OPERATION

Adjusting Endshields

Plastic endshields m ay expand or contract when subjected to large temperature changes. The position of the top

pin and lower catch can be adjusted to compensate for dimensional changes.

To adju st the end shield, perform the follow ing:

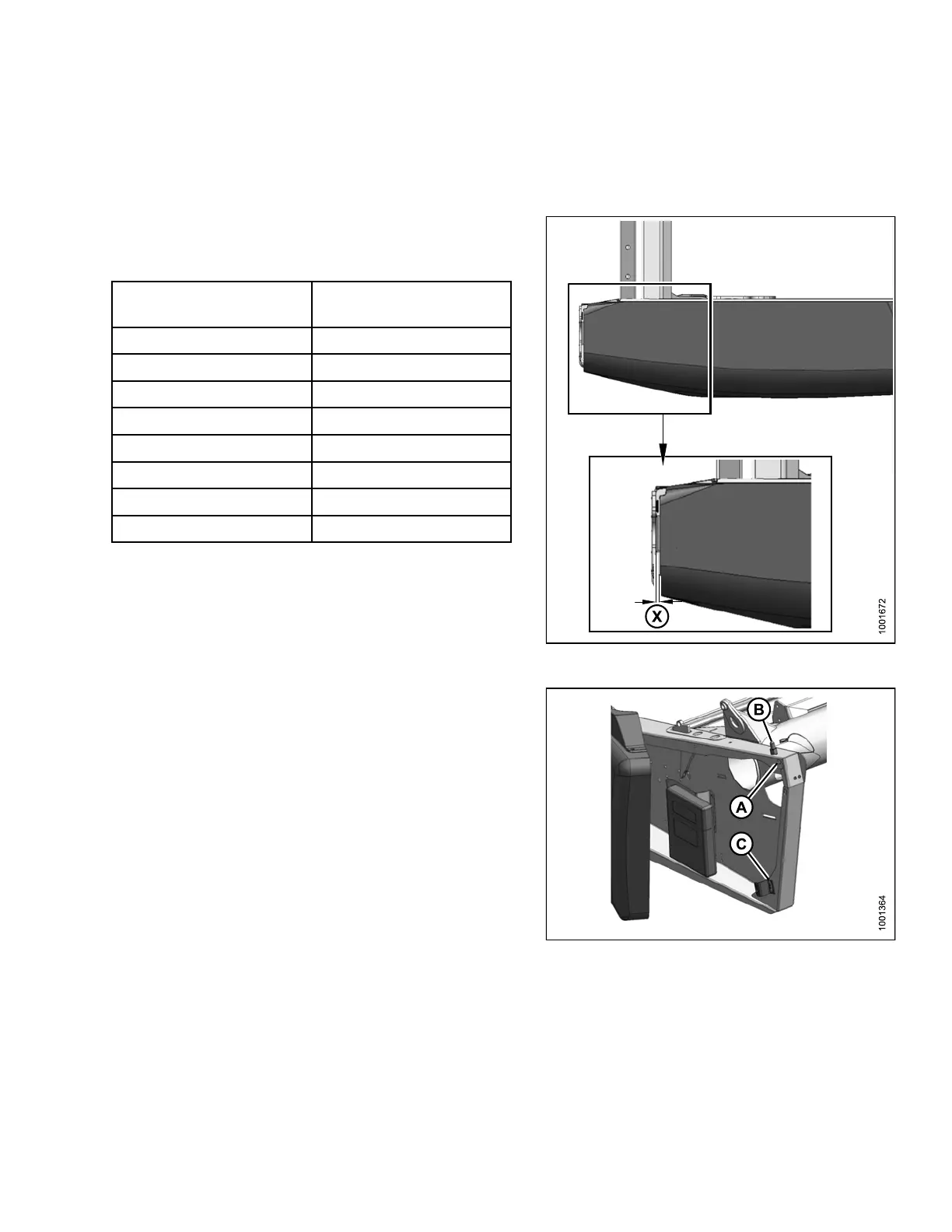

1. Check gap ‘X’ between the front end of shield and

header frame and compare to chart.

Temperature

°F (°C)

Gap ‘X’

in. (mm)

25 (-4) 1-1/8 (28)

45 (7) 1 (24)

65 (18) 13/16 (20)

85 (29) 5/8 (16)

105 (41) 1/2 (12)

125 (52) 5/16 (8)

145 (63

)

3/16 (4

)

165 (89)

0

Figure 3.16: Left-Hand Endshield

If adjustments are required, proceed as follows:

2. Open endshield. Refer to Opening Endshields, page

33.

