MAINTENANCE AN D SERVICING

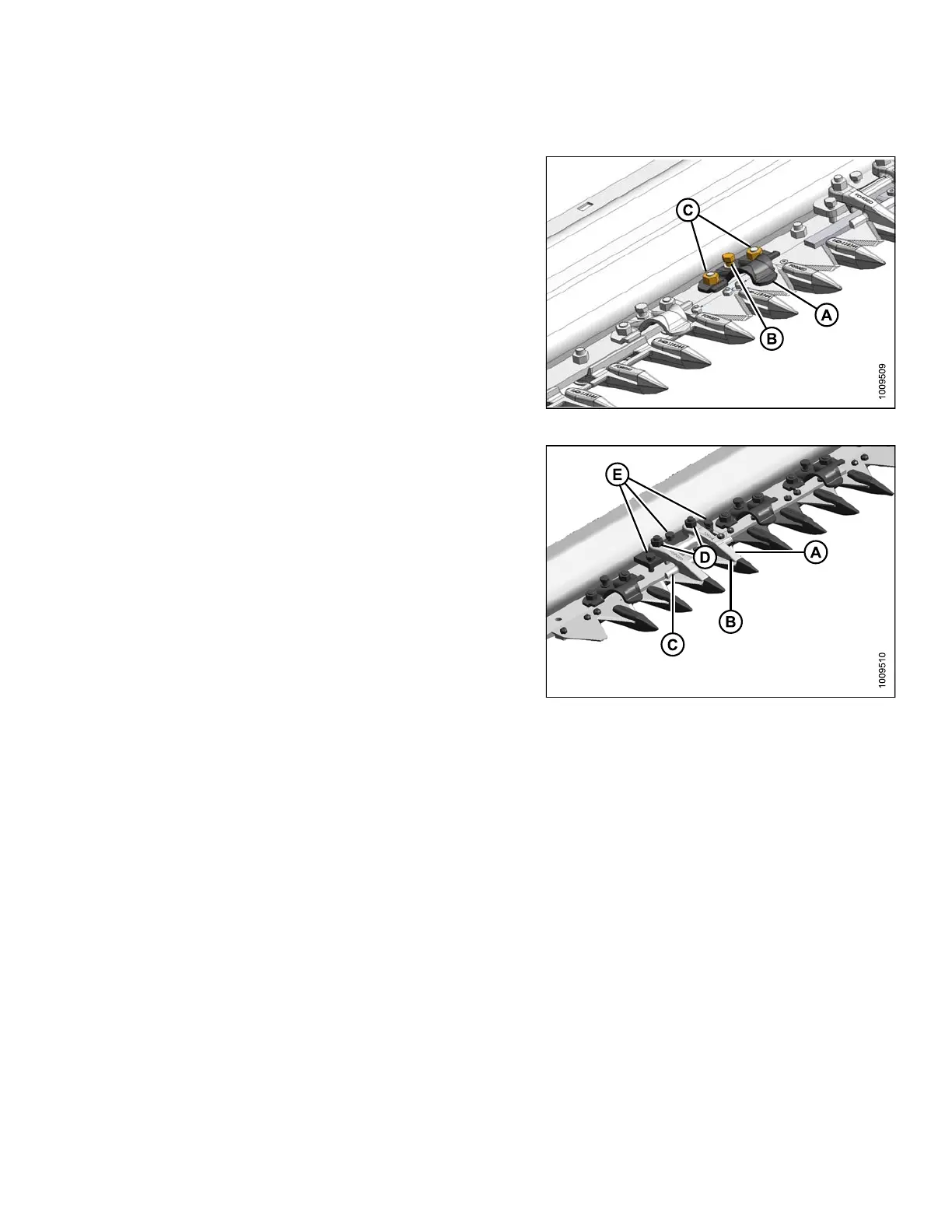

Adjusting Hold-Downs with Pointed Guards

To adjust the clearance betwee n hold-downs and knife on

header with pointed guards, follow these steps:

1. Check the clearance (A) between the normal

hold-down and knife section with a feeler gauge. The

clearance should be 0.004–0.024 in. (0.1–0.6 mm).

2. Adjust as required by turning bolt (B).

NOTE:

Forlargerad

justments, it may be necessary to

loosen nuts

(C), turn adjuster bolt (B), then retighten

nuts (C).

