• Ink flow flows through the cylinder (3) and over the plunger (4) as the ink pump motor (5) pumps

ink from the cartridge.

• While ink is flowing smoothly, the actuator (6) on the end of the plunger remains outside the gap of

the ink end sensor (7).

• When the ink in a cartridge runs out, the ink pump motor continues to try to draw ink from the ink

port. But with no ink, this creates a negative pressure between the pump and the ink cartridge.

• When the negative pressure (suction) becomes strong enough, it will pull the actuator on the end of

the plunger into the gap of the ink end sensor. This will signal that the ink cartridge has run out of

ink and trigger the ink end alert for the cartridge.

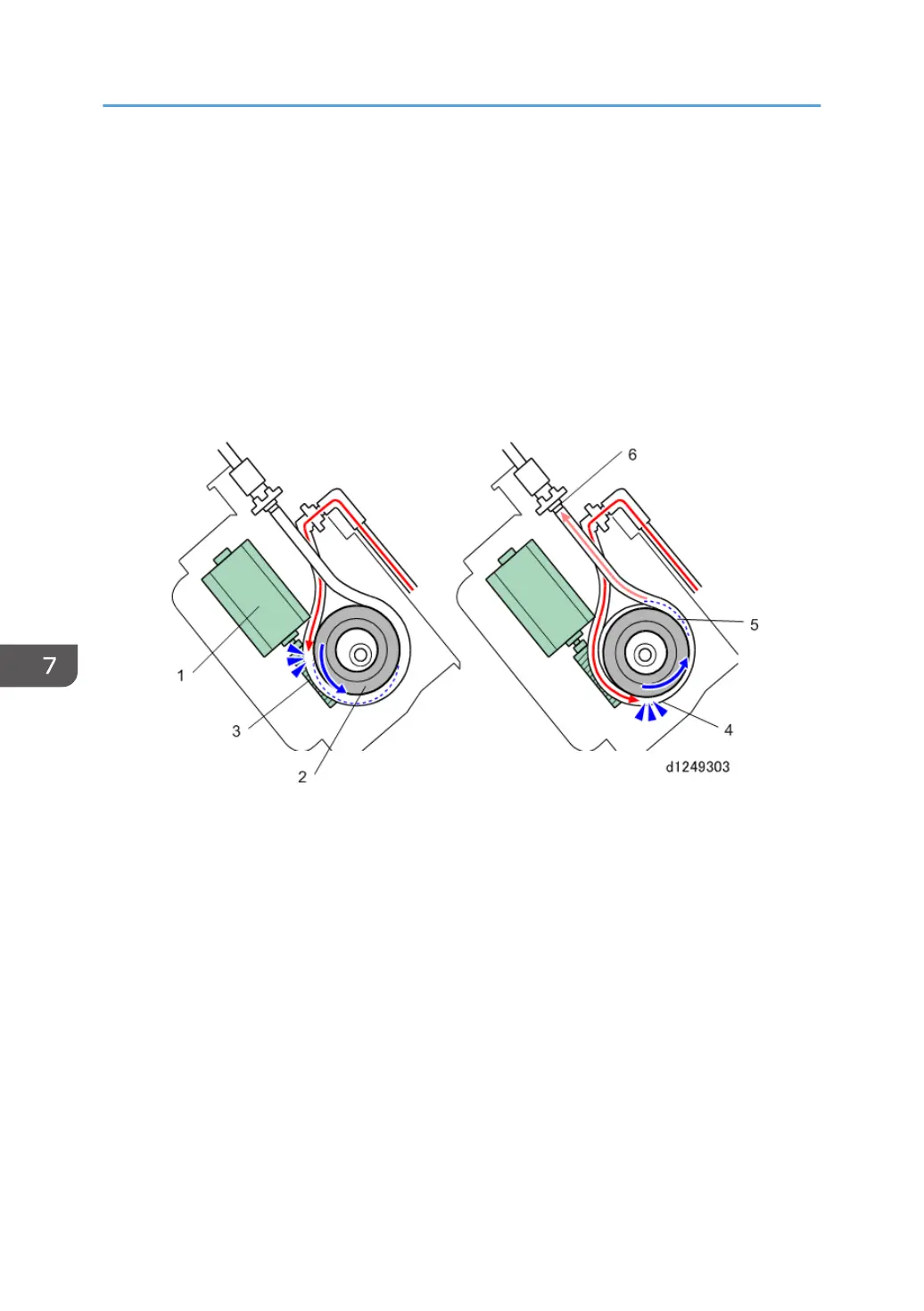

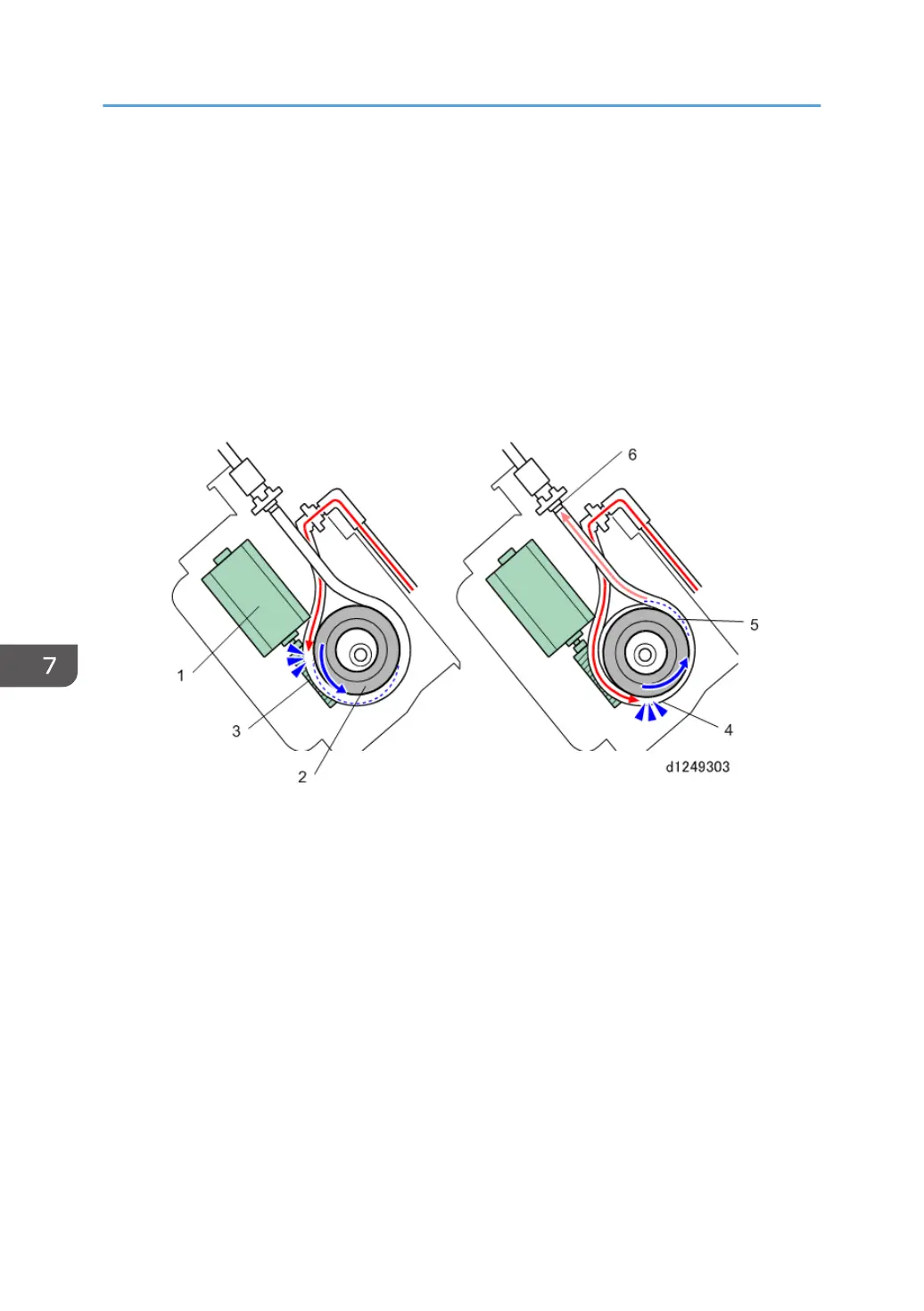

Here is a side view of the ink pump mechanism.

• The ink pump motor (1) drives the ink pump cam (2) counter-clockwise and compresses the ink

supply tube (3).

• The pressure on the tube (4) drives the ink bolus (5) ahead of the cam and creates enough suction

to pull ink through the tube behind the pressure point.

• This action of the cam alternately applying and releasing pressure against the side of the tube

drives the ink out of the pump and into the tube (6) to the carriage unit and print head sub tank

above.

7. Detailed Description

832

Loading...

Loading...