OPERATION

3.7.2 Header Float

The header fl oa

t system reduces the ground pr essure at the cutterbar and allo ws it to m ore easily follow the

ground and qui

ckly respond to sudden ground contour changes or obstacles.

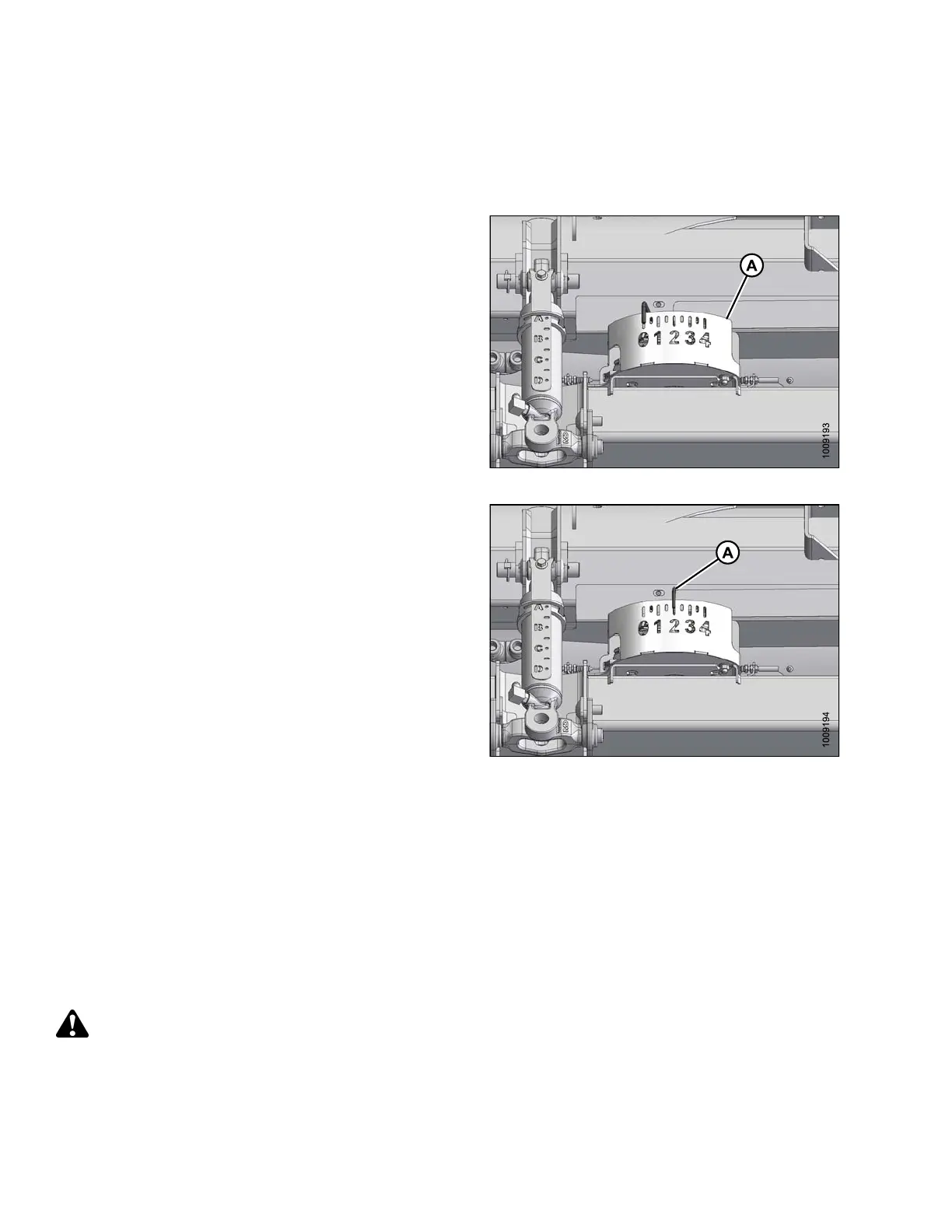

Header float is

indicated on the CA25 float indicator (A) and

the values 0 t

o 4 represent the force of the cutterbar on the

ground, with

‘0’ being the least and ‘4’ th e highest.

The m aximum f

orce is determined by the tension on the

adapter float

springs which are adjustable. The tension

is fa ctory s

et but can be changed to suit field and crop

conditions

. Refer to Checking and Adjusting Header Float,

page 58.

TheFD75com

bine header performs best with minimum

ground pre

ssure, under normal conditions. Readjust the

float if add

ing optional attachments that affect the weight of

the header

.

