5. After the flushing, if the Nozzle Check Pattern is still not perfect, let the machine remain

idle for 8 hours.

6. Execute three more cleanings and one flushing.

• Be sure to print a Nozzle Check Pattern after each cleaning and the flushing.

• When you have produced an unbroken Nozzle Check Pattern, you can stop.

Faulty Maintenance Unit

• Clean the maintenance unit

• Replace maintenance unit.

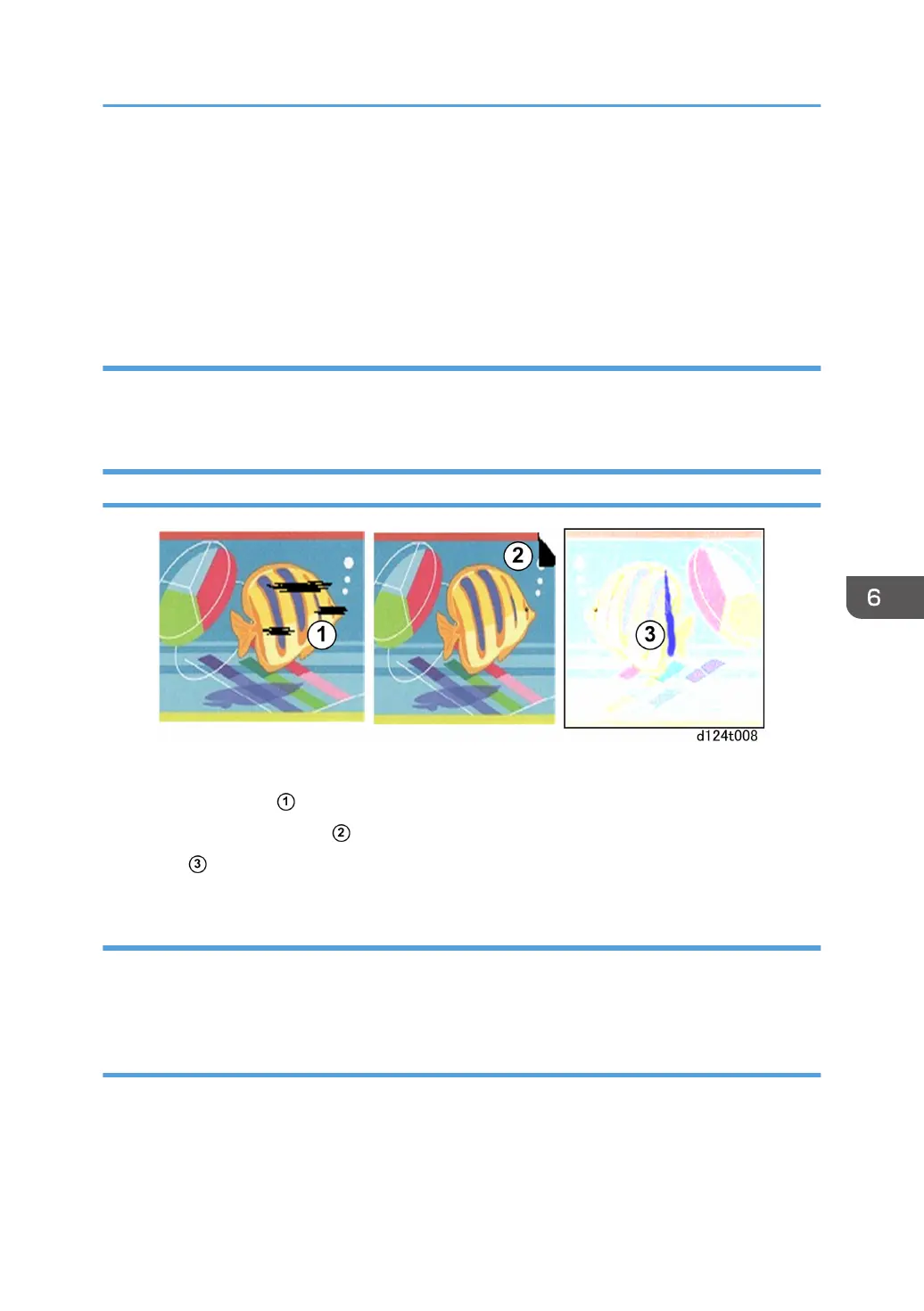

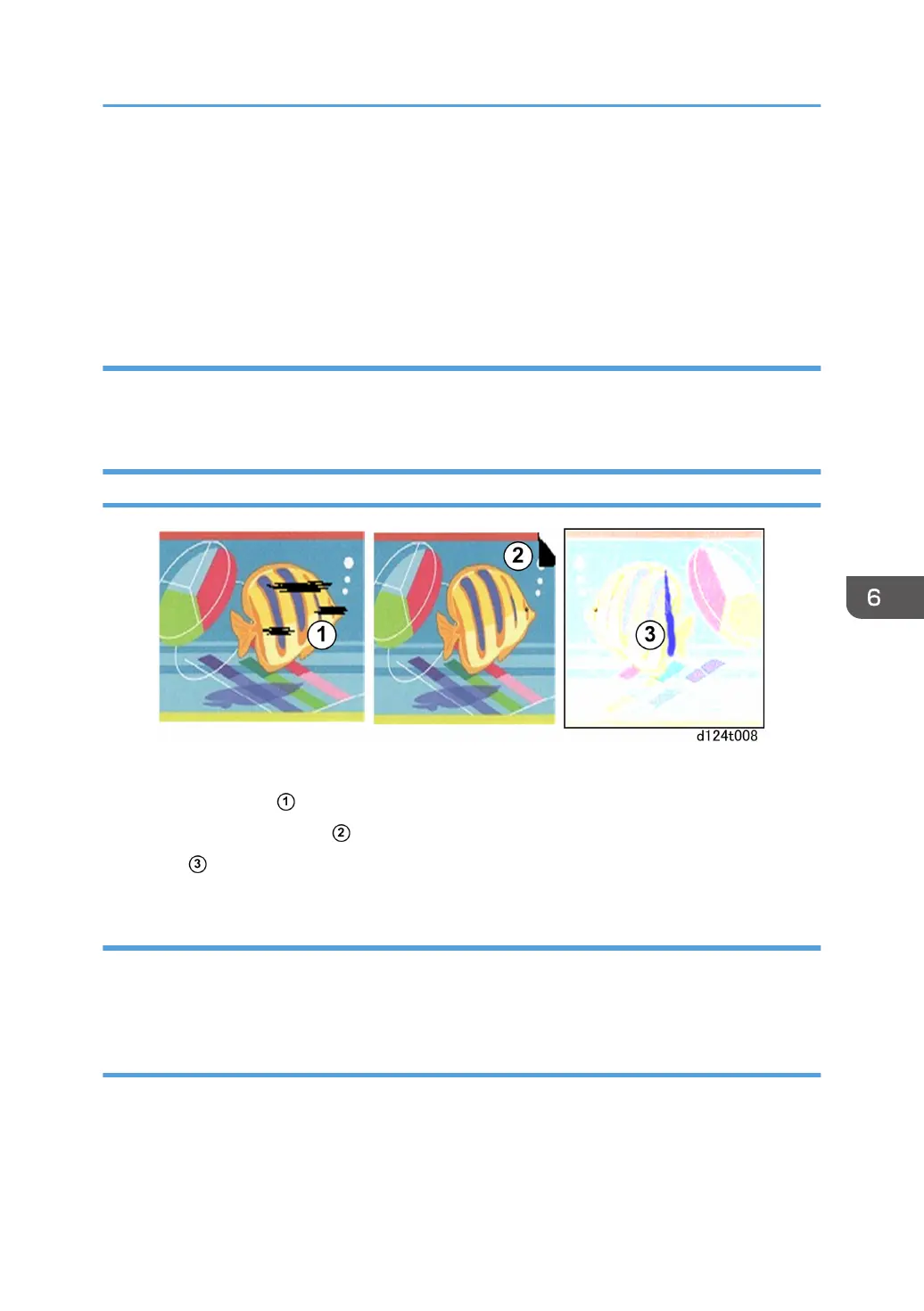

Image Abraded, Paper Torn, Ink Running

Output not clean, paper corner bent

• Print head abrasion

• Dog-eared corner of paper

• Ink run

Gap Adjustment

• Make sure that the gap between the carriage and the platen has been adjusted correctly for the

type and thickness of the paper.

Paper Feed Obstruction

• Inspect the platen for paper fragments or dirty plates. Clean the plates.

• Check around the carriage unit for paper fragments.

• Check around the maintenance unit for paper fragments.

Printing Problems

729

Loading...

Loading...