MAINTENANCE AND SERVICING

Service Intervals

Refer to the illustrations on the following pages to identify the various locations that requ ire lubric ation and

servicing. Illustrations are organized by the frequency of service that is required.

IMPORTANT:

Unless other

wise specified, use High Temperature Extreme Pressure (EP2) Performance with 1% Maximum

Molybdenum D

isulphide (NLGI Grade 2) Lithium Base.

Knife: Except in sandy conditions.

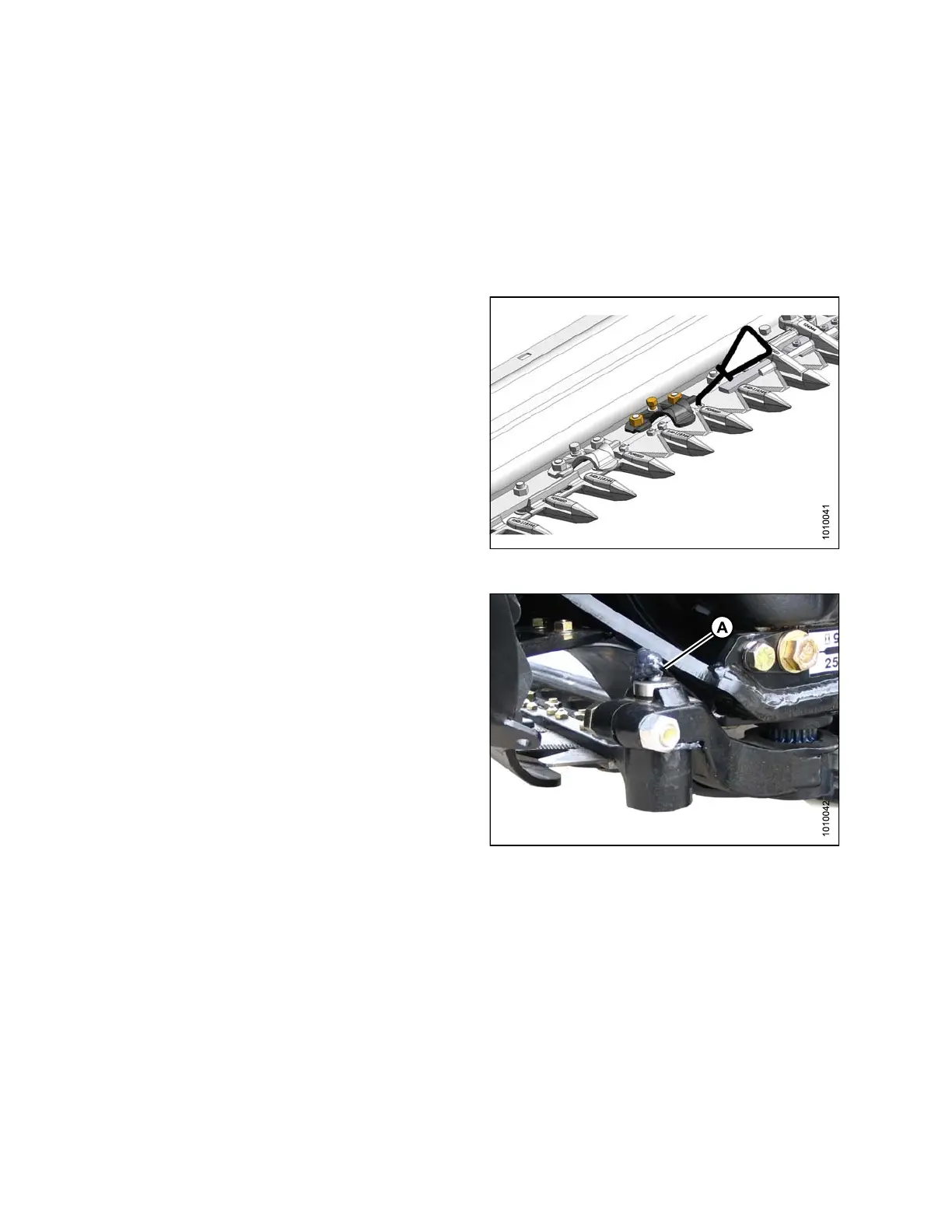

Figure 5.5: Every 10 Hours or Daily

Knifehead:

NOTE:

To preve

nt binding and/or excessive wear caused by

knife pr

essing on guards, do NOT ov er grease the

knifehe

ad (A). Only, one to two pumps with a mechanical

grease

gun (do NOT use an electric grease gun) is

requir

ed. If more than six to eight pumps of the grease

gun are

required to fill the cavity, replace the seal in the

knifeh

ead. Refer to 5.8.3 Removing Knifehead Bearing,

page 30

1

.