Figure 3.34: Float Indicator

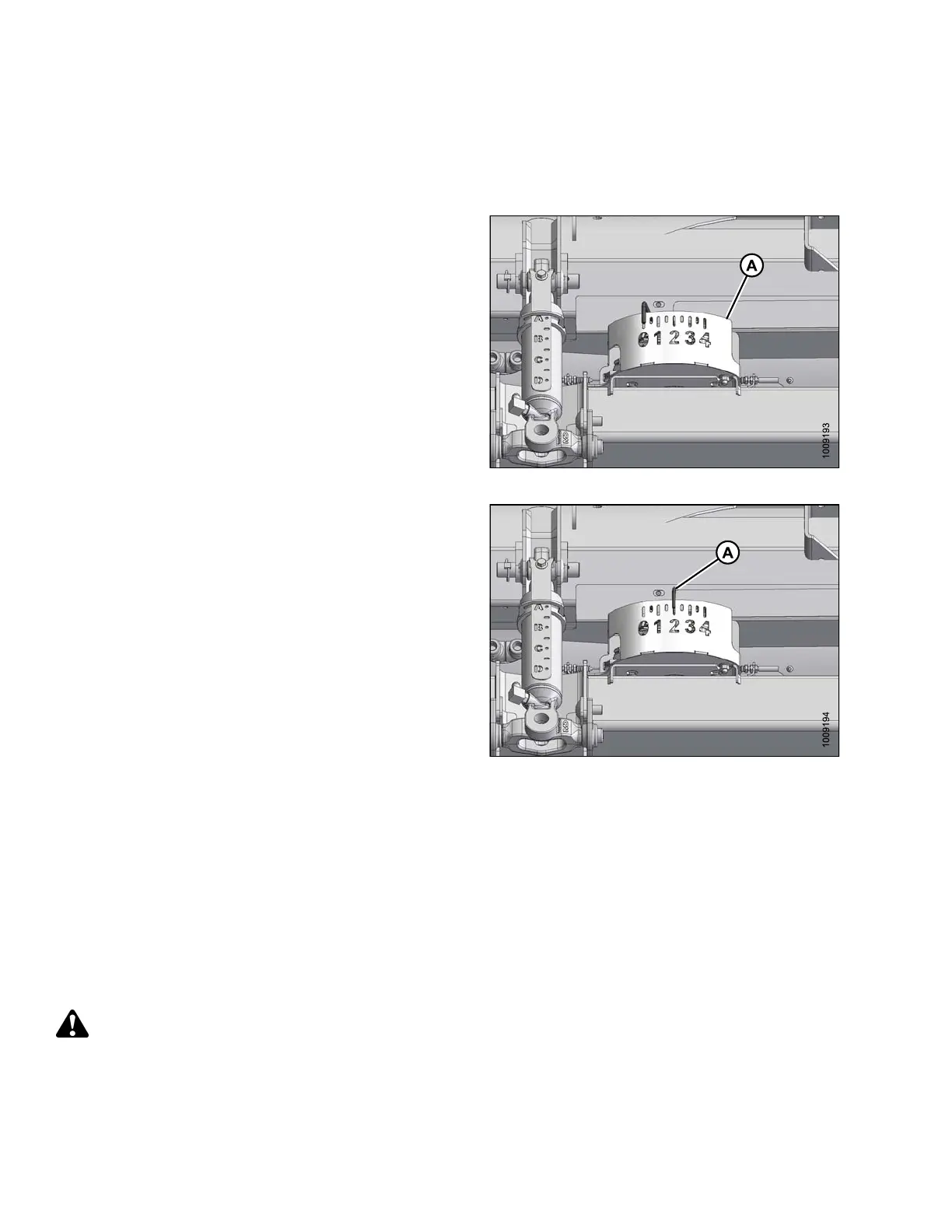

1. To set the

float for cutting on the ground:

a. Ensure th

at the header fl oat locks are disengaged.

Refer to L

ocking/Unlocking Header Float, page 63.

b. Lower fee

der h ouse with combine header controls

until flo

at indicator (A) reaches the desired float

value (c

utterbar ground force). Use “2” initially and

adjust a

ccordingly.

Figure 3.35: Cutting on the Ground

2. To set t

he float for cutting off the ground:

a. Set up

the stabilize r wheels. Refer to Cutting Off

the Gr

ound, page 52.

b. Note t

he float value on the float indicator and

maint

ain this value during operation, disregarding

mino

r fluctuat ions on the indic ator.

Checking a nd Adjusting Header Float

To check and

adjust th e header float, follow these steps:

DANGER

To avoid bodily injury or death from unexpected start-up of machine, always stop engine and remove key

from ignition before leaving operator ’s seat for any reason.

147695 58 Revision A

Loading...

Loading...