MAINTENANCE AN D SERVICING

NOTE:

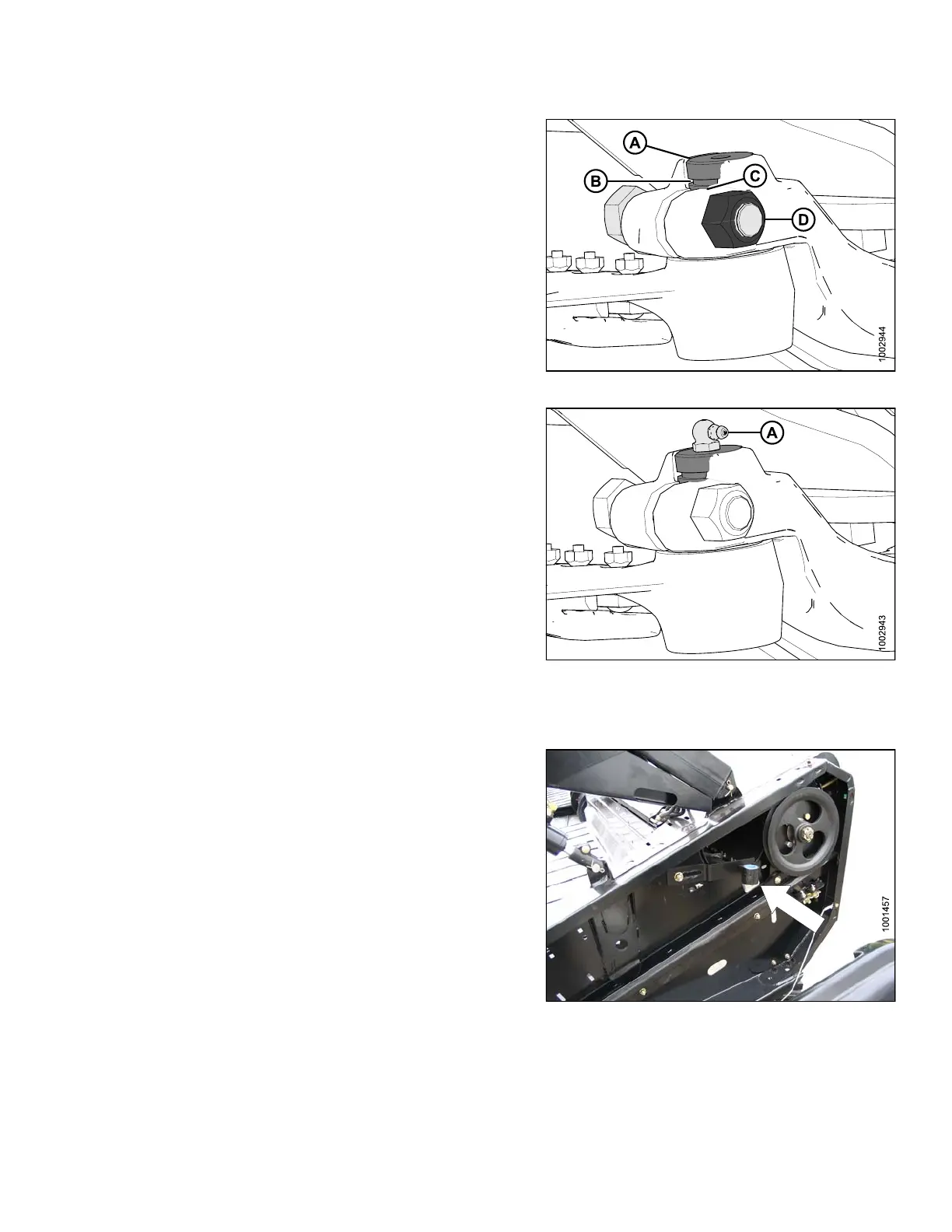

For ease of removing or installing knifehead pin,

remove greas e ze rk from pin.

2. Install knifehead pin (A) through the output arm and

into the knifehead.

3. Set groove (B) in knifehead pin 1/16 in. (1.5 mm)

above (C). Install the 5/8 in. x 3 hex head bolt (D) and

nut and torque to 160 ft·lbf (217 N ·m).