Figure 5.100: Hold-Down Clearance

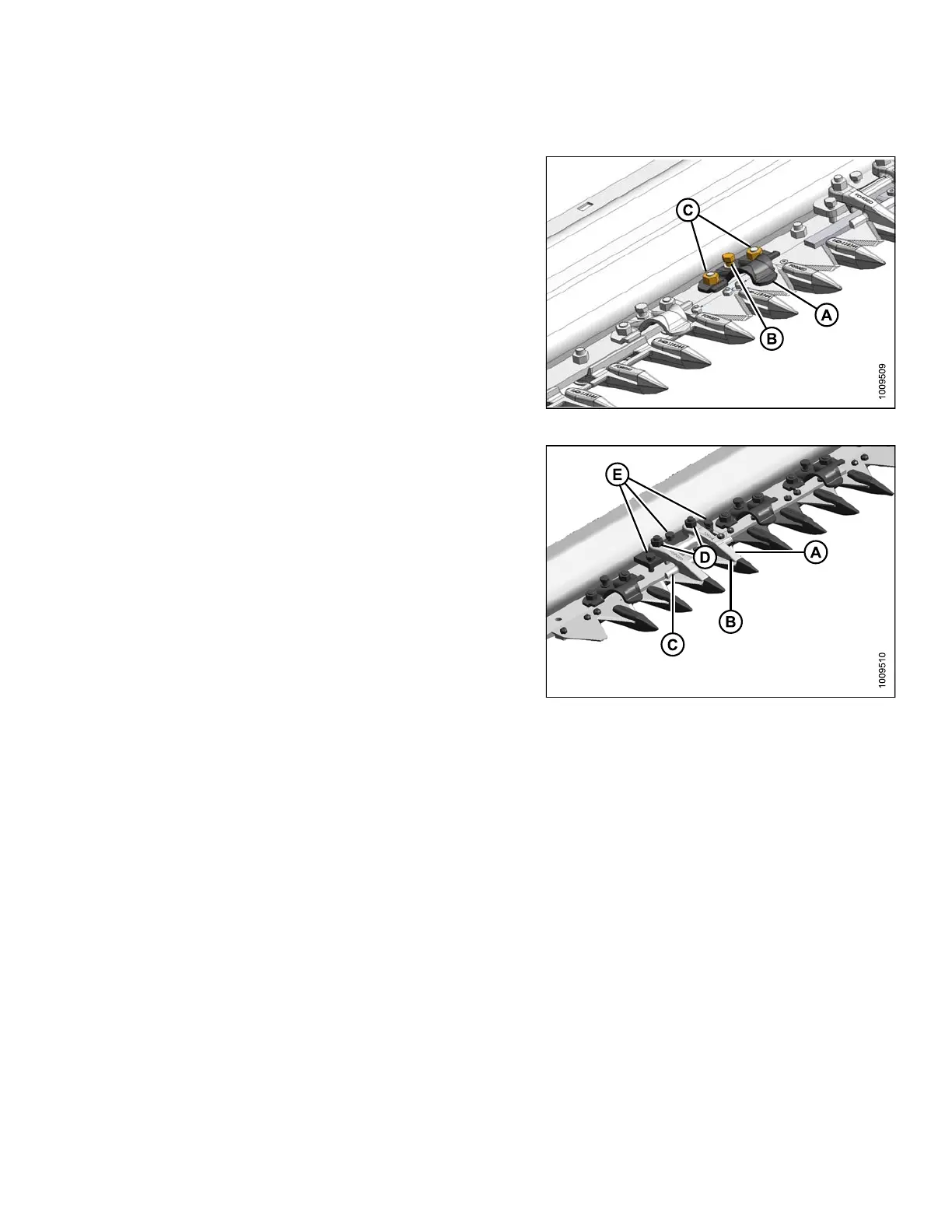

3. Check the clearances between the center guard

hold-down (A) and knife section with a feeler gauge.

The clearances should be:

• 0.004–0.016 in. (0.1–0.4 mm) at guide tip (B)

• 0.004–0.040 in. (0.1–1.0 mm) at rear o f guide (C)

4. If required, adjust clearances as follows:

a. Torque nuts (D) to 35 ft·lbf (46 N·m).

b. Turn the three adjuster bolts (E) as required.

c. Torque nuts (D) to 53 ft·lbf (72 N·m).

5. After adjusting all hold-downs, run header at a low

engine speed and listen for noise due to insufficient

clearance. Insufficient clearance will also result

in overheating of the knife and guards. Readjust

as necessary.

Figure 5.101: Hold-Down Clearance

147695 309 Revision A

Loading...

Loading...