OPERATION

7. Fully lower the combine feeder house adapter should

be fully separated from the header).

NOTE:

You m ay need to

hold the header down switch

for a few secon

ds to ensure the feeder house is

fully lowered

.

8. Read vo lta g e

.

9. Raise header

so cutterbar is 6 in. (150 mm) off

the ground.

10. Read voltag

e.

11. Adjust the v

oltage limits (refer to Adjusting Voltage

Limits, pag

e93) if the sensor voltage is not within the

low and hig

h limits or if the rang e between the low and

high limit

s is insufficient (refer to Table 3.10 Combine

Voltage Li

mits, page 91).

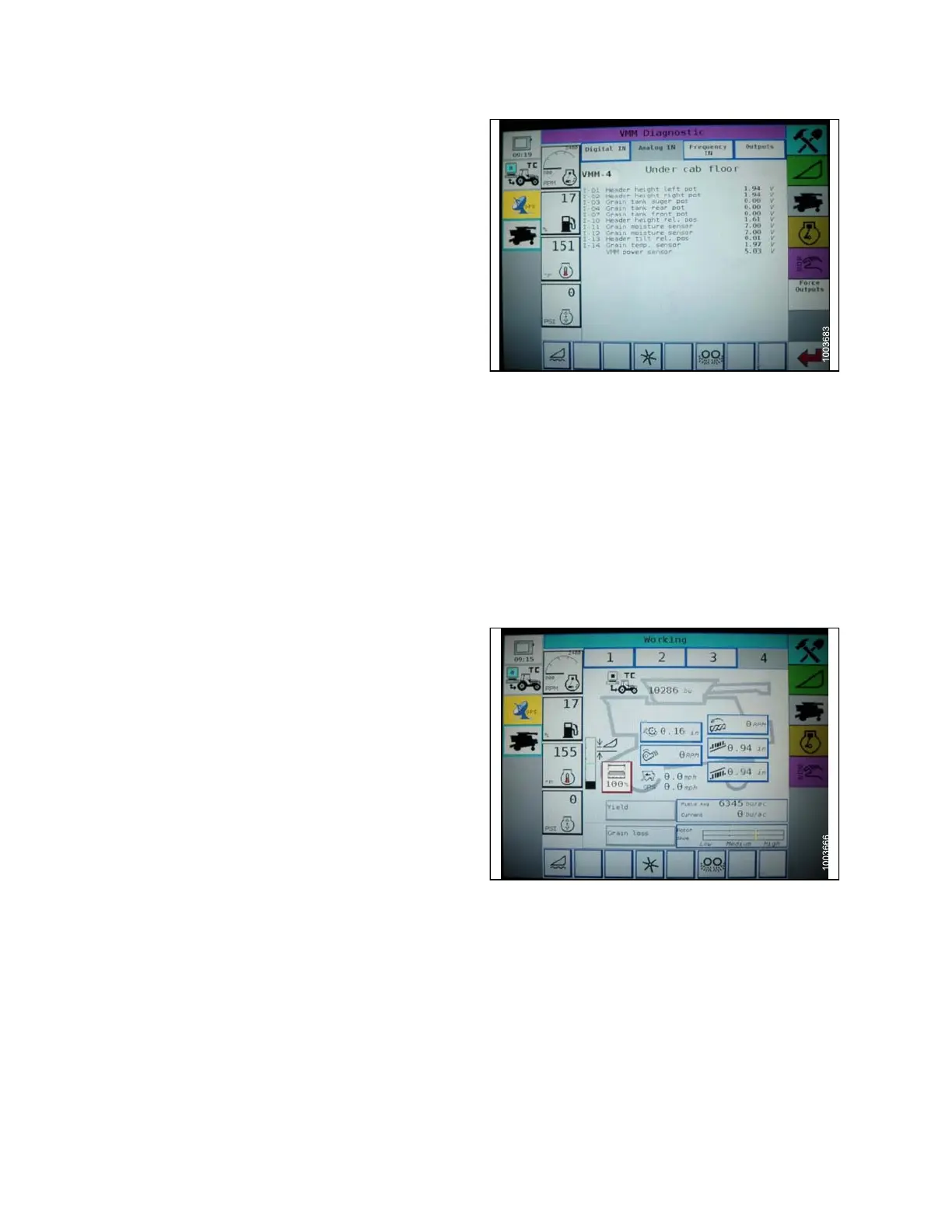

Figure 3.105: Challenger Combine Display

Engaging the Auto Header Height Control ( Ch allenger 6 S eries)

NOTE:

Changes may have

been made to the combine controls or display since this document was published. Refer to

the combine oper

ator’s manual for updates.