NOTE:

Check for signs of excessive heating on first few guards

after greasin g. If required, relieve pressure by pressing

check-ball in grease fitting.

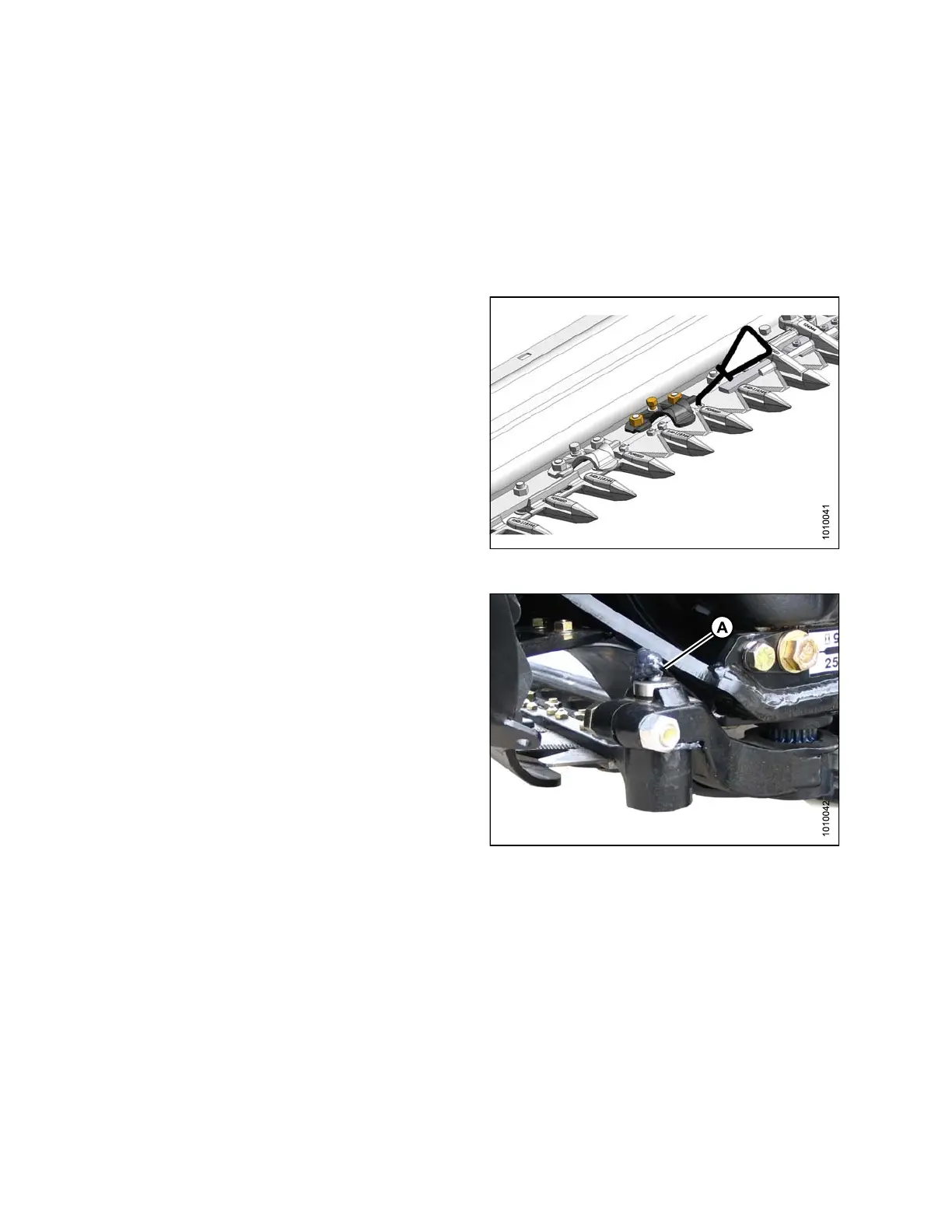

Figur

e 5.6: Every 25 Hours

A - Knifehead (Single Knife [1 Place]; Dou ble Knife - [2 Places])

147695 260 Revision A

Loading...

Loading...