OPERATION

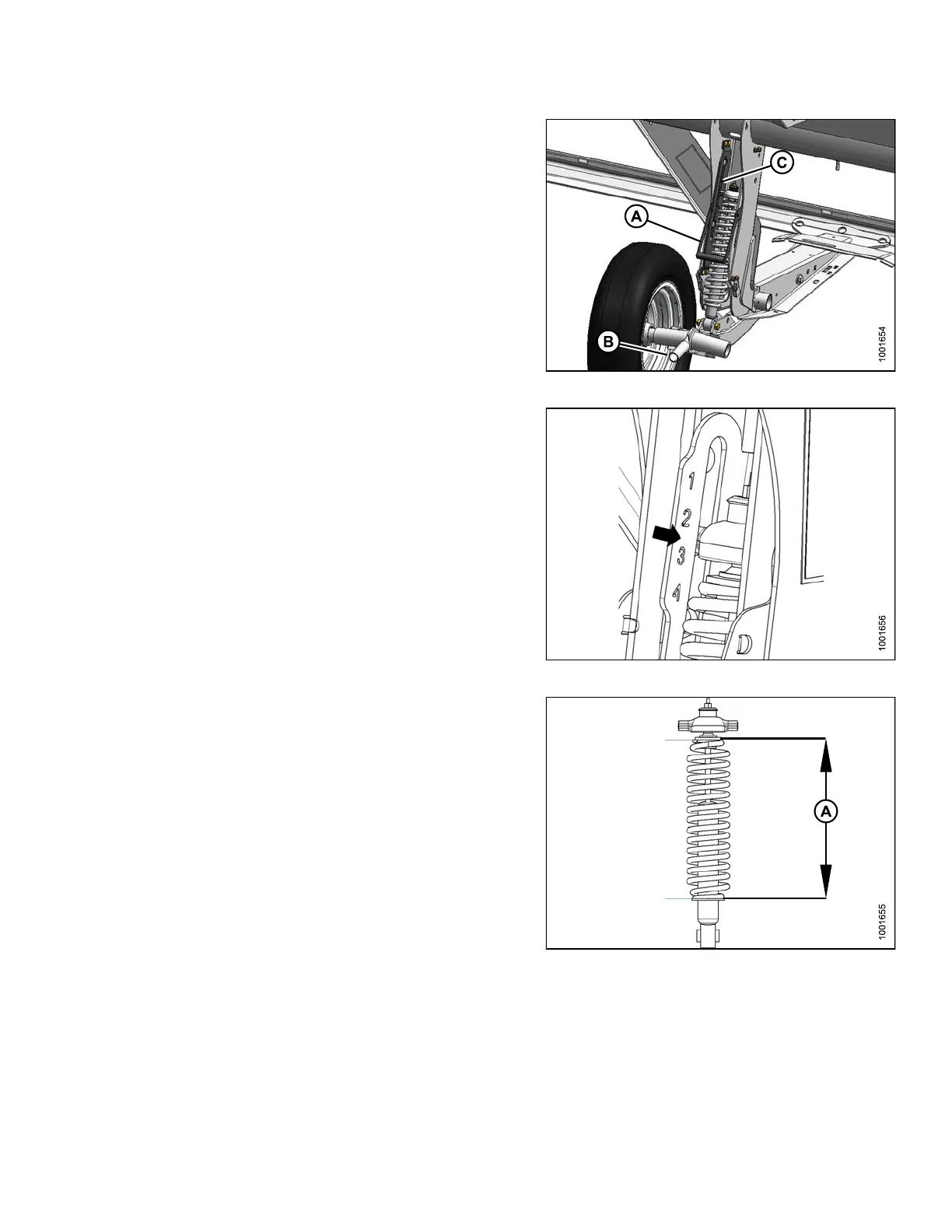

2. Support wheel weight by lifting slightly with one hand

on handle (B). Pull up on handle (A) to release lock.

3. Lift wheel with handle (B) and engage support channel

into center slot (C) in upper support.