Figure 5.88: Knifehead

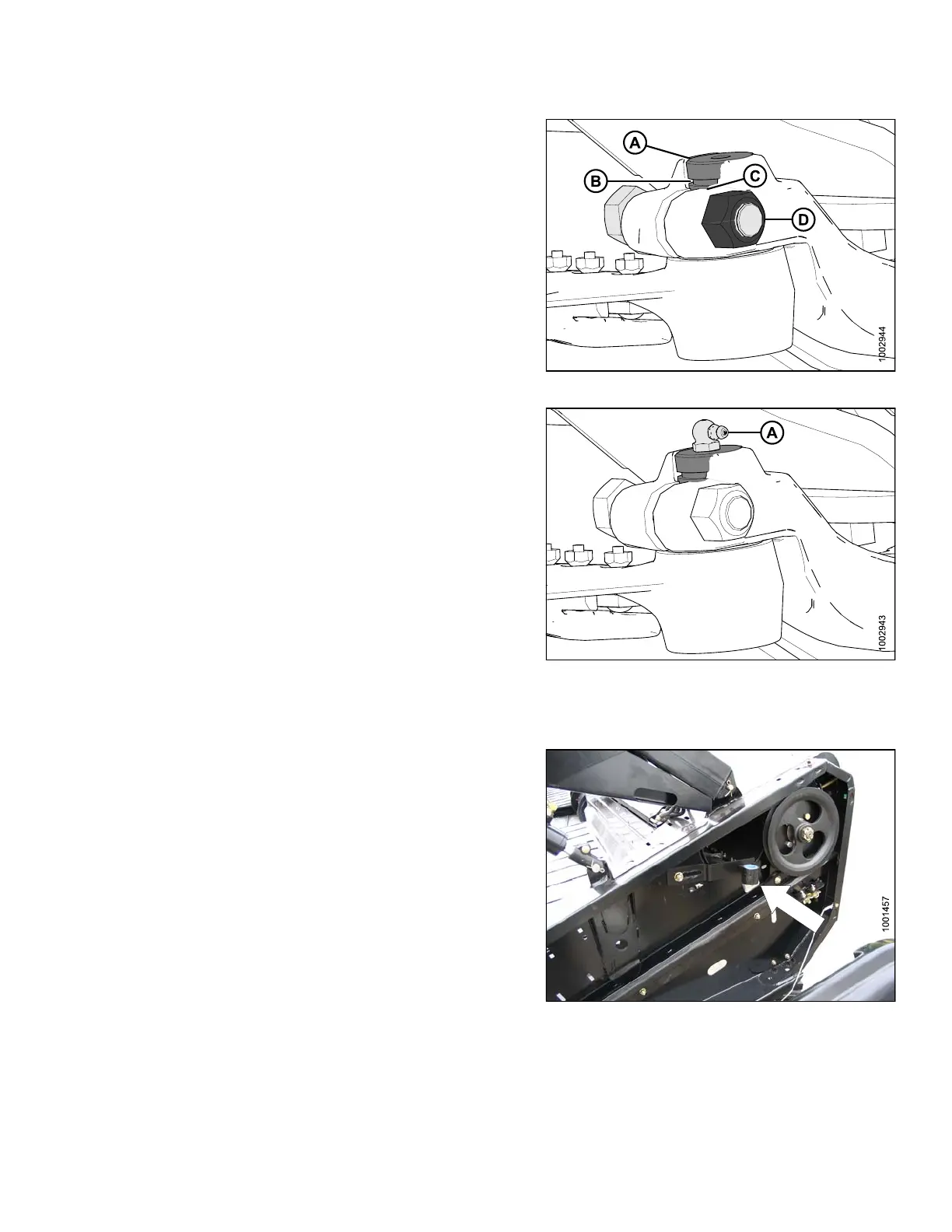

4. Install grease zerk (A) into the knifehead pin, turn the

grease zerk for easy access.

IMPORTAN T:

Grease knifehead just enough to start a slight

downward movement of knifehead. Over-greasing

will lea d to knife misalignm e nt of the knife which

causes guards to overheat and drive systems

to overload.

Figure 5.89: Knifehead

5.8.6 Spare Knife

A spare knife m ay be stored in the header frame tube at

the left end. Ensure knife is secured in place.

Figu

re 5.90: Spare Knife

5.8

.7 Knife Guards

Check DAILY that guards are aligned and that knife sections are contacting shear surface of each guard.

147695 303 Revision A

Loading...

Loading...