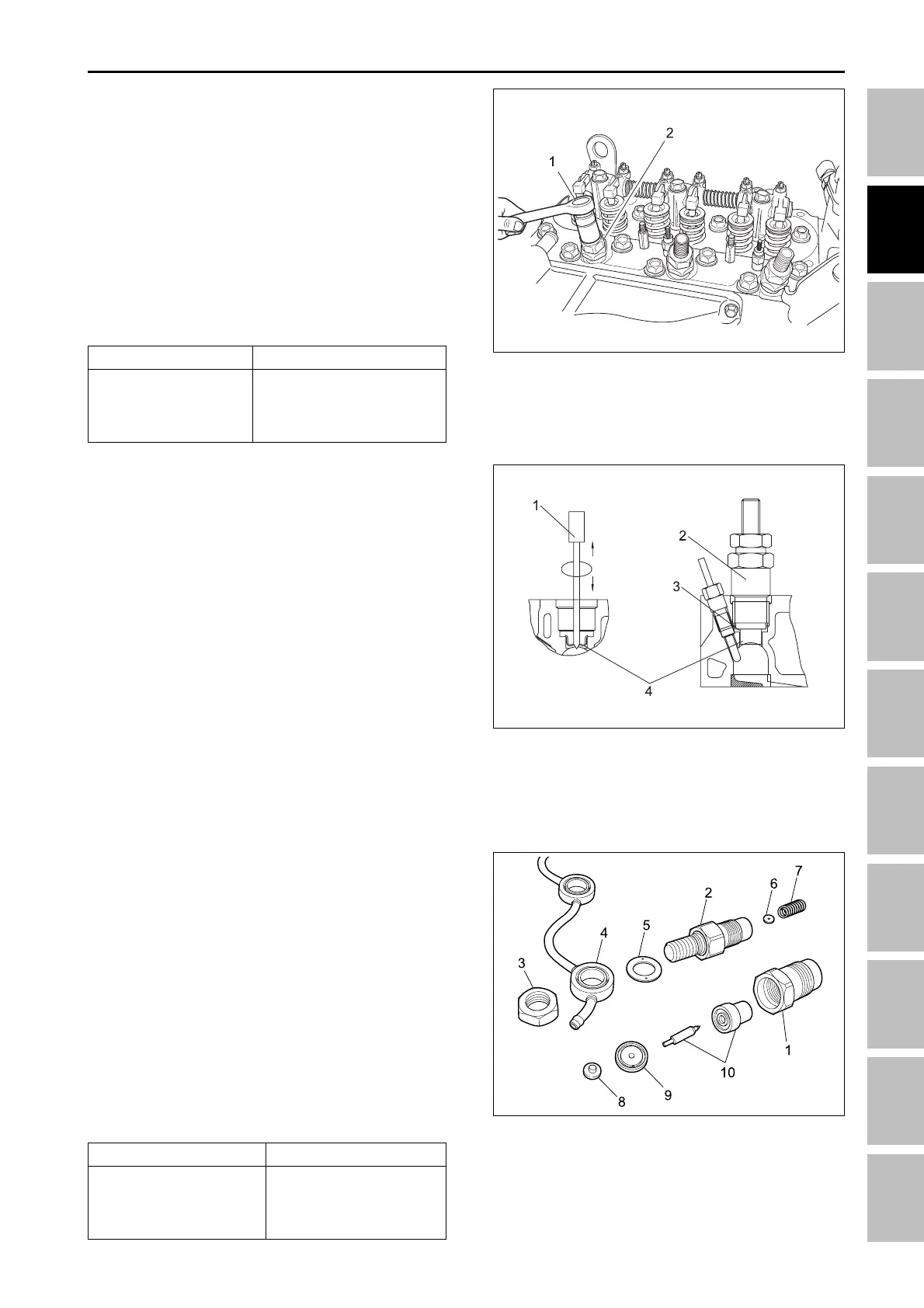

E. NOZZLE HOLDER

ff

ff

f DISASSEMBLING NOZZLE HOLDER

1. Secure the retaining nut with a vise.

2. Remove the nut, the over flow pipe Ass’y and the

plain washer.

3. Remove the nozzle holder body and take out parts inside.

(Note for reassembling)

• When disassembling and reassembling the nozzle

piece dip it in clean fuel.

• Install the push rod, noting its direction(upside down).

• Do not tighten it too much, or the needle valve will

not slide easily and the injection performance will

be decreased.

(1) Retaining nut (6) Adjusting washer

(2) Nozzle holder body (7) Nozzle spring

(3) Nut (8) Push rod

(4) Over flow pipe ass’y (9) Distance piece

(5) Gasket (10) Nozzle piece

Item

Retaining nut

Tightening torque

29.4 ~ 49.0 Nm

3 ~ 5 kgf-m

21.7 ~ 36.1 lb-ft

ENGINE - SERVICING

Loading...

Loading...