MAINTENANCE AND SERVICING

5.2 Maintenance Specifications

5.2.1 Recommended Fluids and Lubricants

Your machine can operate at top efficiency only if clean lubricants are used.

• Use clean containers to handle all lubricants.

• S tore in an area prot ected from dust, moisture, and othe r contaminant s.

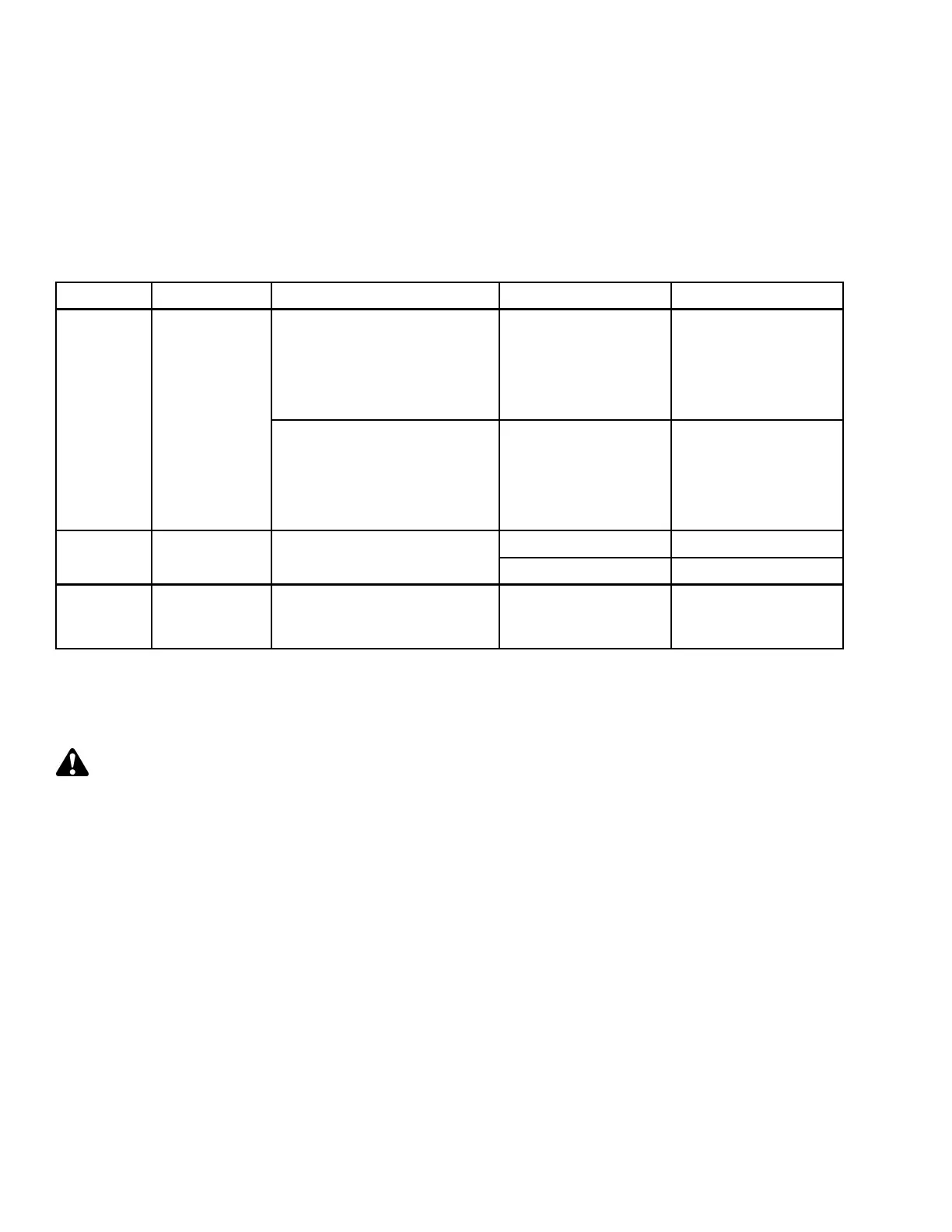

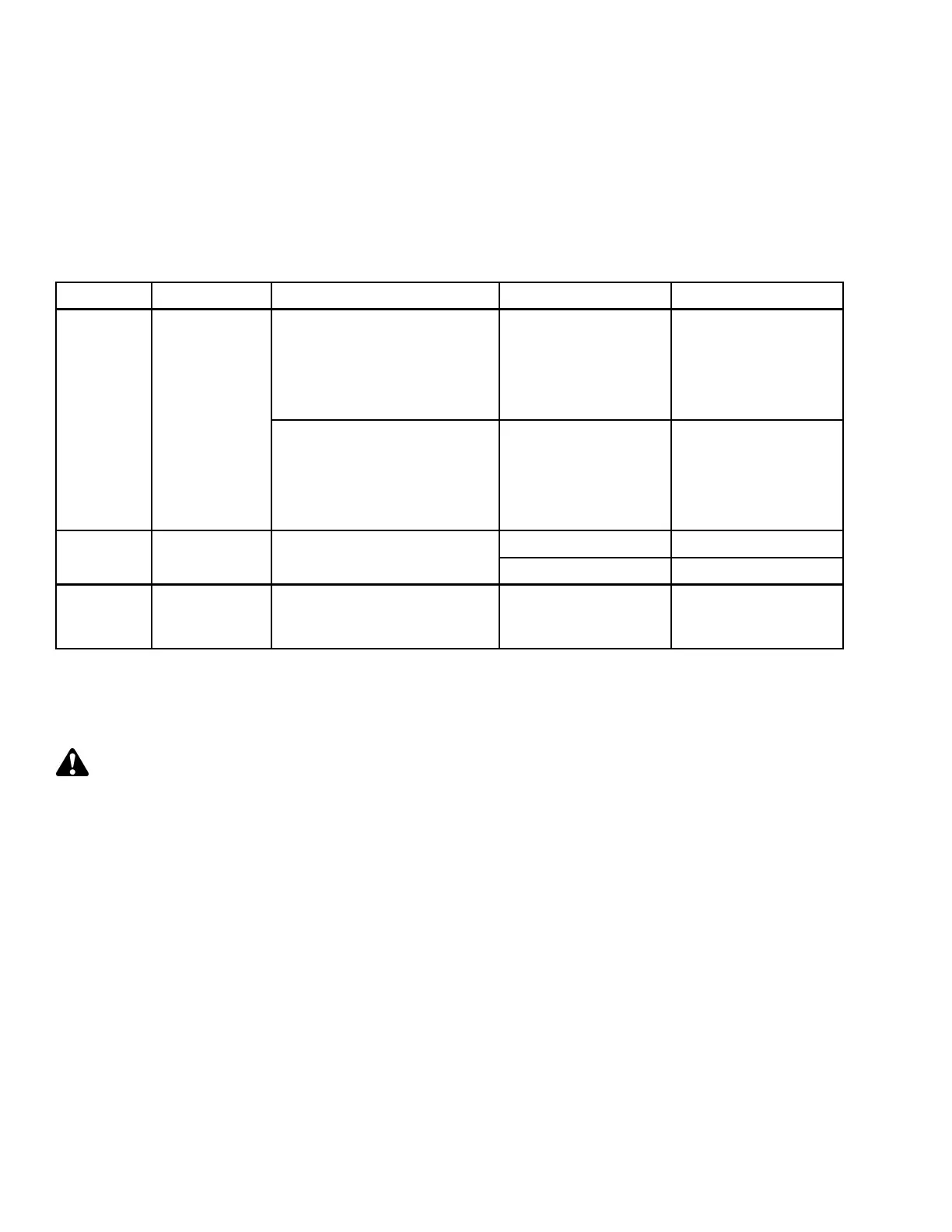

Lubricant

Specification

Description Use

Capacities

High temperature extreme

pressure (EP2) performance

with 1% max. Molybdenum

disulphide (NLGI grade 2)

Lithium base

As required unless

otherwise specified.

—

Grease

SAE

multi-purpose

High tempe

rature extreme

pressure (

EP) performance

with 10% m

ax. Molybdenum

disulphi

de (NLGI grade 2)

Lithium b

ase

Drivelin

e slip-join ts

—

Knife drive box 2.3 quarts (2.2 liters)

Gear

lubricant

SAE 85W-140 API service class G L-5

Main drive gearbox

2.6 quarts (2.5 liter s)

Hydraulic

oil

SAE 15W

-40

Compli

ant with SAE specs for

API cla

ssSJandCH-4engine

oil

Header drive systems

reservoir

16 US ga

llons

(60 lit

ers)

5.2.2 Installing a Roller Chain

To install a roller chain, follow these steps:

DANGE

R

To avoid bodily injury or death from unexpected start-up of machine, always stop engine and remove key

from ignition before leaving operator ’s seat for any reason.

147695 252 Revision A

Loading...

Loading...