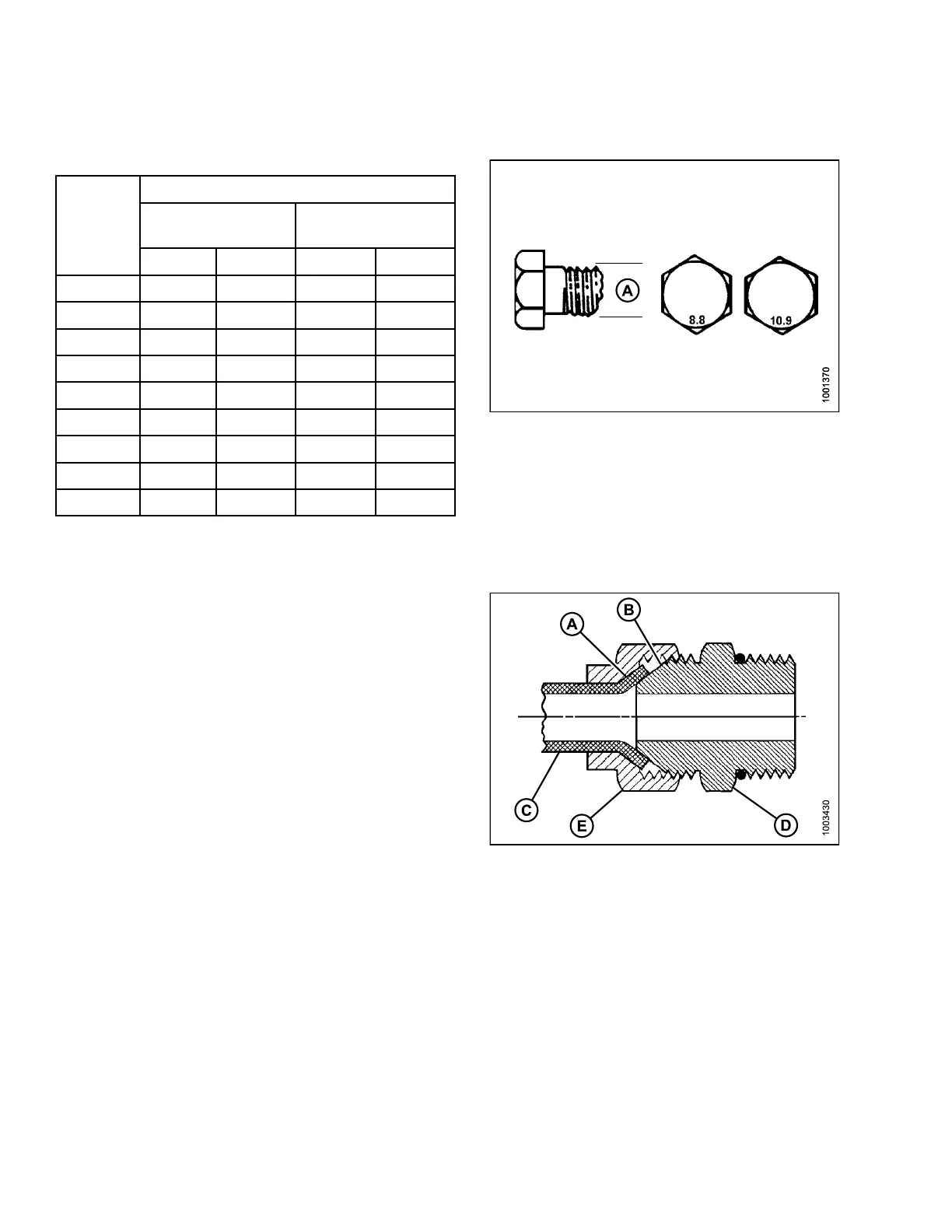

REFERENCE

8.1.3 Metric B

olt Specifications Bolting into Cast Aluminum

Table 8.9 Metric Bolt Bolting into Cast Aluminu m

Bolt Torque

8.8

(Cast Alumin

um)

10.9

(Cast Alumin

um)