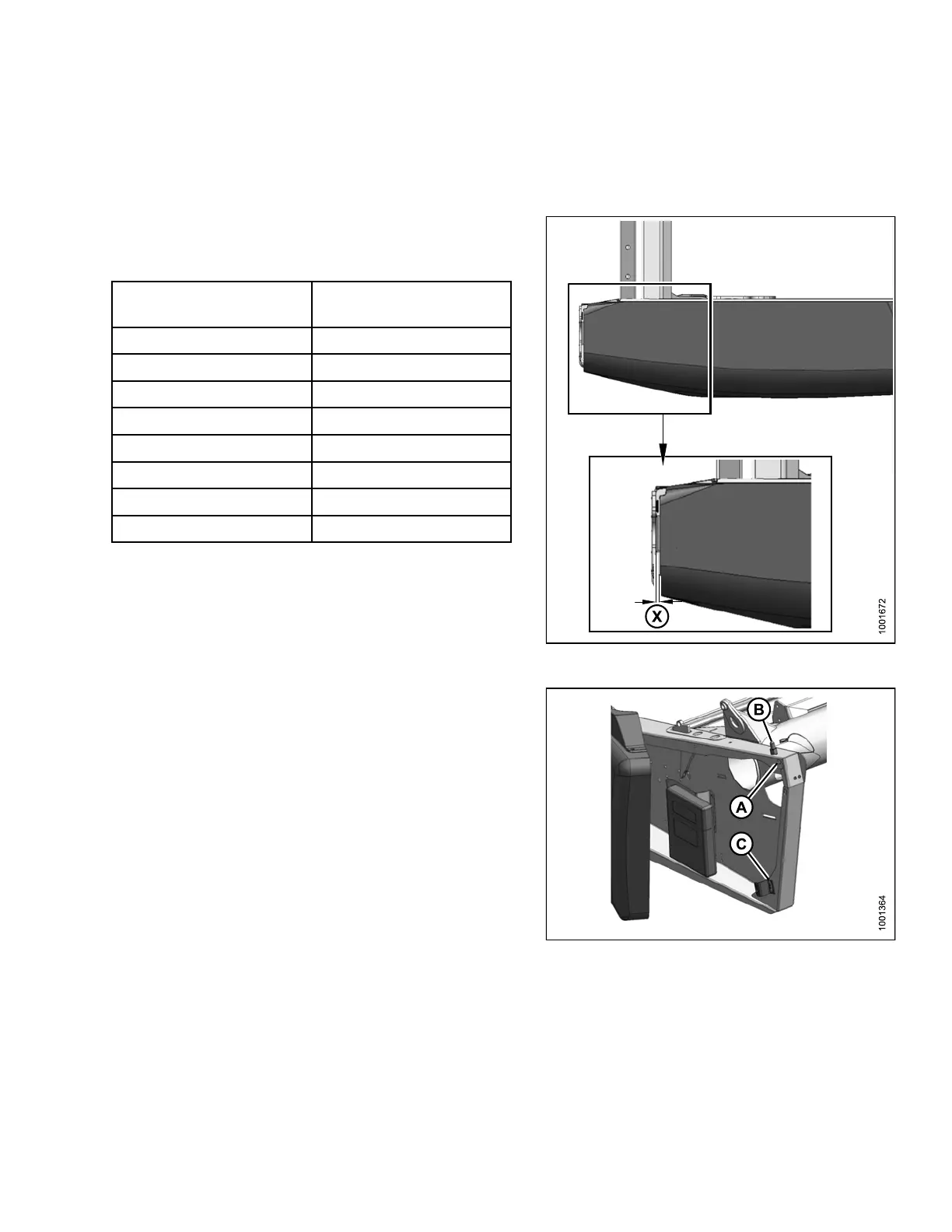

3. From inside endsheet, loosen nut (A) on pin (B) with a

3/4 in. (19 mm) socket.

4. Close endshield and adjust position to achieve

the gap ‘X’ between the front end of shield and

header frame.

5. Open endshield and tighten nut (A).

6. To achieve a snug fit between top of shield and header

frame and to ensure that endshield is fully engaged on

pin (B), loosen bolts on catch (C) and adjust catch as

required to reposition shield.

7. Tighten bolts o n catch (C).

8. Close endshield. Refer to Closing Endshields, page

34.

Figure 3.17: Left-Hand Endshield

147695 37 Revision A

Loading...

Loading...