The following system components are required in order for the Auto Header Height Control (AHHC) to work:

• Main module (PCB board) and header driver module

(PCB board) mounted in card box in Fuse Panel

Module (FP).

• Multi-Function Control Handle operator inputs.

• Operator inputs mounted in the control console module

(CC) panel.

NOTE:

In addition to the above components, the electro

hydraulic header lift control valve also is an integral part

of the system.

Engage the AH

HC as follows:

1. Scroll thro

ugh the header control options on the

combine dis

play using the header control switch until

the AHHC ico

n is disp layed in the first message box.

The AHHC wil

l adjust the header height in relation

to the groun

d according to the height setting and

sensitivi

ty setting.

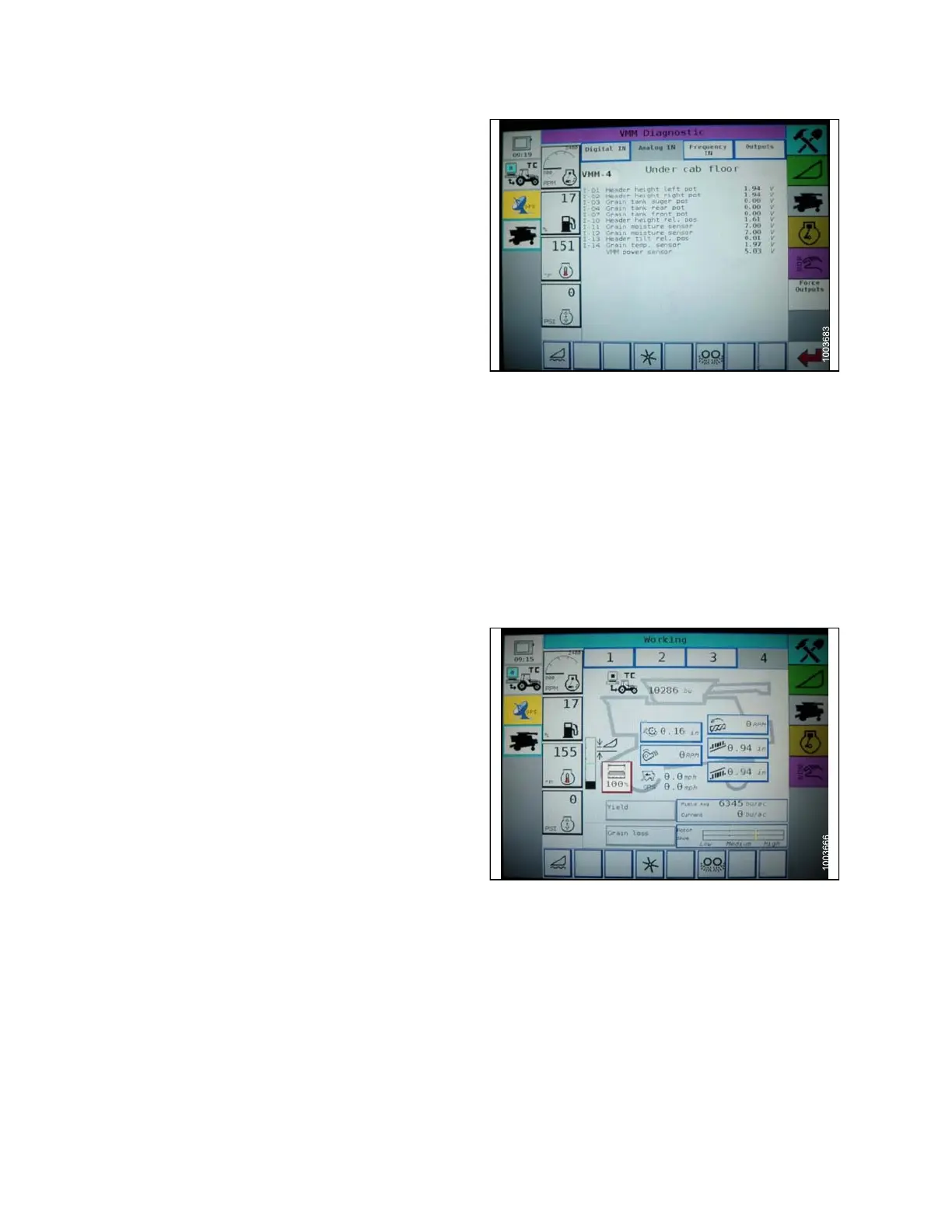

Figure 3.106

: Challenger Combine Display

147695 96 Revision A

Loading...

Loading...