MAINTENANCE AND SERVICING

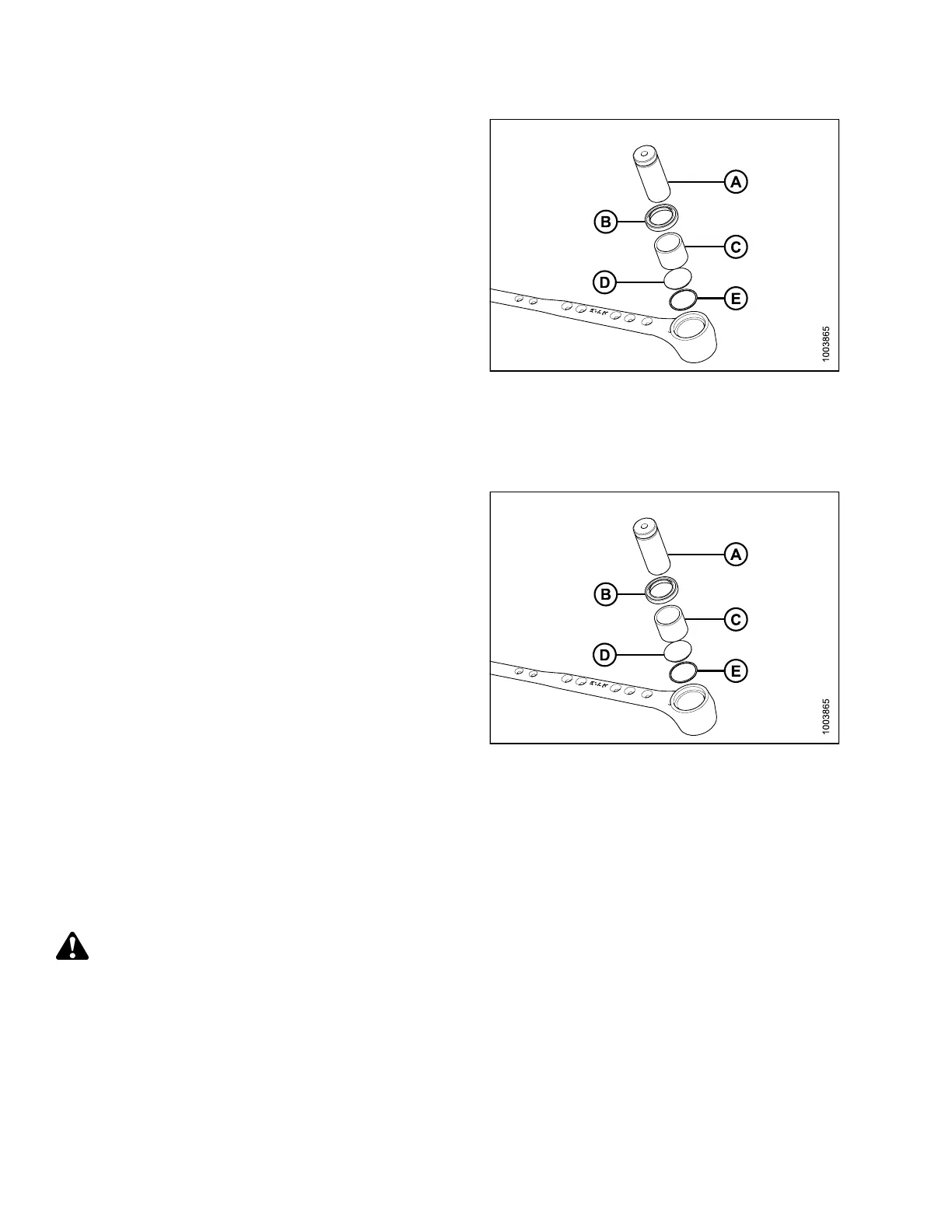

8. Using a flat-ended tool with approximately the same

diameter as pin (A). From the underside of the

knifehead, tap the seal (B), bearing (C), plug (D), and

O-ring (E) from the knifehead.

NOTE:

Seal (B) c an be replaced without removing the

bearing. When changing seal, check pin and needle

bearing for wear. Replace if necessary.

