OPERATION

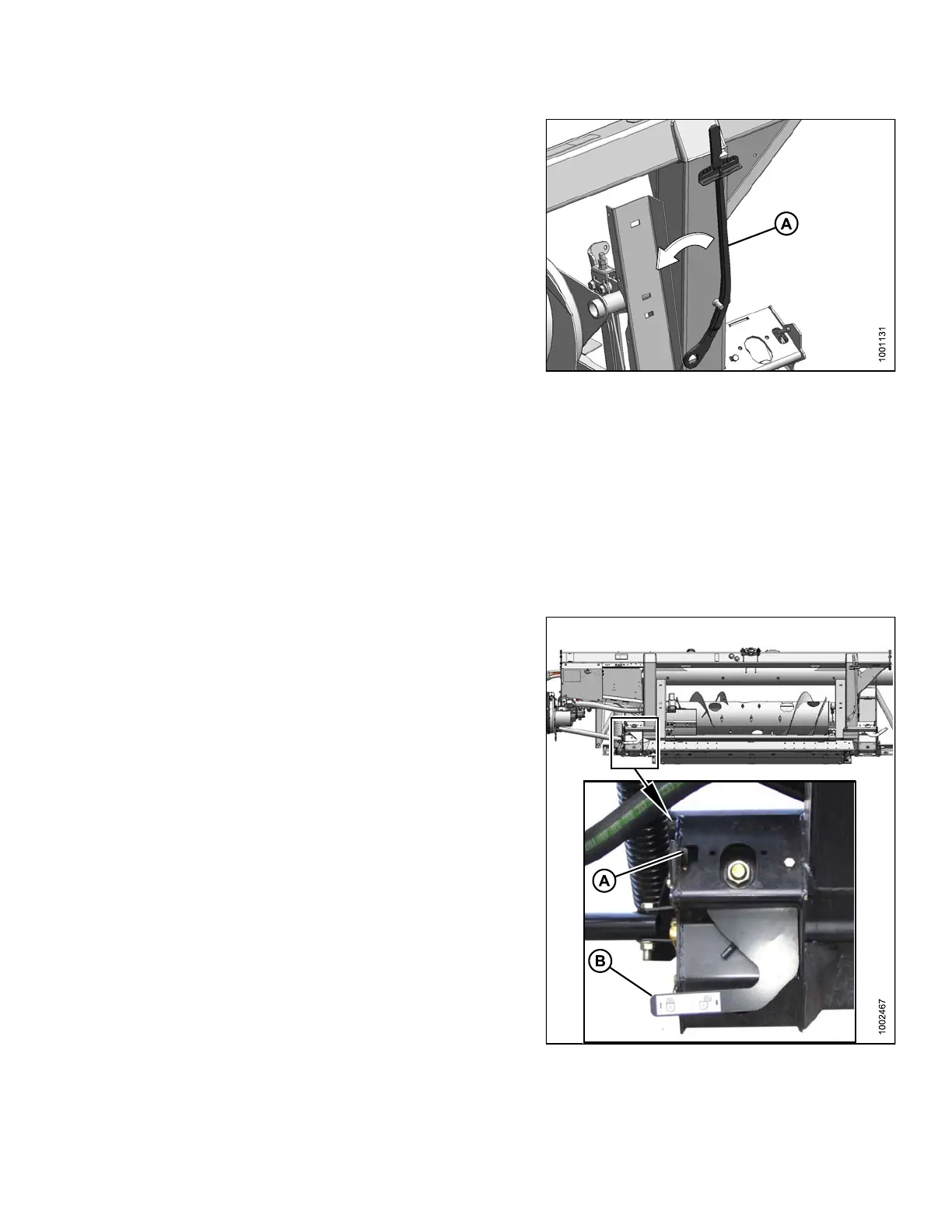

18. Return torque w rench (A) to storage location at

right-hand side of adapter frame.