4. Push down on handle (A) to lock.

Figure 3.28: Stabilizer Wheel

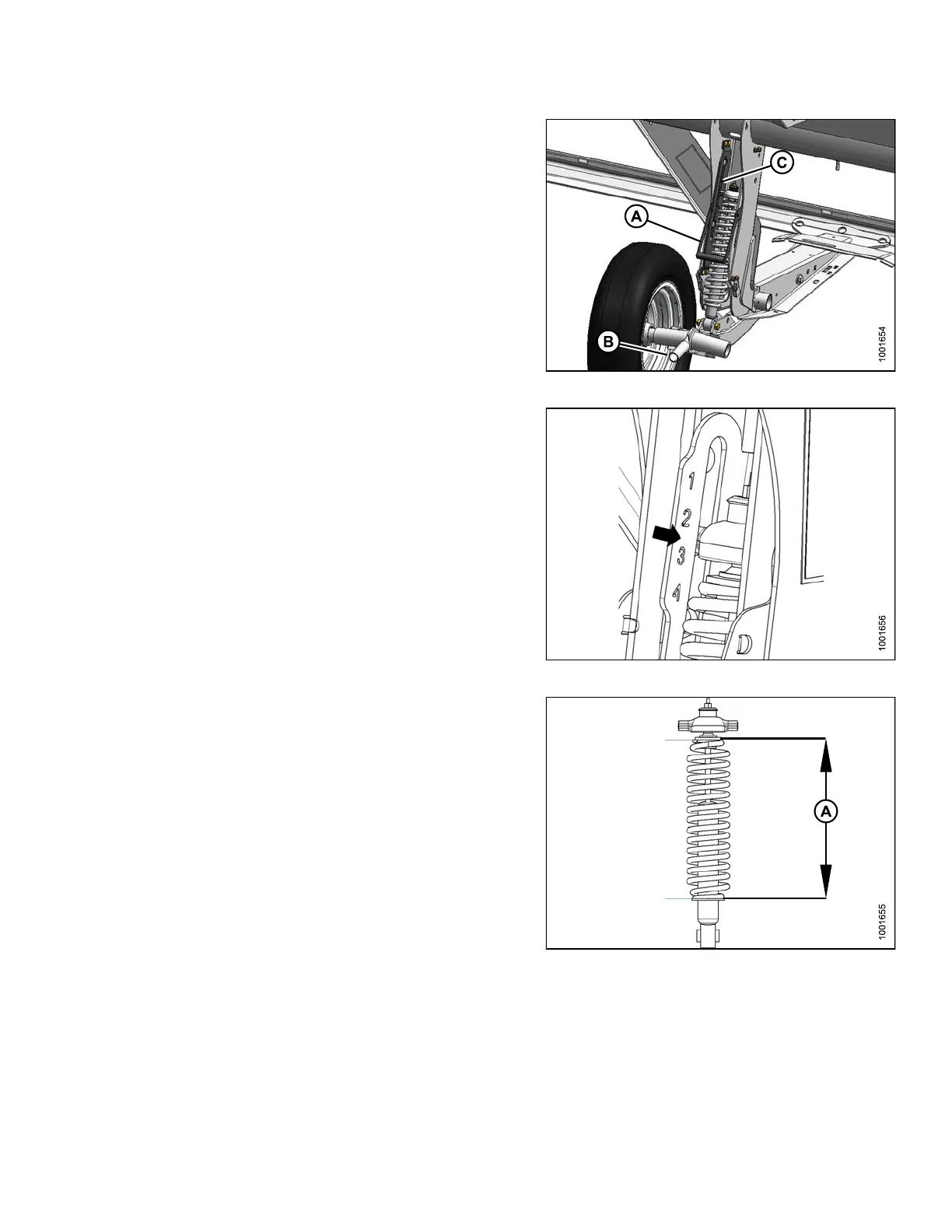

5. Lower header to desired cutting height using

combinecontrols and check load indicator. As an

example the image shows that the wheels are set to a

range between ‘2’and‘3’ on load indicator.

Figure 3.29: Load Indicator

IMPORT

ANT:

Contin

uous operation with excessive spring

compre

ssion (i.e., load indicator reading greater

than ‘4

’ or a compressed length less than

11-5/8

in. [295 mm]) (A) can result in d amage to

suspe

nsion system .

6. Adjust header angle to desired working angle with the

machine’s header angle controls. If angle is not critical,

set it to mid-pos itio n.

7. Use the combine’s Auto Header Height Control

(AHHC) to automatically maintain c uttin g height. Refer

to 3.8 Auto Header Height Control (AHHC), page 89

and your combine operator’s manual for details.

NOTE:

The height sensor on the CA25 adapter must be

connected to the combine height control system in

the cab.

Figure 3.30: Spring Compression

147695 55 Revision A

Loading...

Loading...