Nominal

Size (A)

ft·lbf

N·m

ft·lbf

N·m

M3

––

1

–

M4

––

2.6 4

M5

––

5.5

8

M6 6 9 9 12

M8 14 20 20 28

M10 28 40 40

55

M12 52 70 73 100

M14

––––

M16

––––

Figure 8.9: Bolt Grades

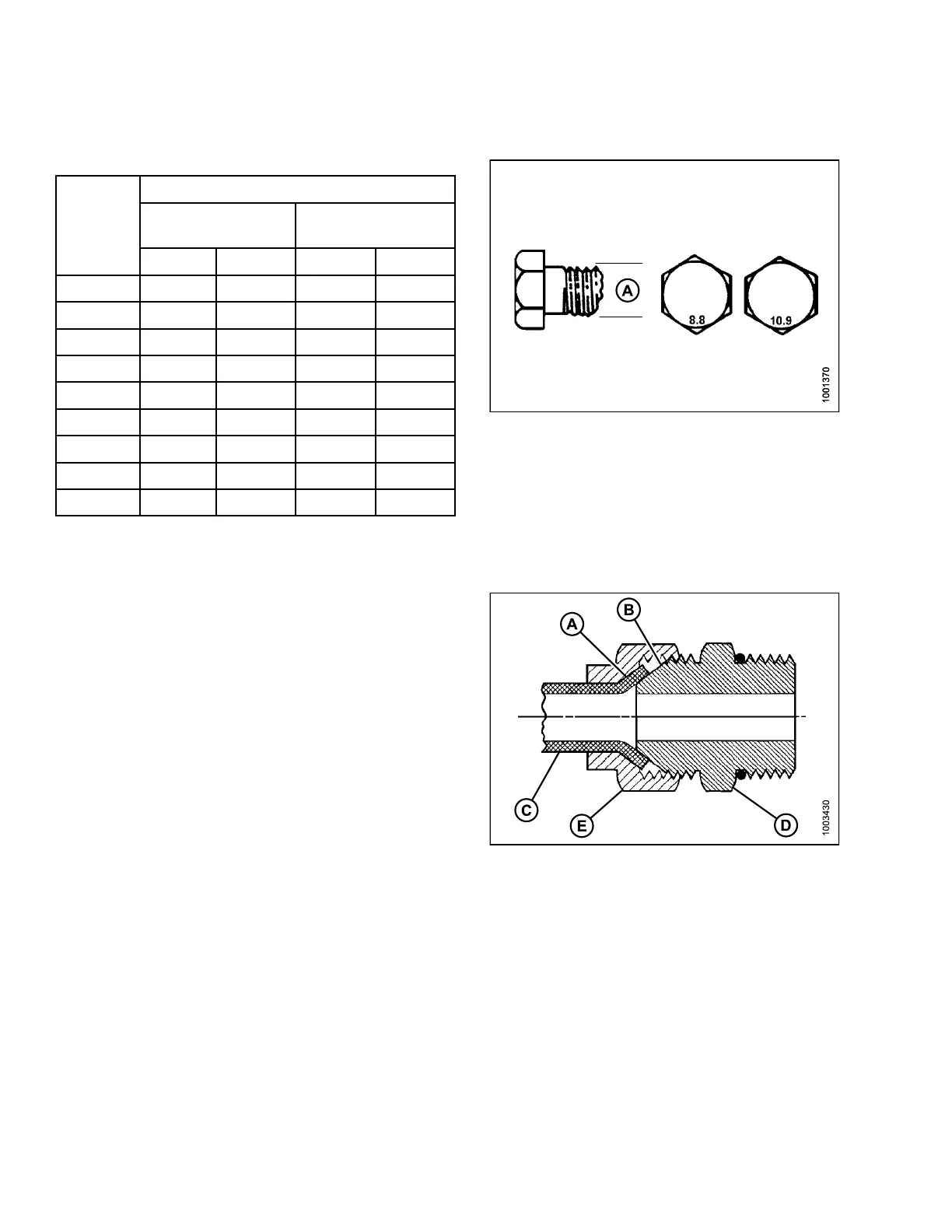

8.1.4 Flare-Type H ydraulic Fittings

1. Check flare (A) and flare seat (B) for defects that might

cause leakage.

2. Aligntube(C)withfitting (D) and thread nut (E) onto

fitting withou t lubrication until contact has been made

between the flared surfaces.

3. Torque the fitting nut (E) to the specified number of

flats from finger tight (FFFT) or to a given torque v alue

in Table 8.10 Flare-Type Hydraulic Tube Fittings, page

439.

4. Use two wrenches to prevent fitting (D) from r otating.

Place one wrench on the fitting body (D) and tighten

nut (E) with the other wrench to the torque shown.

5. Assess the final condition of the connection.

Figure 8.10

: Hydraulic Fitting

147695 438 Revision A

Loading...

Loading...