Figure 3.46: Torque Wrench

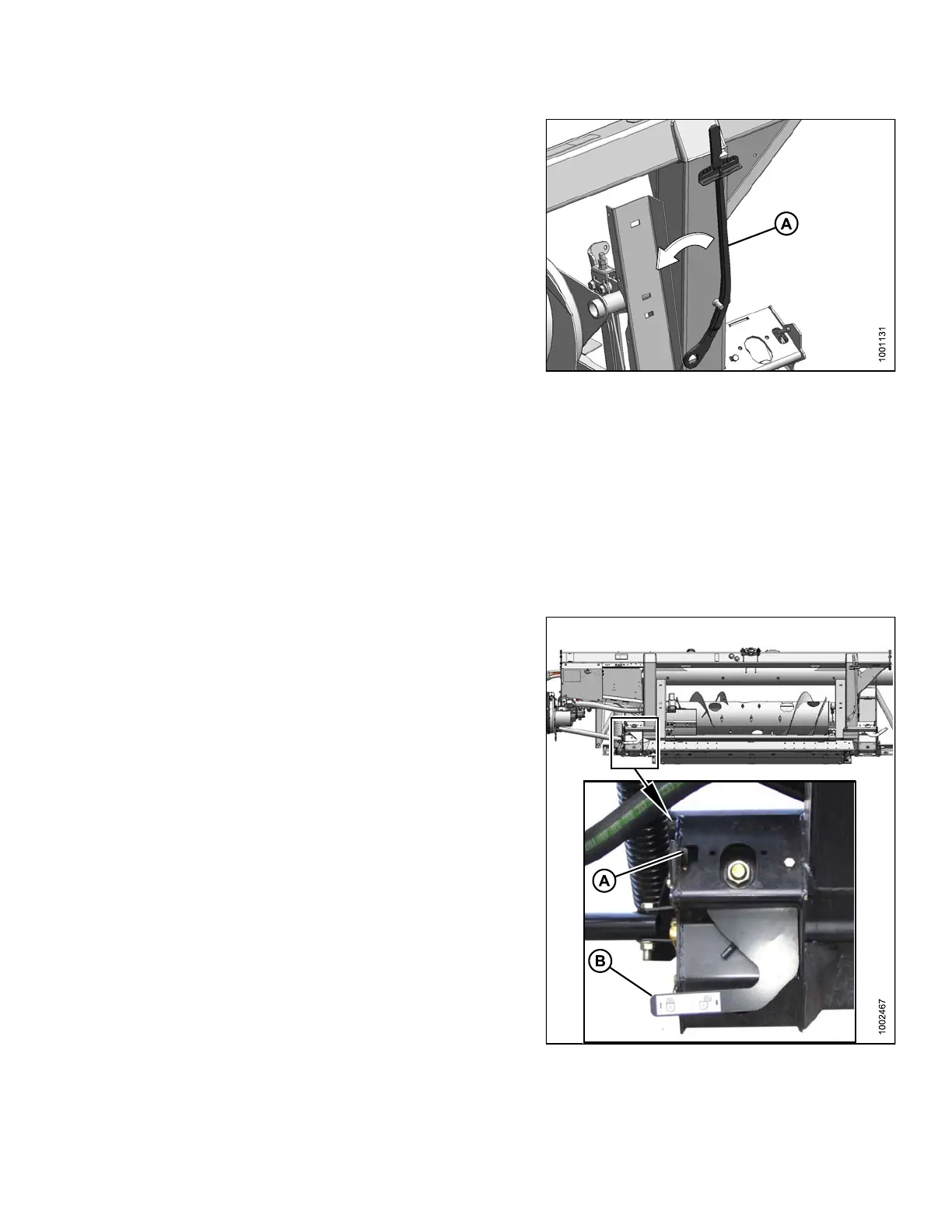

Locking/Unlocking Header Float

The functi

on of the header float locks is to lock and unlock the header float system. There are two locks—one on

each side

of the adapter.

IMPORTAN T:

The float locks must be engaged when the header is being transported with the adapter attached so that there is

no relative movement between the adapter and header during transport. The float locks m ust also be locked

during detachment from the combine to allow the feeder house to release the adapter.

To disengage float locks (unlock), move latch (A)

downward, and move lever (B) at each lock to lowest

position. In this position, the header is unlocked, and can

float with respect to the adapter.

To engage float locks (lock), move lever (B) up to its

highest position. In this position, the header cannot move

with respect to the adapter.

Figure 3.47: Float Lock

147695 63 Revision A

Loading...

Loading...