Figure 5.86: Knifehead B earing Assembly

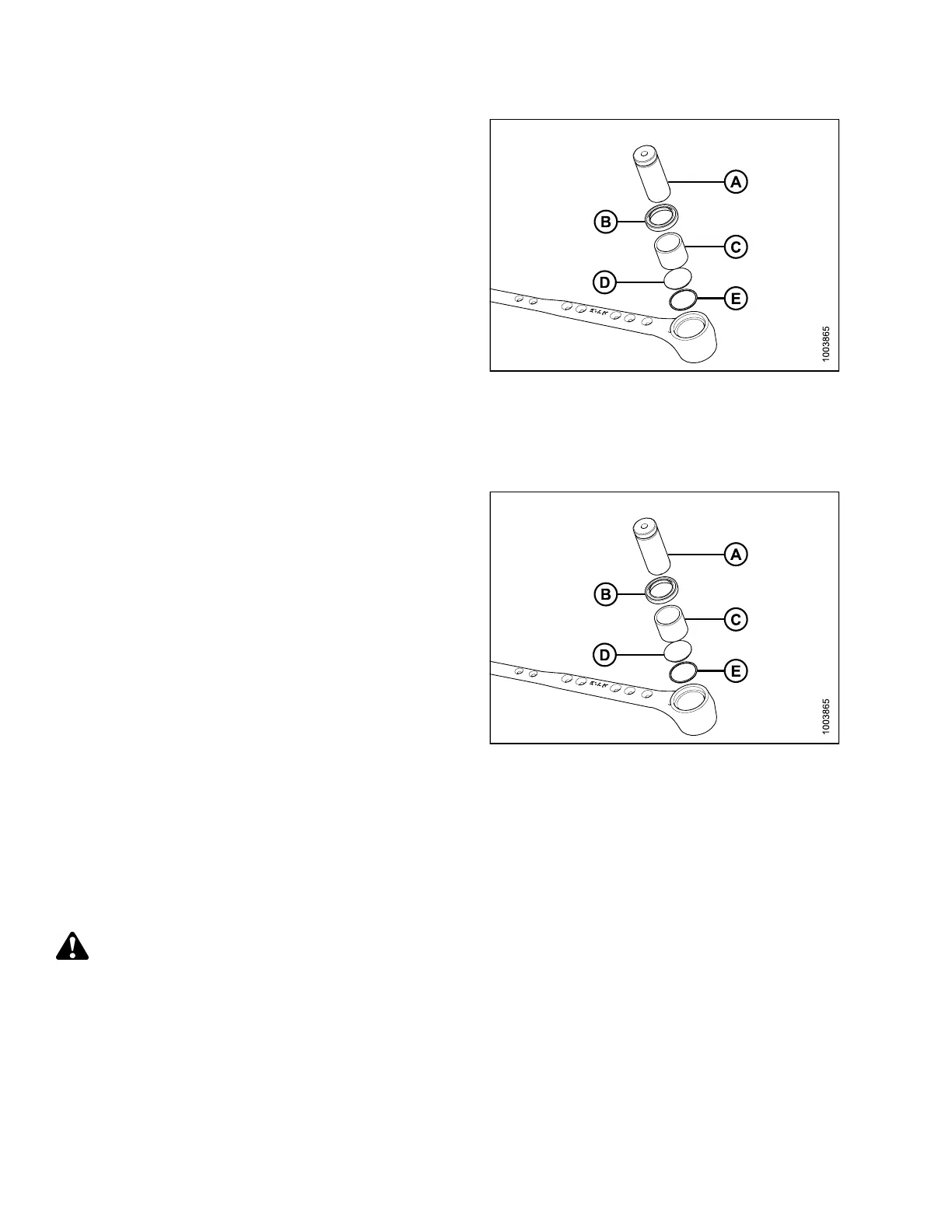

5.8.4 Installing Knifehead Bearing

To install

the knifehead bearing, follow these steps:

1. Place O-ri

ng (E) and plug (D) in knifehead.

IMPORTAN

T:

Install t

he bearing with the stamped end (the end

with iden

tification markin gs) facing up.

2. Using a flat-endedtool (A) with approximately the same

diameter as the bearing (C), push the bearing into the

knifehead until the top of the bearing is flush with the

step in knifehead.

3. Install seal (B) into the knifehead with the lip

facing outw ards.

IMPORTANT:

To avoid premature knifehead or knife drive box

failure, be sure there is no looseness in the fitofthe

knifehead pin and the needle bearing, and the fitof

the knifehead pin and output arm.

4. Install knife. Refer to Installing Knife5.8.5 Installin g

Knife, page 302.

Figure 5.87: Knifehead B earing Assembly

5.8.5 Installing Knife

WARNING

Stand to rear of knife during installation to reduce risk of injury from cutting edges. Wear heavy gloves

when handling knife.

To install a knife, follow these steps:

1. Slide knife into place and align knifehead with the output arm.

147695 302 Revision A

Loading...

Loading...